Device for quickly winding coverage strips

A fast, compacting block technology, applied in the direction of sewing tools and other directions, can solve the problems of loose wrapping, different winding widths, time-consuming and labor-intensive, etc., and achieve the effect of not easy to loosen and fast forming time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

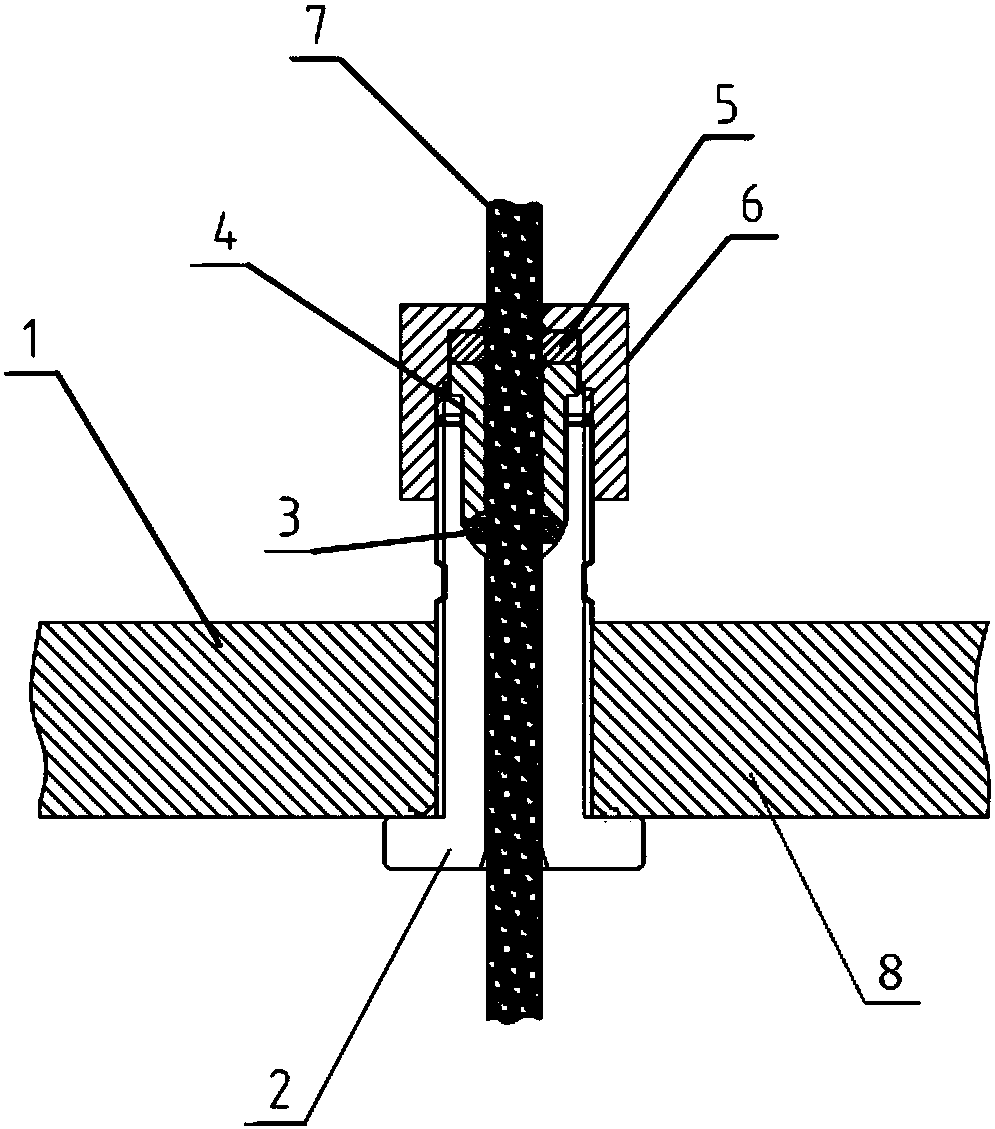

[0018] Example: see figure 1 , a device for wrapping strips quickly, including a rotating head 2 and an end cover 6, the rotating head 2 and the end cover 6 are provided with wire holes, and the left and right sides of the rotating head 2 are provided with wrapping strip inlets , the wrapping strip is divided into a left wrapping strip 1 and a right wrapping strip 8, and the front end surface of the rotary head 2 is provided with a U-shaped hole groove in section, and a pressing fast 4 is arranged in the hole groove, and the fastening fast 4 The front end is located at the arc portion of the bottom of the hole, and a compression ring 3 is provided between the front end surface of the compression fast 4 and the bottom surface of the hole, and the middle part of the compression fast 4 is provided with a line along its length direction. For the through hole corresponding to the hole, the compression fast 4 makes the compression ring 3 squeeze tightly to the wire core 7, and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com