Making method of halogen-free flame retardant copper clad laminate

A production method and flame-retardant technology, which are applied in chemical instruments and methods, adhesive types, epoxy resin adhesives, etc., can solve problems such as low cost, human health damage, and environmental pollution, and achieve good electrical performance, high Effect of Tg value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

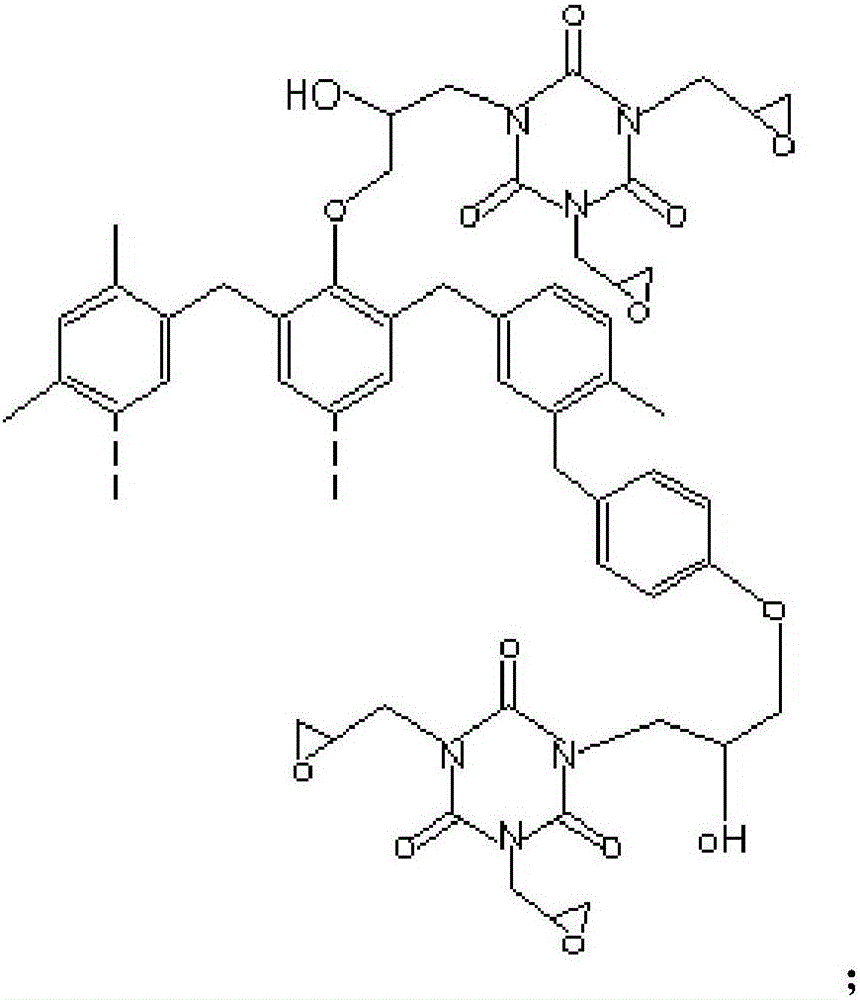

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Preparation of Halogen-free Flame Retardant Copper Clad Laminate

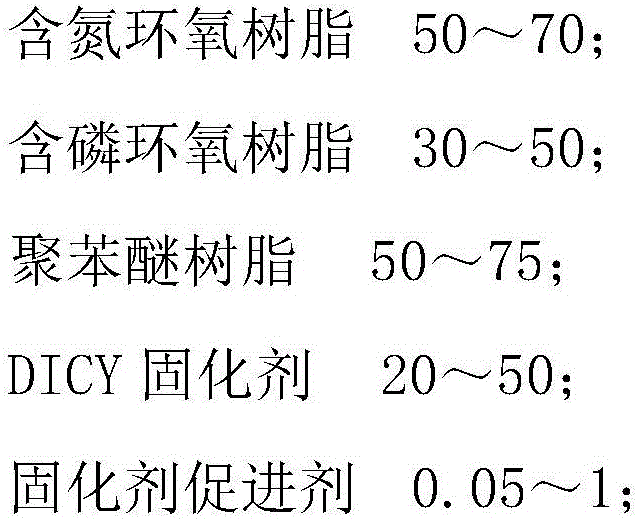

[0032] 1) Modulation of insulating layer glue formula (parts by weight):

[0033]

[0034] The components were fully mixed for 8 hours, and the gelation time of the glue was 255 seconds.

[0035] 2) Gluing: Glue the glass fiber cloth and dry it in a vertical gluing machine to make a prepreg. The gluing speed is 20m / min. Control parameters: gelation time is 120S, resin content is 40%, fluidity 25%;

[0036] 3) Lamination and pressing: According to the product thickness requirements, control the pressing parameters:

[0037] Vacuum degree: 0.005Mpa;

[0038] Pressure: 500PSI;

[0039] Heating rate: 2°C / min;

[0040] Hot plate temperature: 120~230℃;

[0041] Pressing time: 150min;

[0042] Among them, when the temperature of the hot plate is 230 degrees, the corresponding high pressure is 500PSI, and the operation is about 55min at this time;

[0043] Finally, it passes the board appear...

Embodiment 2

[0044] Example 2 Preparation of Halogen-Free Flame-Retardant Copper Clad Laminate

[0045] 1) Modulation of insulating layer glue formula (parts by weight):

[0046]

[0047]

[0048] The components were fully mixed for 8 hours, and the gelation time of the glue was 255 seconds.

[0049] 2) Gluing: Glue the glass fiber cloth and dry it in a vertical gluing machine to make a prepreg. The gluing speed is 22m / min. Control parameters: gelation time is 120S, resin content is 45%, fluidity 20%;

[0050] 3) Lamination and pressing: According to the product thickness requirements, control the pressing parameters:

[0051] Vacuum degree: 0.005Mpa;

[0052] Pressure: 500PSI;

[0053] Heating rate: 2°C / min;

[0054] Hot plate temperature: 120~230℃;

[0055] Pressing time: 150min;

[0056] Among them, when the temperature of the hot plate is 230 degrees, the corresponding high pressure is 500PSI, and the operation is about 55min at this time;

[0057] Finally, it passes the ...

Embodiment 3

[0058] Example 3 Preparation of Halogen-free Flame Retardant Copper Clad Laminate

[0059] 1) Modulation of insulating layer glue formula (parts by weight):

[0060]

[0061] The components were fully mixed for 8 hours, and the gelation time of the glue was 255 seconds.

[0062] 2) Gluing: Glue the glass fiber cloth and dry it in a vertical gluing machine to make a prepreg. The gluing speed is 22m / min. Control parameters: gelation time is 120S, resin content is 45%, fluidity 20%;

[0063] 3) Lamination and pressing: According to the product thickness requirements, control the pressing parameters:

[0064] Vacuum degree: 0.01Mpa;

[0065] Pressure: 550PSI;

[0066] Heating rate: 2°C / min;

[0067] Hot plate temperature: 120~230℃;

[0068] Pressing time: 150min;

[0069] Among them, when the temperature of the hot plate is 230 degrees, the corresponding high pressure is 550PSI, and it runs for about 60 minutes at this time;

[0070] Finally, it passes the board appeara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com