Titanium-modified high-chromium cast iron type self-protection surfacing flux-cored wire and preparation method thereof

A high-chromium cast iron, self-protection technology, applied in welding equipment, welding medium, manufacturing tools, etc., to achieve the effect of simple and reliable preparation method, high deposition efficiency, and high degree of alloy homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

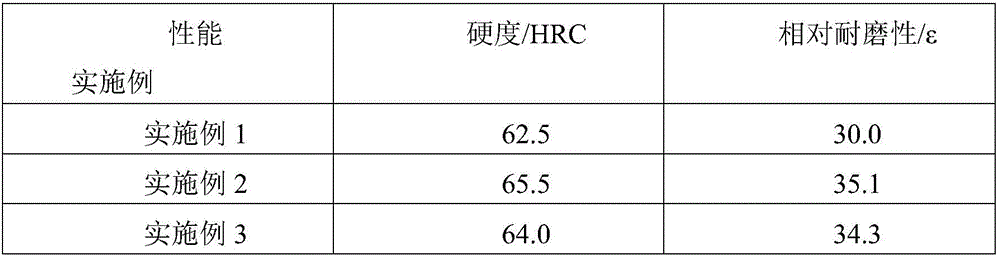

Embodiment 1

[0034]A titanium-modified high-chromium cast iron type self-shielding surfacing flux-cored welding wire, including a low-carbon steel strip and a flux core, the flux core is filled in the steel strip, and the composition of the flux core is prepared according to the following quality: 60g of 80-mesh high-carbon chromium Iron, 26g of 80 mesh titanium iron, 0.5g of 60 mesh graphite, 1g of 200 mesh graphite, 3g of 60 mesh aluminum magnesium alloy, 1g of 200 mesh aluminum magnesium alloy, 5g of 60 mesh silicon manganese alloy, 2g of 200 mesh silicon Manganese alloy, 1.5g of 80 mesh iron powder. Put the various powders taken into the powder mixer, mix for 40 minutes, then add the mixed powder into the U-shaped 21×0.5mm H08A carbon steel belt groove, and the filling rate is 50%. Then close the U-shaped groove so that the powder is wrapped therein. Then make it pass through one or more of the wire drawing dies with diameters of 4.2mm, 3.8mm, 3.5mm, 3.2mm, and 2.8mm, draw and reduce ...

Embodiment 2

[0036] A titanium-modified high-chromium cast iron type self-shielding surfacing flux-cored welding wire, including a low-carbon steel strip and a flux core, the flux core is filled in the steel strip, and the composition of the flux core is prepared according to the following quality: 55g of 80-mesh high-carbon chromium Iron, 32g of 80 mesh titanium iron, 1g of 60 mesh graphite, 2g of 200 mesh graphite, 1g of 60 mesh aluminum magnesium alloy, 2g of 200 mesh aluminum magnesium alloy, 2g of 60 mesh silicon manganese alloy, 3g of 200 mesh silicon manganese Alloy, 2g of 80 mesh iron powder. The various powders taken are put into the powder mixer, mixed for 40 minutes, and then the mixed powder is added into the U-shaped 21×0.5mm H08A carbon steel belt groove, and the filling rate is 55%. Then close the U-shaped groove so that the powder is wrapped therein. Then make it pass through one or more of the wire drawing dies with diameters of 4.2mm, 3.8mm, 3.5mm, 3.2mm, and 2.8mm, draw...

Embodiment 3

[0038] A titanium-modified high-chromium cast iron type self-shielding surfacing flux-cored welding wire, including a low-carbon steel strip and a flux core, the flux core is filled in the steel strip, and the composition of the flux core is prepared according to the following quality: 58g of 80-mesh high-carbon chromium Iron, 28g of 80-mesh ferrotitanium, 0.8g of 60-mesh graphite, 1.2g of 200-mesh graphite, 2g of 60-mesh aluminum-magnesium alloy, 1.5g of 200-mesh aluminum-magnesium alloy, 3g of 60-mesh silicon-manganese alloy, 2.5g of 200 mesh silicon manganese alloy, 3g of 80 mesh iron powder. Put the various powders taken into the powder mixer, mix for 40 minutes, then add the mixed powder into the U-shaped 21×0.5mm H08A carbon steel belt groove, and the filling rate is 53%. Then close the U-shaped groove so that the powder is wrapped therein. Then make it pass through one or more of the wire drawing dies with diameters of 4.2mm, 3.8mm, 3.5mm, 3.2mm, and 2.8mm, draw and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com