A room temperature wide temperature range giant negative thermal expansion material and its preparation method

A technology of negative thermal expansion material and wide temperature range, applied in the field of negative thermal expansion material, can solve the problem that it is difficult to effectively widen the phase change temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

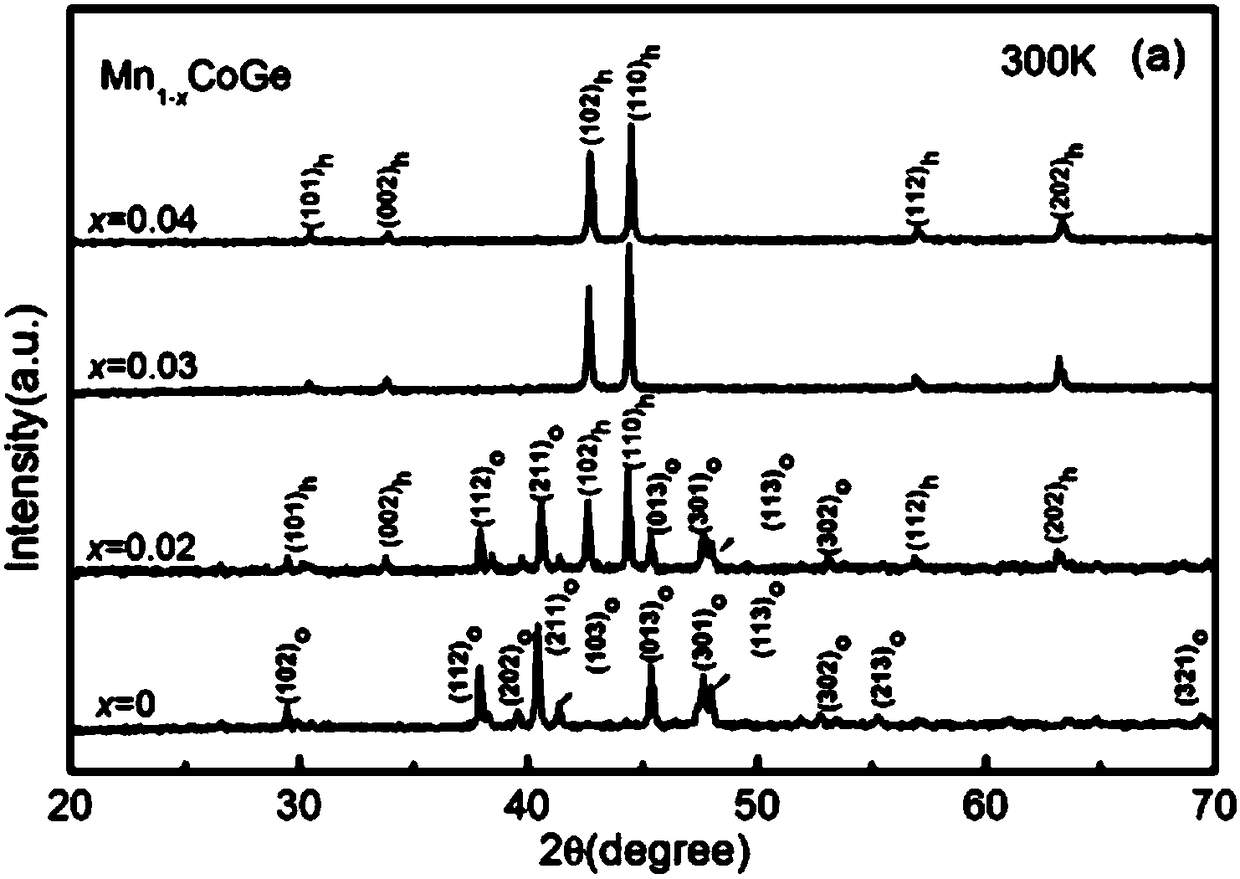

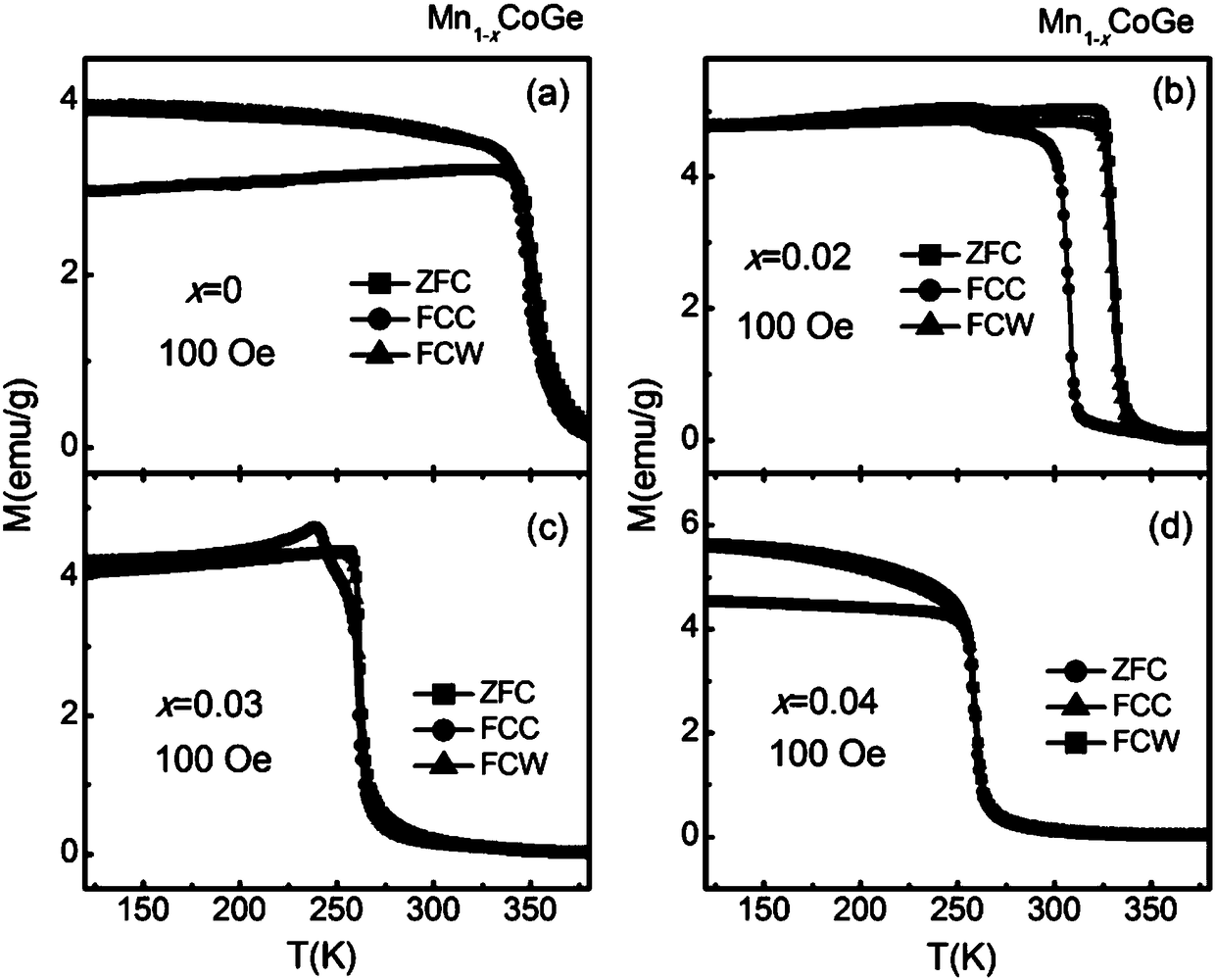

Method used

Image

Examples

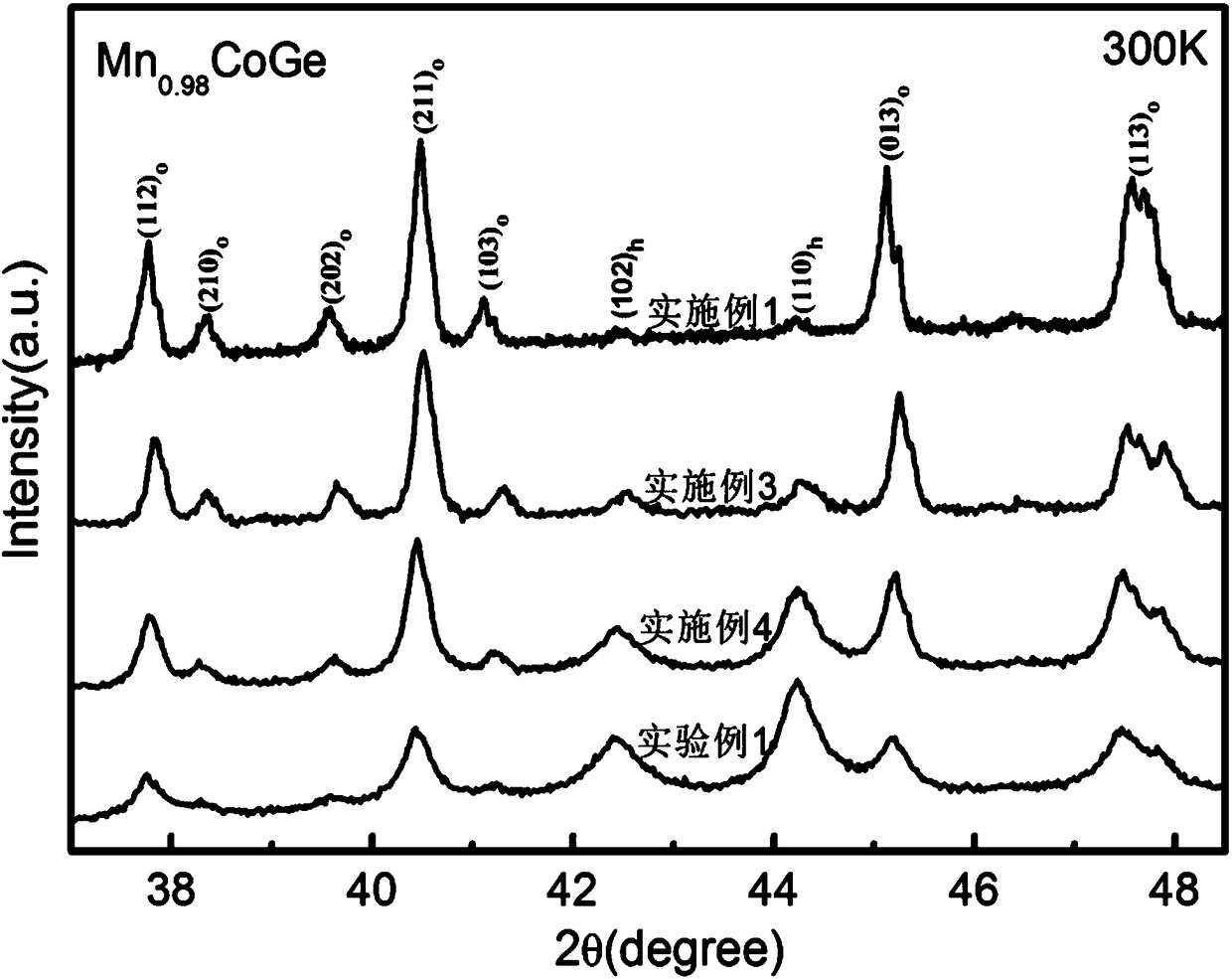

Embodiment 1

[0035] The preparation method of the above-mentioned huge negative thermal expansion material in a wide temperature range at room temperature proposed by the present invention, mixes germanium powder, manganese powder and cobalt powder, grinds, compresses tablets, places in a quartz tube, and evacuates to 1.33×10 -3 Pa, and then sintered after the hydrogen-oxygen flame sealed the tube, the sintering temperature was 925°C, and the sintering time was 3 days, cooled to room temperature with the furnace, taken out, ground, pressed into tablets, placed in a quartz tube, and evacuated to 1.33×10 -3 Pa, and then sintered after the hydrogen-oxygen flame sealed the tube, the sintering temperature was 925°C, the sintering time was 3 days, and the block Mn was obtained by cooling to room temperature with the furnace. 0.98 CoGe; Mn 0.98 CoGe was placed in a quartz tube and evacuated to 1.33×10 -3 Pa, then oxyhydrogen flame seal the tube; will contain Mn 0.98 Place the CoGe quartz tube i...

Embodiment 2

[0037] The preparation method of the above-mentioned huge negative thermal expansion material in a wide temperature range at room temperature proposed by the present invention, mixes germanium powder, manganese powder and cobalt powder, grinds, compresses tablets, places in a quartz tube, and evacuates to 1.33×10 -3 Pa, and then sintered after the hydrogen-oxygen flame sealed the tube, the sintering temperature was 925°C, and the sintering time was 3 days, cooled to room temperature with the furnace, taken out, ground, pressed into tablets, placed in a quartz tube, and evacuated to 1.33×10 -3 Pa, and then sintered after the hydrogen-oxygen flame sealed the tube, the sintering temperature was 925°C, the sintering time was 3 days, and the block Mn was obtained by cooling to room temperature with the furnace. 0.98 CoGe; Mn 0.98 CoGe was placed in a quartz tube and evacuated to 1.33×10 -3 Pa, then oxyhydrogen flame seal the tube; will contain Mn 0.98 Place the CoGe quartz tube i...

Embodiment 3

[0039] The preparation method of the above-mentioned huge negative thermal expansion material in a wide temperature range at room temperature proposed by the present invention, mixes germanium powder, manganese powder and cobalt powder, grinds, compresses tablets, places in a quartz tube, and evacuates to 1.33×10 -3 Pa, and then sintered after the hydrogen-oxygen flame sealed the tube, the sintering temperature was 925°C, and the sintering time was 3 days, cooled to room temperature with the furnace, taken out, ground, pressed into tablets, placed in a quartz tube, and evacuated to 1.33×10 -3 Pa, and then sintered after the hydrogen-oxygen flame sealed the tube, the sintering temperature was 925°C, the sintering time was 3 days, and the block Mn was obtained by cooling to room temperature with the furnace. 0.98 CoGe; the bulk Mn 0.98 CoGe was ground in a mortar to obtain powdery Mn 0.98 CoGe; the powdered Mn 0.98 After mixing CoGe, grinding balls, and absolute ethanol at a w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com