A kind of preparation method of the nano-boehmite filler of surface graft corrosion inhibitor

A technology of nano-boehmite and surface grafting, which is applied in the field of preparation of nano-boehmite fillers, can solve problems such as difficulty in controlling the stability of the reaction process, agglomeration of products and final products, and difficulty in removing inorganic oxides, so as to improve the comprehensive Anti-corrosion performance, improved corrosion resistance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

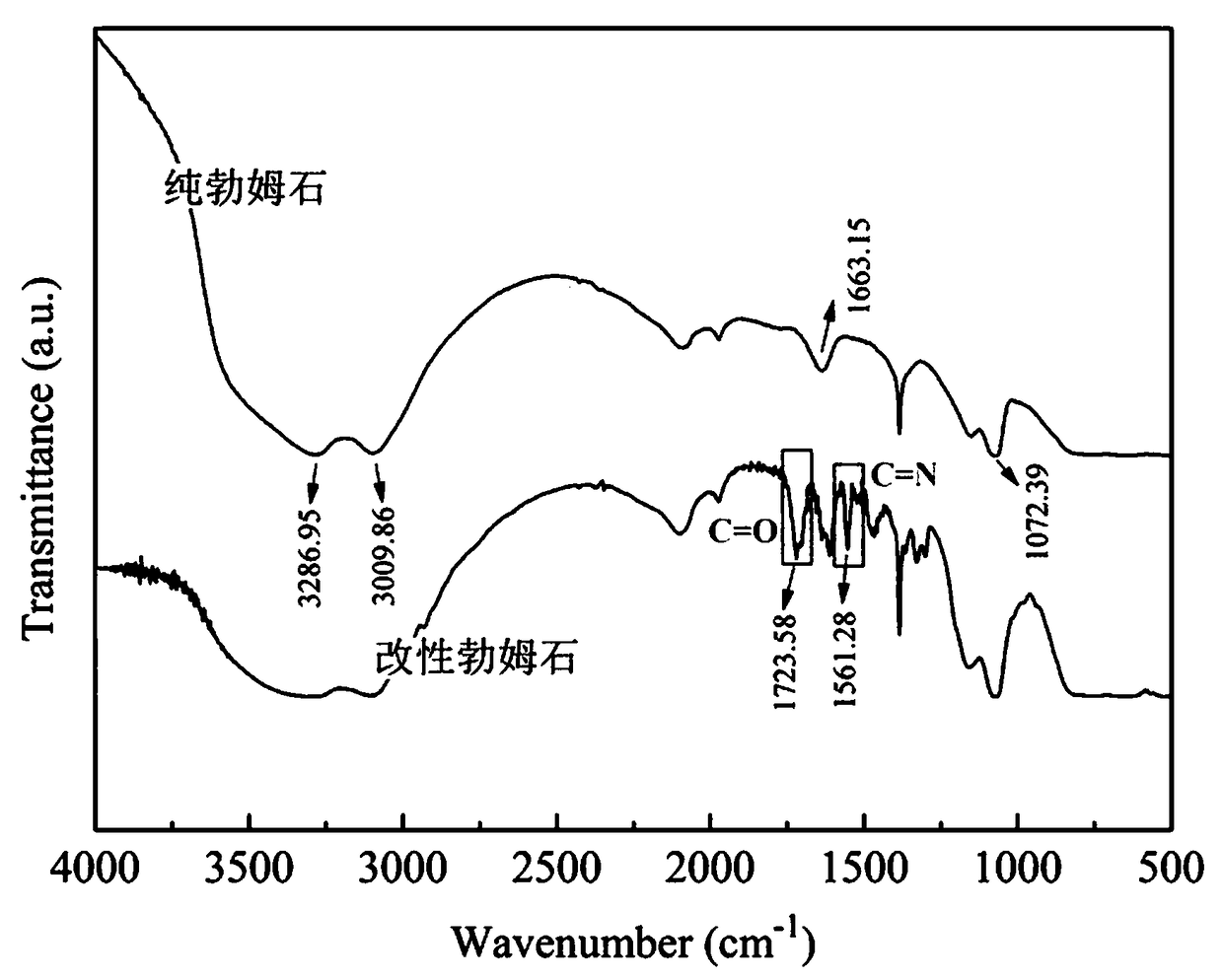

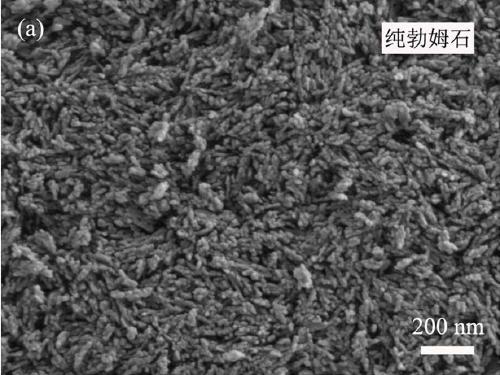

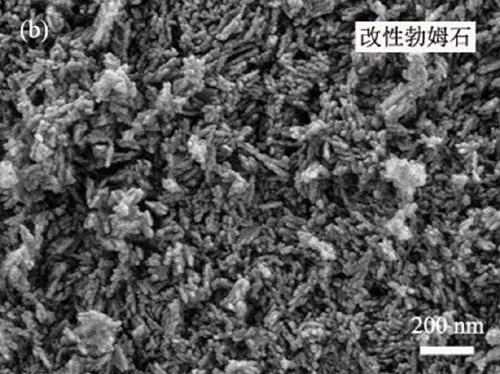

[0028] A kind of preparation method of the nano boehmite filler of surface graft corrosion inhibitor, comprises the following steps:

[0029] Step 1: After drying the corrosion inhibitor, slowly add it into an anhydrous solvent under the condition of ultrasonic dispersion, and continue ultrasonic dispersion for 30 minutes at room temperature to obtain a corrosion inhibitor solution; the corrosion inhibitor is 5-amino-1 , 3,4-thiadiazole-2-thiol, 1,2,3-benzotriazole, mercaptobenzothiazole, tolyltriazole and other metal corrosion inhibitors; the anhydrous solvent is toluene or xylene and other benzene organic solvents; the drying process adopts a constant temperature drying method, specifically, the corrosion inhibitor is placed in a constant temperature drying box and dried to a constant weight, and the drying temperature is 80 ° C; the anhydrous solvent dewatering process uses Molecular sieve soaking method, specifically, soak the activated 3A molecular sieve in the solvent to...

Embodiment 1

[0034] Step 1: Weigh 19.6g of dried 5-amino-1,3,4-thiadiazole-2-thiol (AMT), and slowly add it into a beaker containing 2000mL of anhydrous xylene under the condition of ultrasonic dispersion AMT solution was obtained after continuous ultrasonic dispersion at room temperature for 30 minutes;

[0035] Step 2: Transfer the AMT solution into a three-necked flask, put 20mL of triethylamine catalyst, 18.2g of KBM-5103 silane coupling agent (the molar ratio of AMT to KBM-5103 is 2:1), and 0.2g of hydroquinone polymerization inhibitor in Slowly add to the AMT solution under the condition of 80°C temperature and high-speed stirring and dispersion, and continue to stir and react at 80°C for 6 hours;

[0036] Step 3: Weigh 18.2g of dried boehmite filler, slowly add it into a beaker containing 500mL of anhydrous xylene under the condition of ultrasonic dispersion, and obtain nano-boehmite filler suspension after continuous ultrasonic dispersion at room temperature for 30 minutes liquid;...

Embodiment 2

[0041] Step 1: Weigh 19.6 g of dried AMT, slowly add it into a beaker containing 2000 mL of anhydrous xylene under ultrasonic dispersion conditions, and obtain an AMT solution after continuous ultrasonic dispersion at room temperature for 30 minutes.

[0042] Step 2: Transfer the AMT solution into a three-necked flask, put 20mL of triethylamine catalyst, 36.5g of KBM-5103 silane coupling agent (the molar ratio of AMT to KBM-5103 is 1:1), and 0.2g of hydroquinone polymerization inhibitor in Slowly add into the AMT solution under the condition of 80°C temperature and high-speed stirring and dispersion, and continue to stir and react at 80°C for 6 hours.

[0043] Step 3: Weigh 36.5g of dried boehmite filler, slowly add it into a beaker containing 500mL of anhydrous xylene under the condition of ultrasonic dispersion, and obtain nano-boehmite filler suspension after continuous ultrasonic dispersion at room temperature for 30 minutes liquid.

[0044] Step 4: Add the nano-boehmite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com