Preparation method and application of montmorillonite-graphene composite powder

A graphene composite and montmorillonite technology, applied in the field of preparation of montmorillonite-graphene composite powder, can solve the problems such as graphene and montmorillonite are not easily mixed with each other uniformly, graphene yield is low, and the process is complicated. , to achieve the effect of reducing binding force, high yield and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In the application of the montmorillonite-graphene composite powder in the embodiment of the present invention, the montmorillonite-graphene composite powder is used as a filler to prepare a polymer composite material, for example, the montmorillonite-graphene composite can be The powder is used to prepare montmorillonite-graphene / epoxy resin composite material, and the preparation method comprises the following steps: dispersing a certain amount of organically modified montmorillonite-graphene composite powder in a solvent, and Add epoxy resin and mix it evenly, then remove the solvent, add curing agent and accelerator to continue stirring and mixing, pour after removing the air bubbles in the mixture, and finally obtain montmorillonite-graphene / epoxy resin composite after curing Material. Certainly, the montmorillonite-graphene composite powder in the embodiment of the present invention can also be applied in the preparation process of other polymer composite material...

Embodiment 1

[0040] The preparation method of embodiment 1 of the present invention montmorillonite-graphene composite powder comprises the following steps:

[0041] Firstly, dissolve 0.4 g of crystal violet in 100 ml of deionized water, ultrasonicate for about 1 min to fully dissolve the crystal violet, then add 1 g of montmorillonite, stir at 25°C for at least 4 hours with a magnetic stirrer, then centrifuge and wash. Organic montmorillonite adsorbing crystal violet was obtained after drying at 60°C.

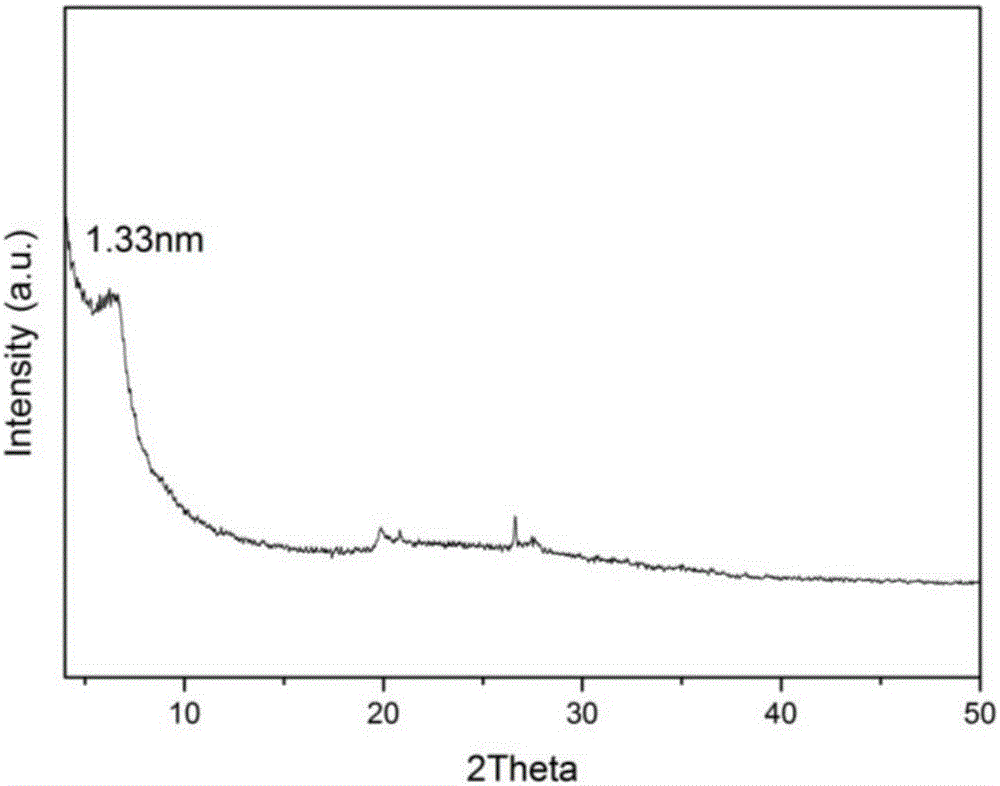

[0042]The above-mentioned montmorillonite adsorbed crystal violet was calcined at 600°C for 3 hours under the protection of nitrogen, and the crystal violet between the montmorillonite sheets was carbonized to form graphene, thereby obtaining a composite of montmorillonite-graphene interpenetrating Powder. figure 2 It is the XRD pattern of the montmorillonite-graphene composite powder of Example 1 obtained after the montmorillonite with interlayer adsorption of crystal violet is calcined...

Embodiment 2

[0056] The preparation method of embodiment 2 of the present invention montmorillonite-graphene composite powder comprises the following steps:

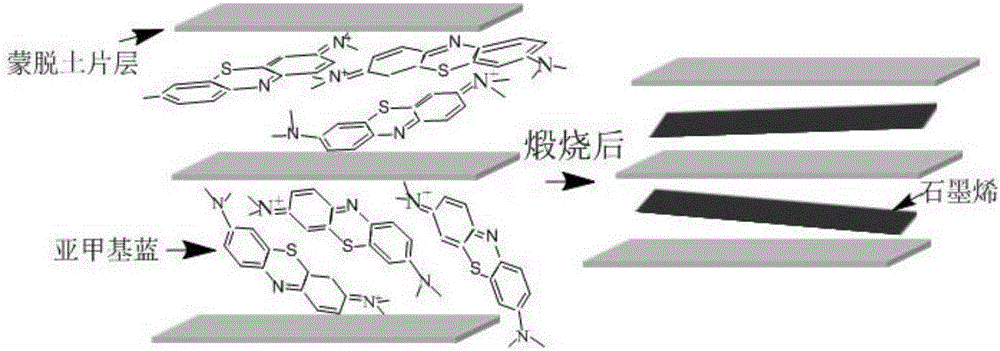

[0057] First, dissolve 0.8 g of methylene blue in 100 ml of deionized water, ultrasonically dissolve the methylene blue for about 1 min, then add 1 g of montmorillonite, stir at 25°C for at least 4 hours with a magnetic stirrer, and then centrifuge and wash, and place at 60°C The organic montmorillonite adsorbed methylene blue was obtained after drying under high temperature.

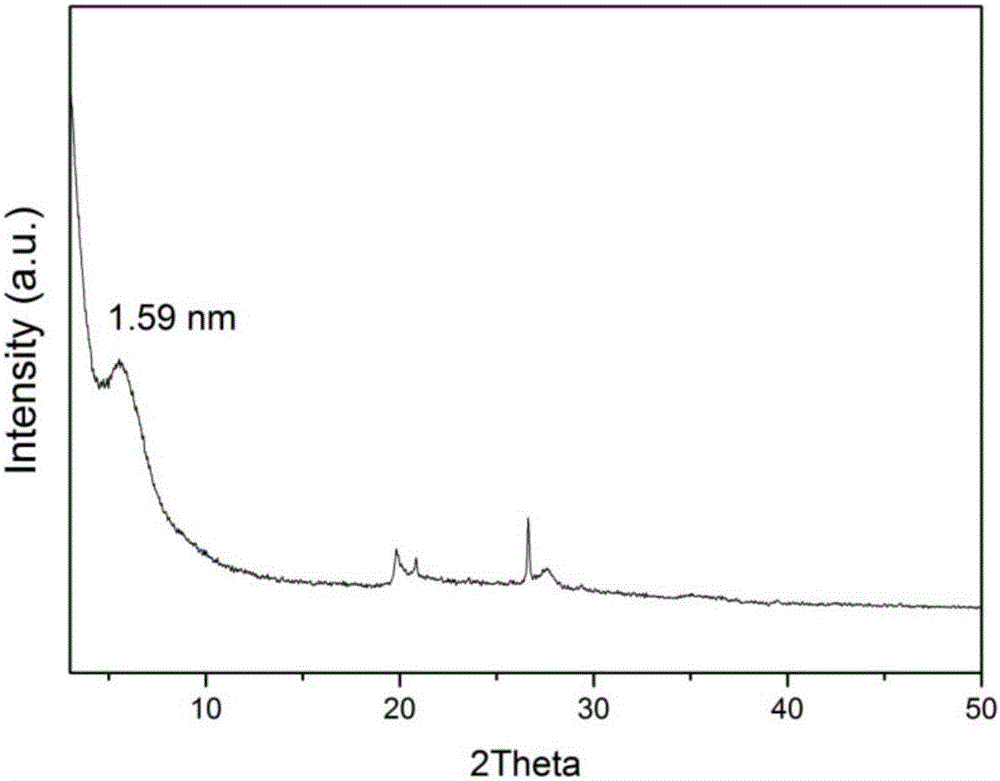

[0058] The montmorillonite adsorbed methylene blue was calcined at 600°C for 3 hours under the protection of argon, and the methylene blue between the montmorillonite sheets was carbonized to form graphene, thereby obtaining a composite powder of montmorillonite-graphene interpenetrating . image 3 It is the XRD pattern of the montmorillonite-graphene composite powder obtained after calcination of the montmorillonite interlayer adsorbing methylene blue in Exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com