High-strength fireproof wooden door

A high-strength, wooden door technology, used in fire doors, door leaves, windows/doors, etc., can solve the problems of high moisture content, high loss of core material quality on ignition, glue, etc., to achieve good fire resistance, high mechanical strength, Durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

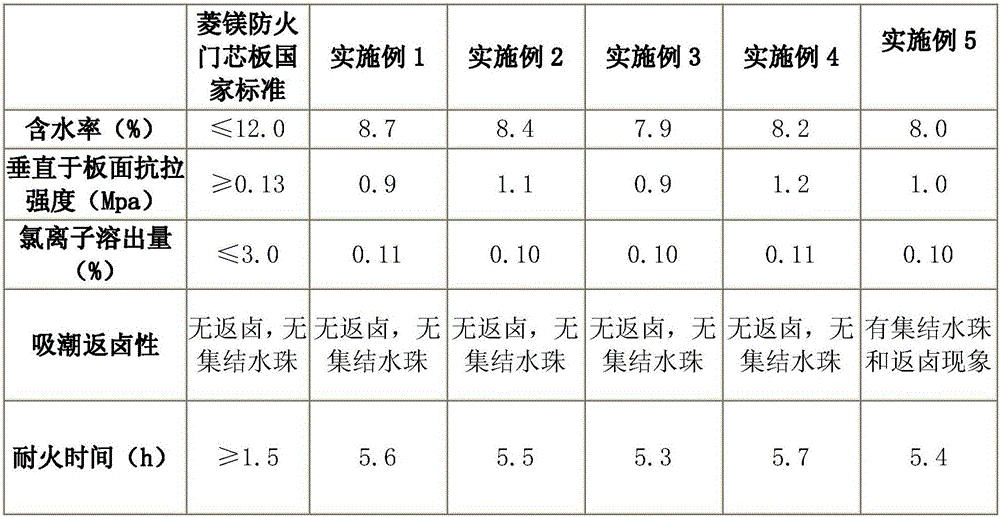

Examples

Embodiment 1

[0024] A method for producing a high-strength fireproof wooden door, the steps of which are as follows:

[0025] (1) Prepare door core board:

[0026] Prepare raw materials according to the following parts by weight:

[0027] 10 parts of lightly burned magnesia powder, 2 parts of magnesium sulfate, 0.05 parts of chitosan, 0.05 parts of magnesium aluminum spinel, 0.6 parts of pine wood chips, 1.5 parts of sodium starch octenyl succinate, 0.8 parts of phosphate starch, 0.1 parts Tourmaline powder, 1 part of andalusite powder, 0.8 part of silicone water repellent powder, 0.08 part of nano silicon dioxide, 0.1 part of polypropylene fiber, 8 parts of water and 3 parts of foam;

[0028] Dissolving magnesium sulfate makes magnesium sulfate solution;

[0029] Add other raw materials except the foam into the magnesium sulfate solution in proportion and stir evenly, then add the foam and mix evenly to obtain the slurry;

[0030] Put the slurry at 5°C for 50 minutes, then raise the te...

Embodiment 2

[0038] A method for producing a high-strength fireproof wooden door, the steps of which are as follows:

[0039] (1) Prepare door core board:

[0040] Prepare raw materials according to the following parts by weight:

[0041] 10 parts of lightly burned magnesia powder, 2.5 parts of magnesium sulfate, 0.05 parts of chitosan, 0.05 parts of magnesium aluminum spinel, 0.6 parts of pine wood chips, 1 part of sodium starch octenyl succinate, 0.8 parts of phosphate ester starch, 0.2 parts Tourmaline powder, 0.8 parts of andalusite powder, 0.8 parts of silicone water repellent powder, 0.08 parts of nano silicon dioxide, 0.1 parts of polypropylene fiber, 10 parts of water and 2 parts of foam;

[0042] Dissolving magnesium sulfate makes magnesium sulfate solution;

[0043] Add other raw materials except the foam into the magnesium sulfate solution in proportion and stir evenly, then add the foam and mix evenly to obtain the slurry;

[0044] Put the slurry at 5°C for 50 minutes, then ...

Embodiment 3

[0052] A method for producing a high-strength fireproof wooden door, the steps of which are as follows:

[0053] (1) Prepare door core board:

[0054] Prepare raw materials according to the following parts by weight:

[0055] 10 parts of lightly burned magnesia powder, 2.1 parts of magnesium sulfate, 0.05 parts of chitosan, 0.05 parts of magnesium aluminum spinel, 0.6 parts of pine wood chips, 1.4 parts of sodium starch octenyl succinate, 0.8 parts of phosphate starch, 0.1 parts Tourmaline powder, 0.9 parts of andalusite powder, 0.8 parts of silicone water repellent powder, 0.08 parts of nano silicon dioxide, 0.1 parts of polypropylene fiber, 9 parts of water and 3 parts of foam;

[0056] Dissolving magnesium sulfate makes magnesium sulfate solution;

[0057] Add other raw materials except the foam into the magnesium sulfate solution in proportion and stir evenly, then add the foam and mix evenly to obtain the slurry;

[0058]Put the slurry at 5°C for 50 minutes, then raise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com