High-energy-rate pulse impact hydraulic-forming method

A pulsating impact and hydroforming technology, applied in the field of high-speed material forming, can solve the problems of unmentioned cyclic pulsating impact, cracking, wrinkling, etc., and achieve the effect of reducing equipment requirements, shortening forming time, and improving forming limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

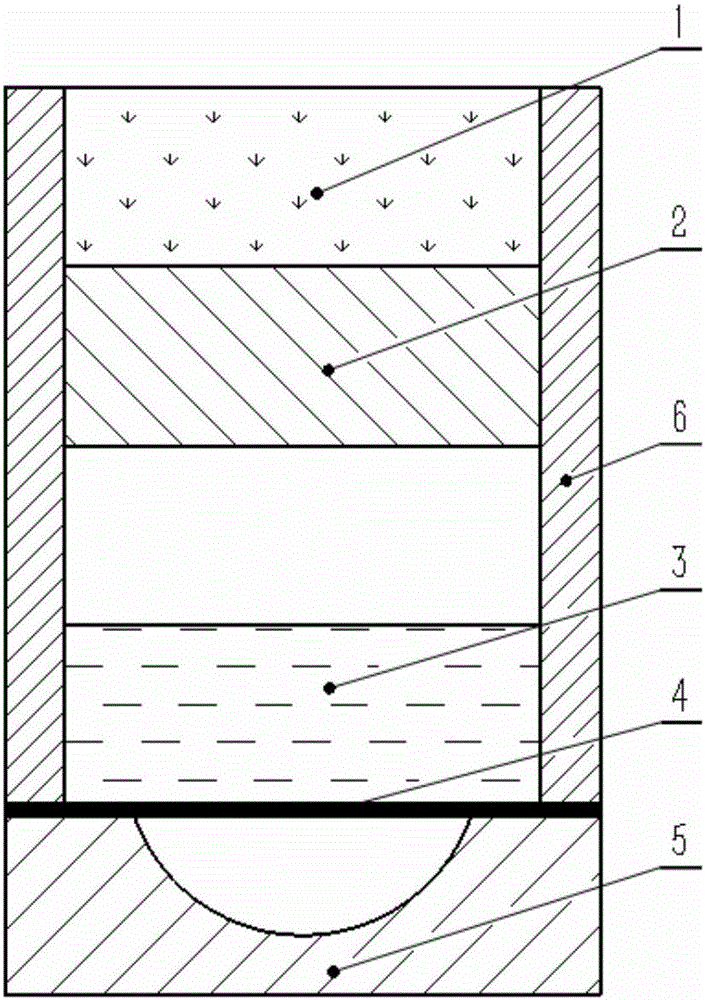

[0039] This embodiment takes a typical plate part as an example, combining Figure 2-5 Specific embodiments of the present invention will be described.

[0040] (1) In the parameter setting stage, according to the requirements of materials and parts, the impact frequency, impact energy, and liquid filling volume are formulated; for example, for a metal plate with a thickness of 1mm and a yield strength of 300MPa and an elongation rate of 50%, three impacts are used, each impact energy is 16KJ, and the impact velocity 20m / s, the cavity volume of the required forming part is 2L, the actual working medium is 3L, and the blank holder force is 150t.

[0041] (2) The feeding stage, such as figure 2 , the process is: the plate 4 is placed in the plate mold 5 and positioned;

[0042] (3) Liquid filling stage, such as figure 2 , the process is: according to the command of the control system, filling the liquid medium 3 with a preset volume;

[0043] (4) The first impact stroke, s...

Embodiment 2

[0048] The following takes a typical pipe part as an example, combined with Figure 6-7 The present invention is described in detail.

[0049] Using the above-mentioned pulsating impact hydroforming method, the forming process of the hard-to-form material pipe is the same as the forming process of the plate part in Example 1, wherein the pipe 7 has the same effect as the plate 4, and the pipe mold 8 has the same effect as the plate mold 5.

[0050] In Example 1-2, the parts were obtained by progressive high-energy-rate pulsating impact hydroforming that reasonably distributed the deformation to multiple passes. After testing, the parts did not appear to be cracked or wrinkled, which shows that the method of the present invention can solve the problem very well. Occurrence of workmanship defects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com