Manufacturing method of embedded epitaxial layer

A manufacturing method and epitaxial layer technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of reducing carrier mobility in the channel region, collapse of the silicon-germanium main layer 106b, and reducing device performance, etc. Achieve size reduction, low cost, improve performance and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

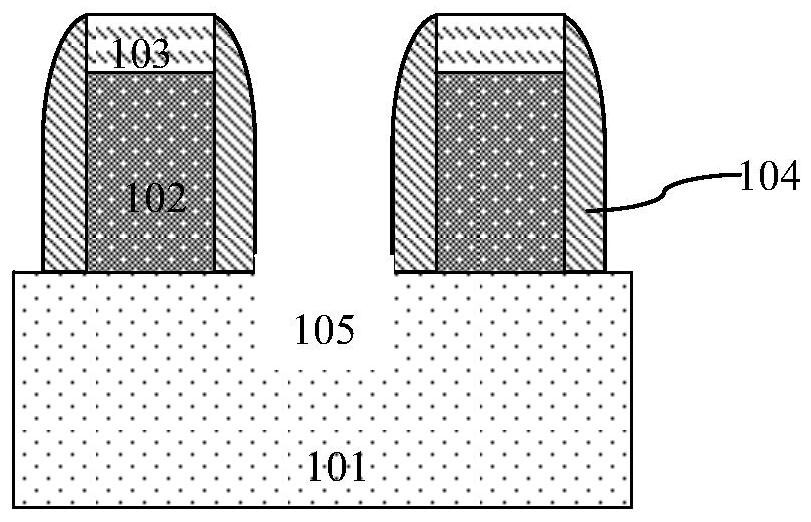

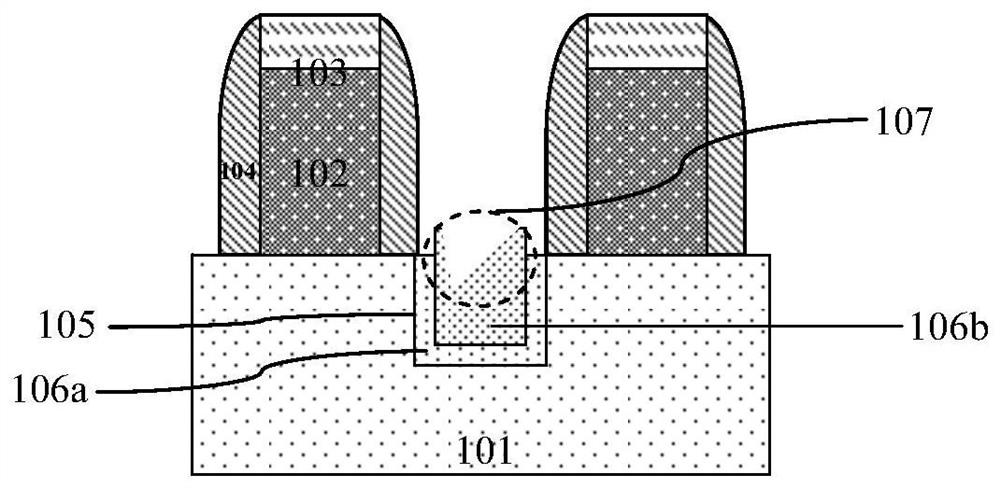

[0064] Such as Figure 4 As shown, it is a flow chart of the manufacturing method of the embedded epitaxial layer 6 according to the embodiment of the present invention; as Figure 5A to Figure 5D As shown, it is a schematic diagram of the device structure in each step of the manufacturing method of the embedded epitaxial layer 6 in the embodiment of the present invention; the manufacturing method of the embedded epitaxial layer 6 in the embodiment of the present invention includes the following steps:

[0065] Step 1, such as Figure 5A As shown, the silicon substrate 1 is etched to form grooves 5 .

[0066] A gate structure is formed on the silicon substrate 1, and the groove 5 is self-aligned and formed on two sides of the gate structure.

[0067] The gate structure includes a gate dielectric layer and a polysilicon gate 2 stacked in sequence.

[0068] The top of the polysilicon gate 2 is covered with a top hard mask layer 3 , and side walls 4 are formed on the side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com