Automobile grill hot stamping process

A technology of hot stamping and hot stamping film, which is applied in printing, printing devices, copying/marking methods, etc. It can solve the problems of huge height difference of hot stamping surface, long overall size of grid, and inability to realize hot stamping. Low energy consumption, short forming time, and the effect of improving the quality of interior and exterior decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

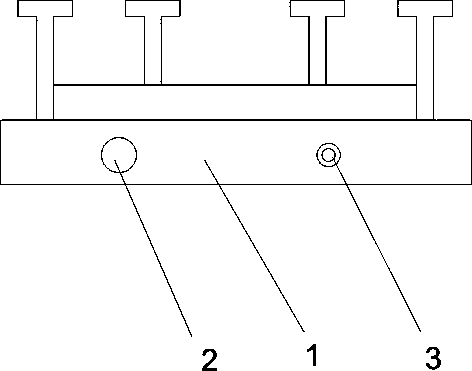

[0027] In order to make the content of the present invention more easily and clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

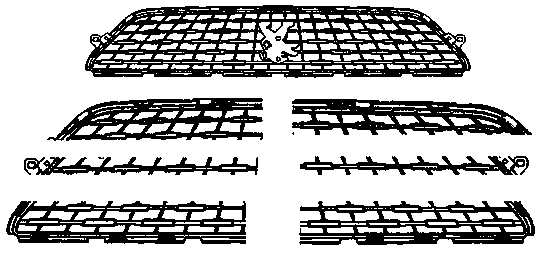

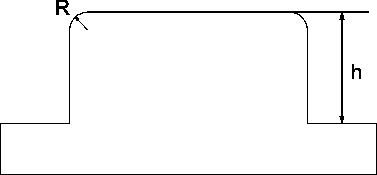

[0028] Such as Figure 1 to Figure 4 As shown, the hot stamping film of the automobile grille hot stamping process in the embodiment of the present invention is to coat a layer of metal on the film sheet, and realize hot stamping through the transferable process coating of the carrier coating; the hot stamping film includes the following parts:

[0029] The carrier, also known as the base film layer or the base layer, has different thickness specifications and supports other layers. Its material is PET polyester film, which has the advantages of easy degradation, high temperature resistance, good unidirectional stretchability, and not easy to break;

[0030] Peeling layer, also known as separation layer, hot stamping needs to be quickly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com