Environment-friendly heat insulation and corrosion resistant paint and making method thereof

A corrosion-resistant and coating technology, applied in the fields of new materials and environmental protection and energy saving, can solve the problems of low energy consumption and environmental protection, aging resistance, heat resistance and poor heat insulation performance of buildings, and achieve simple and convenient construction and fire resistance Excellent performance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

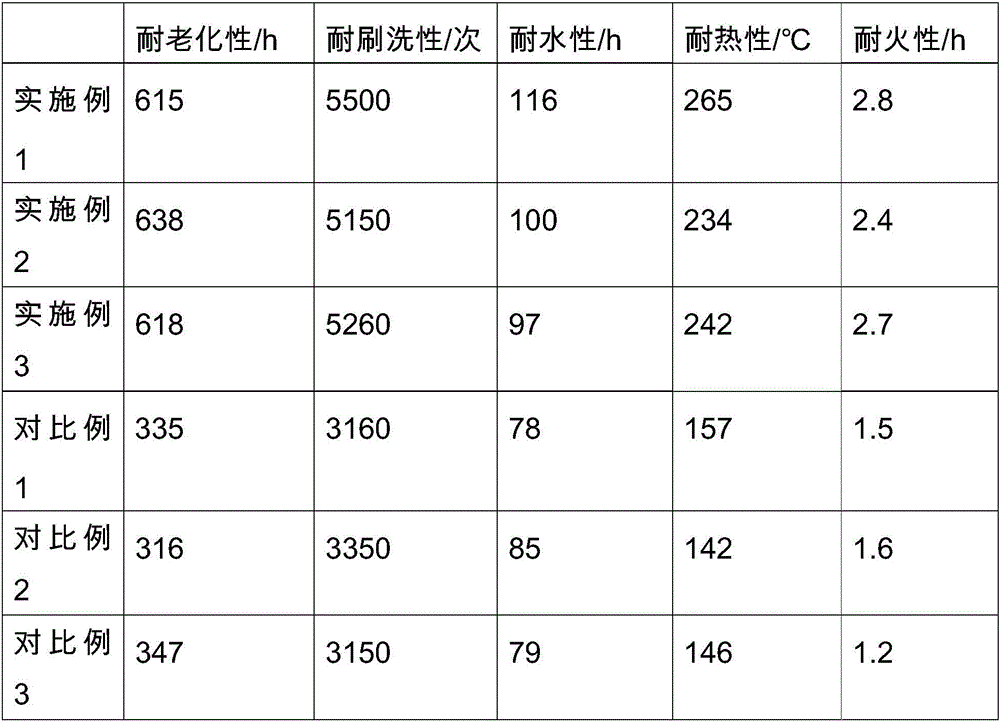

Examples

Embodiment 1

[0018] An environmentally friendly heat-insulating and corrosion-resistant coating, comprising the following components by weight: 150 parts by weight of water, 5 parts by weight of monoglyceride stearate, 3 parts by weight of tributyl phosphate, 15 parts by weight of propylene oxide, and 10 parts by weight of styrene 20 parts by weight of titanium dioxide, 50 parts by weight of silicon acrylic emulsion, 30 parts by weight of elastic emulsion, 5 parts by weight of isocyanate, 10 parts by weight of hydroxyethyl cellulose, 5 parts by weight of organic silicon, 10 parts by weight of amine resin, decabromodiphenyl 10 parts by weight of ethane, 10 parts by weight of tetraerythyl alcohol and 10 parts by weight of polyurethane.

Embodiment 2

[0020] An environmentally friendly heat-insulating and corrosion-resistant coating, comprising the following components in parts by weight: 250 parts by weight of water, 8 parts by weight of monoglyceride stearate, 7 parts by weight of tributyl phosphate, 20 parts by weight of propylene oxide, and 15 parts by weight of styrene parts, 35 parts by weight of titanium dioxide, 55 parts by weight of silicon acrylic emulsion, 40 parts by weight of elastic emulsion, 10 parts by weight of isocyanate, 15 parts by weight of hydroxyethyl cellulose, 10 parts by weight of organic silicon, 25 parts by weight of amine resin, decabromodiphenyl 20 parts by weight of ethane, 13 parts by weight of tetraerythyl alcohol.

Embodiment 3

[0022] An environmentally friendly heat-insulating and corrosion-resistant coating, comprising the following components by weight: 350 parts by weight of water, 10 parts by weight of monoglyceride stearate, 10 parts by weight of tributyl phosphate, 25 parts by weight of propylene oxide, 25 parts by weight of styrene Parts by weight, 55 parts by weight of titanium dioxide, 80 parts by weight of silicon acrylic emulsion, 60 parts by weight of elastic emulsion, 15 parts by weight of isocyanate, 20 parts by weight of hydroxyethyl cellulose, 15 parts by weight of organic silicon, 35 parts by weight of amine resin, 30 parts by weight of ethyl phenylene, 25 parts by weight of tetraerythyl alcohol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com