Single-chip three-axis magnetic sensor

A magnetic sensor and three-axis magnetic technology, applied in the field of magnetic sensing, can solve the problems of unfavorable accurate measurement of three-dimensional magnetic fields, incomplete symmetry of triangular bulges, deviations, etc., to improve performance and yield, reduce production costs, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

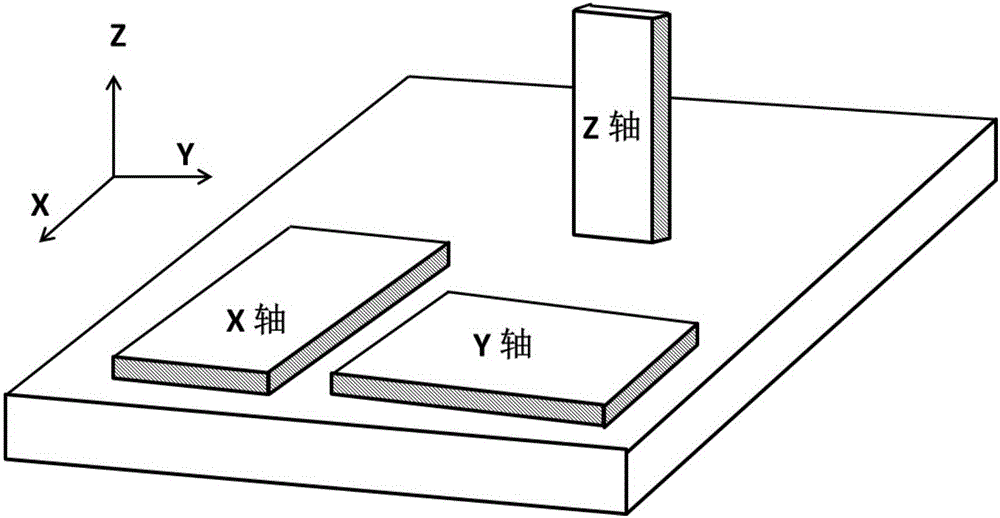

[0044] see Figure 4 , Figure 5 , The present invention discloses a single-chip three-axis magnetic sensor, which includes: an X-axis magnetic sensor 10 , a Y-axis magnetic sensor 20 , and a Z-axis magnetic sensor 30 .

[0045] The X-axis magnetic sensor 10 and the Y-axis magnetic sensor 20 are located in plane 1, and the Z-axis magnetic sensor 30 is designed through a Wheatstone bridge. The Z-axis magnetic sensor 30 includes four groups of Z-axis magnetoresistive sensing elements to form a Wheatstone bridge. bridge.

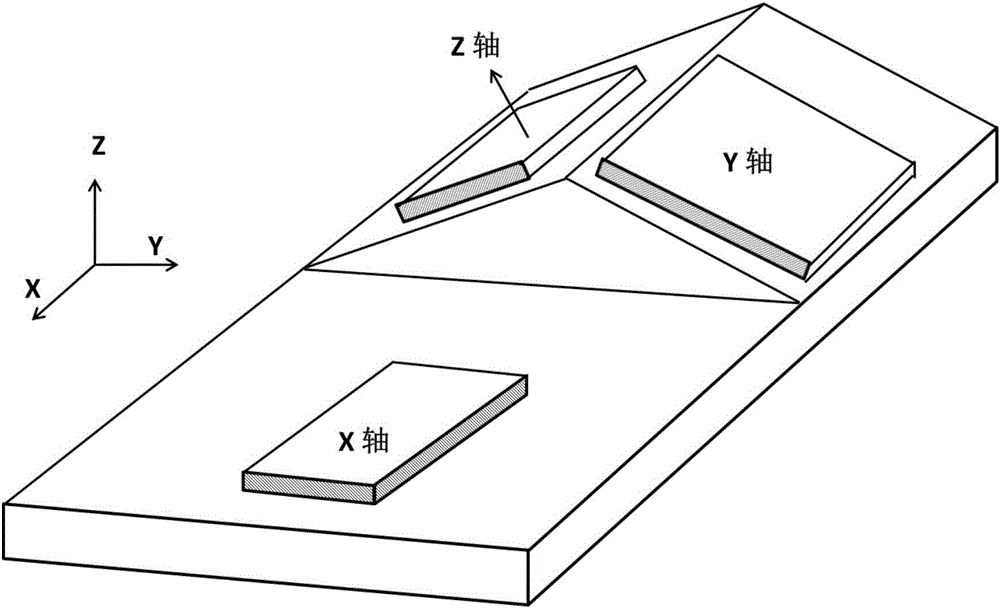

[0046] The Z-axis magnetoresistive sensing element includes a Z-axis magnetoresistive sensing unit 4 and a conductor unit 5; the Z-axis magnetoresistive sensing element is respectively arranged on both sides of the slope of the set inclination angle, and the Z-axis magnetoresistance sensor is changed simultaneously. The orientation angle of the conductor unit of the measuring element finally reaches the Z-axis magnetoresistive sensing element only measures th...

Embodiment 2

[0060] A single-chip three-axis magnetic sensor, the three-axis magnetic sensor includes: an X-axis magnetic sensor, a Y-axis magnetic sensor, and a Z-axis magnetic sensor.

[0061] The X-axis magnetic sensor and the Y-axis magnetic sensor are located in the plane, and the Z-axis magnetic sensor adjusts the Z-axis magnetic resistance at the same time through the Z-axis magnetoresistive sensing unit and the conductor unit arranged on both sides of the slope and the base plane connected to the slope. The initial magnetization direction of the sensing unit, the orientation of the conductor unit and the positions of the magnetoresistive sensing unit and the conductor unit on the slope achieve a Z-axis magnetic sensor that only senses the vertical magnetic field but not the horizontal magnetic field.

[0062] In summary, the single-chip three-axis magnetic sensor proposed by the present invention can improve measurement accuracy and reduce production costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com