Melt-blow oil absorption material

An oil-absorbing material and melt-blown technology, applied in the direction of adsorption of water/sewage treatment, water/sludge/sewage treatment, non-woven fabrics, etc., can solve the problem of oil absorption, oil absorption ratio, oil retention, reusable performance, and high density , high processing costs and other issues, to achieve the effect of good hydrophobicity, mature technology and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

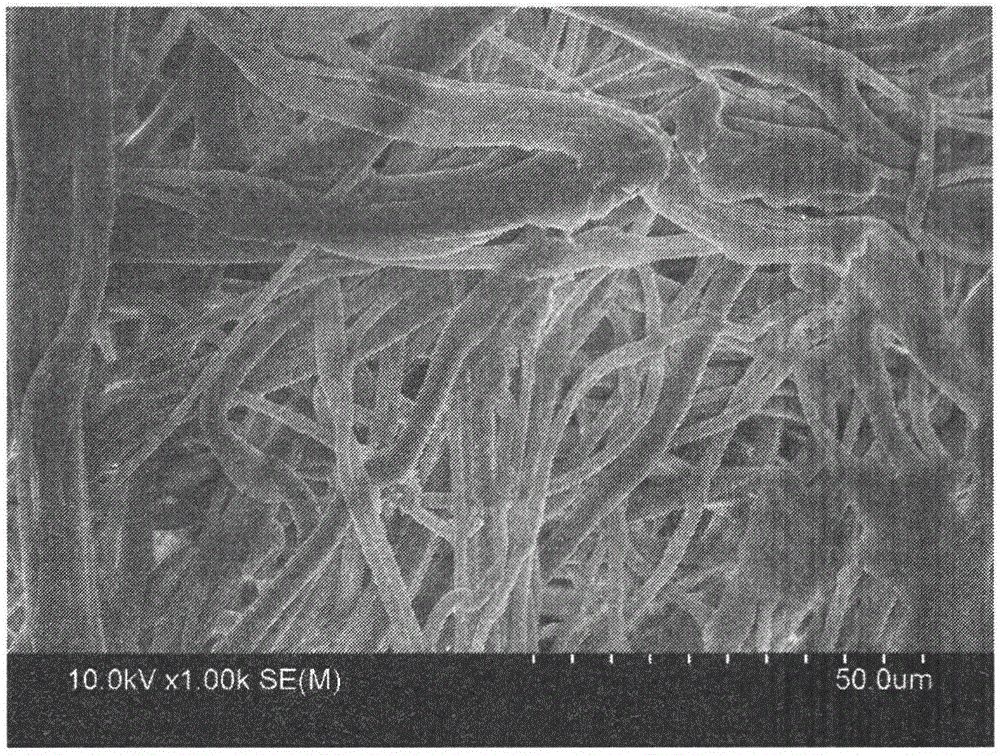

Image

Examples

Embodiment 1

[0013] Set the density to 0.90g / cm 3 , the melt index is 1000g / 10min, the mass percentage is 95% polypropylene and the density is 1.04g / cm 3 , polystyrene with a melt index of 20g / 10min and a mass percentage of 5% is placed in a high-speed mixer and mixed evenly at high speed, then added to a screw extruder to melt and extrude, and then enters the melt blown through the material path and metering pump Die head, the melt meets high-speed hot air at the outlet of the melt-blown die head, and is drawn and refined under the action of high-speed hot air, and then deposited on the net curtain to form polystyrene / polypropylene blended melt-blown oil-absorbing material . After testing, the crystallinity of the oil-absorbing material is 20%, the oil absorption rate reaches 8.6g / g, the absorption saturation can be reached within 6 minutes, and the oil retention rate is 85.5%.

Embodiment 2

[0015] Set the density to 0.90g / cm 3 , a polypropylene with a melt index of 1100g / 10min, a mass percentage of 90%, and a density of 1.05g / cm 3 , polystyrene with a melt index of 25g / 10min and a mass percentage of 10% is placed in a high-speed mixer and mixed evenly at high speed, then added to a screw extruder to melt and extrude, and then enters the melt blown through the material path and metering pump Die head, the melt meets high-speed hot air at the outlet of the melt-blown die head, and is drawn and refined under the action of high-speed hot air, and then deposited on the net curtain to form polystyrene / polypropylene blended melt-blown oil-absorbing material . After testing, the crystallinity of the oil-absorbing material is 18%, the oil absorption ratio reaches 9.4g / g, the absorption saturation can be reached within 6 minutes, and the oil retention rate is 87.8%.

Embodiment 3

[0017] Set the density to 0.91g / cm 3 , the melt index is 1100g / 10min, the mass percentage is 85% polypropylene and the density is 1.06g / cm 3 , polystyrene with a melt index of 25g / 10min and a mass percentage of 15% is placed in a high-speed mixer and mixed evenly at high speed, then added to a screw extruder to melt and extrude, and then enters the melt blown through the material path and metering pump Die head, the melt meets high-speed hot air at the outlet of the melt-blown die head, and is drawn and refined under the action of high-speed hot air, and then deposited on the net curtain to form polystyrene / polypropylene blended melt-blown oil-absorbing material . After testing, the crystallinity of the oil-absorbing material is 17%, the oil-absorbing ratio reaches 11.3g / g, the absorption saturation can be reached within 5 minutes, and the oil-retention rate is 92.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com