Unilateral formwork supporting construction method for basement exterior wall on basis of steel pipe truss

A technology for basement exterior walls and steel pipe trusses, which is applied in the direction of basic structure engineering, formwork/formwork/working frame connectors, walls, etc. It is prone to deformation and other problems, and achieves the effect of low construction cost, improved stability and lateral support ability, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

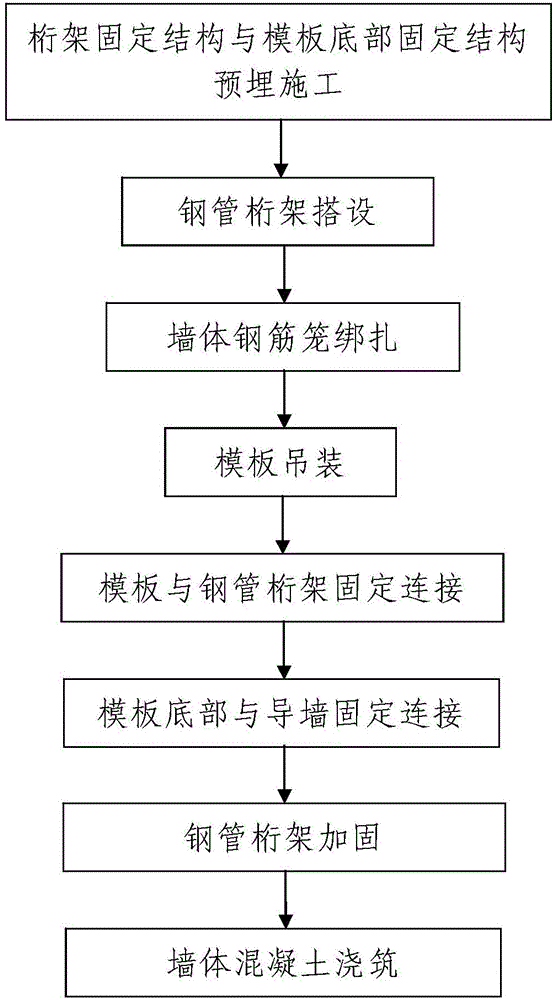

[0058] Such as figure 1 A single-side formwork construction method for basement exterior walls based on steel pipe trusses shown includes the following steps:

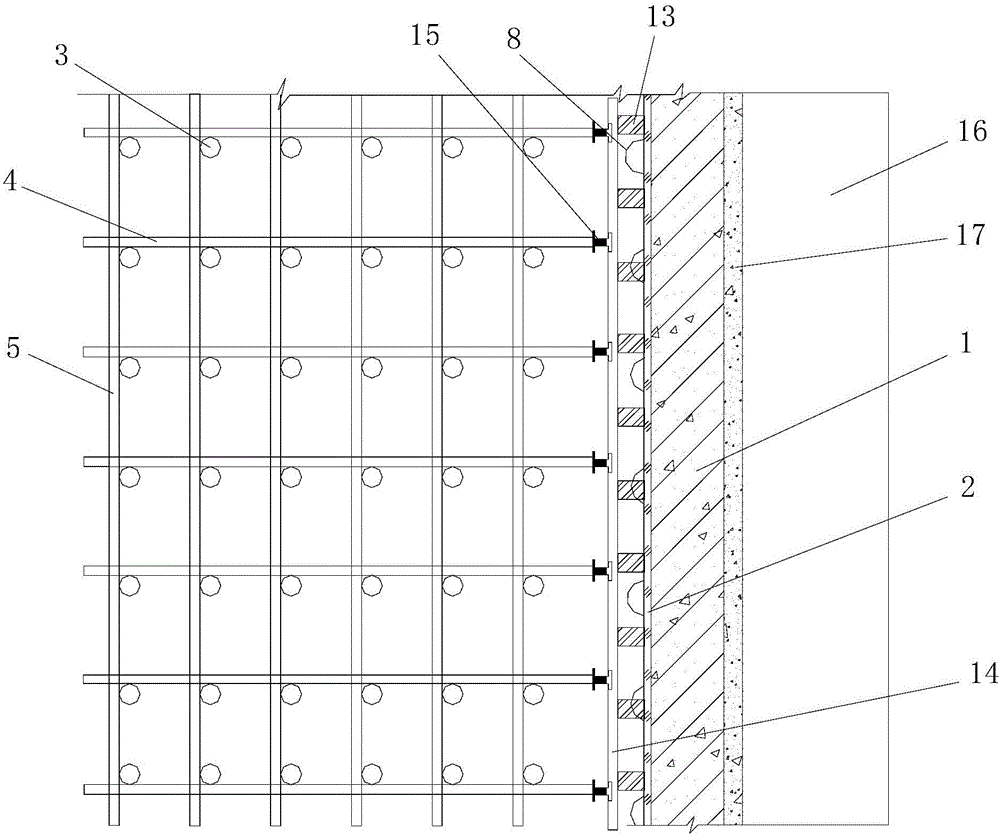

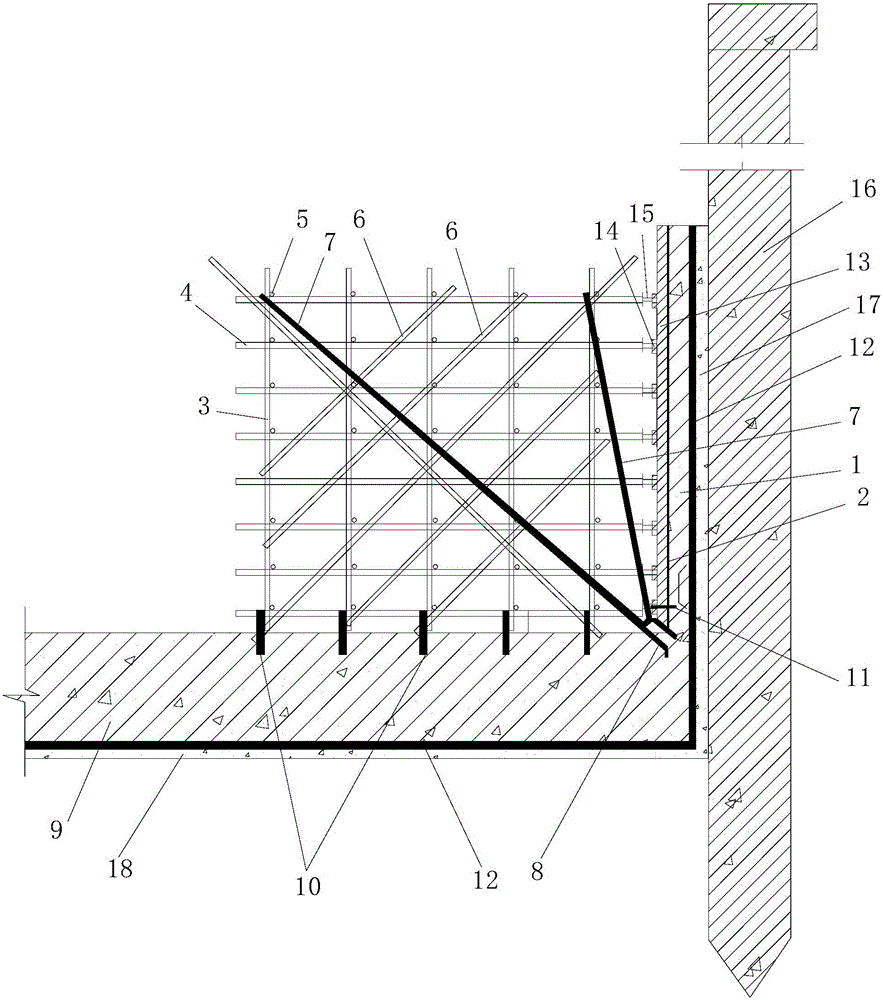

[0059] Step 1. Pre-embedded construction of the fixed structure of the truss and the fixed structure at the bottom of the formwork: pre-embed the fixed structure of the truss used to fix the steel pipe truss on the support foundation 9, and pre-embed the fixed structure at the bottom of the formwork used to fix the formwork 2 on the guide wall, See details figure 2 and image 3 ;

[0060] Such as figure 2 and image 3 As shown, the formwork 2 is supported on the inner side of the basement wall 1 to be constructed, and the formwork 2 is arranged vertically; the basement wall 1 to be constructed is supported on a supporting foundation 9, and the supporting foundation 9 is a steel bar Concrete structure; the guide wall is a reinforced concrete guide wall located on the support foundation 9; the steel pipe truss is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com