Goose fattening feed containing cassava leaves, preparing method and using method of goose fattening feed

A technology for cassava leaves and fattening geese, which is applied in animal feed, animal feed, application, etc., can solve the problems of the surge in the import of feed grains, the increase in the price of feed grains, and the increase in breeding costs, so as to increase the fiber content of the diet and reduce the Feed grains, the effect of reducing the amount of protein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

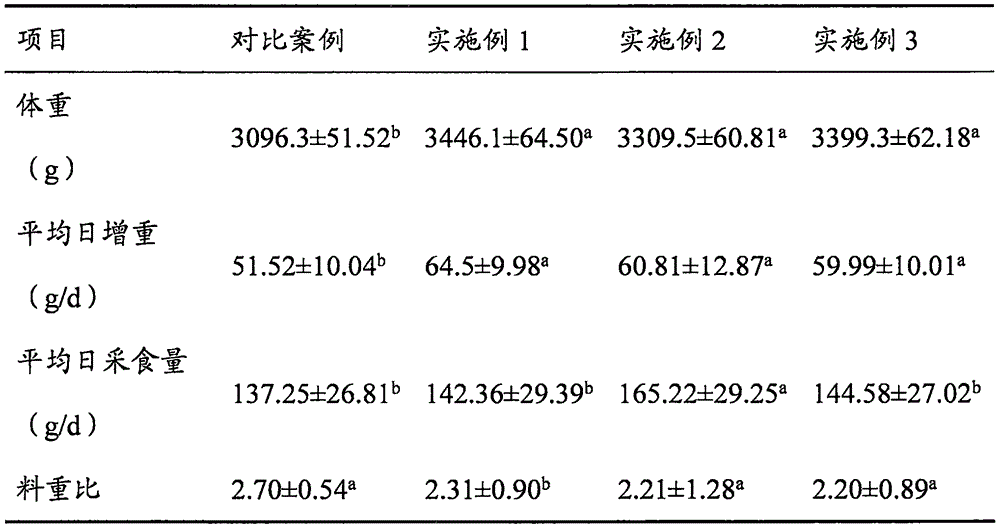

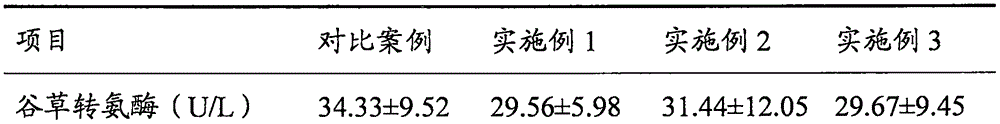

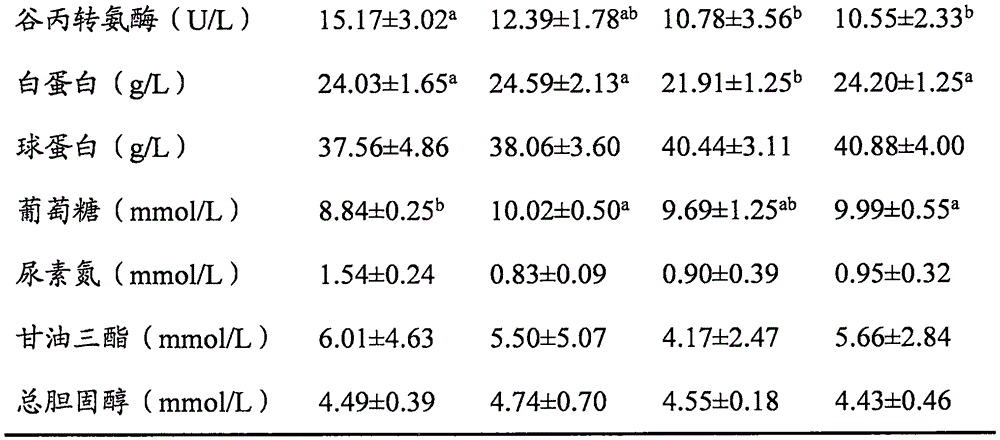

Examples

Embodiment 1

[0030] Embodiment 1 contains the fattening goose feed of cassava leaf, and its raw material is by mass percentage by the cassava leaf of 5%, the corn of 58.5%, the soybean meal of 21%, the bran of 7.5%, the vegetable oil of 1.5%, the stone powder of 2%, 0.2% % dibasic calcium phosphate, 0.3% methionine, 4% goose premix composition, concretely implement according to the following steps:

[0031] Step 1, the cassava leaves are the leaves of Huanan No. 7 cassava grown to a plant height equal to 120cm, and the distance from the top of the plant is equivalent to 1 / 4 of the plant height, and the leaves are dried at a temperature of 35°C until the water content in the cassava leaves is equal to 25%, pulverized and passed through a 40-mesh sieve to obtain cassava leaf powder;

[0032] Step 2, respectively pulverizing corn, soybean meal, bran, fish meal and stone powder, and then passing through a 40-mesh sieve to obtain corn meal, soybean meal powder, bran powder, fish meal and stone ...

Embodiment 2

[0035] Embodiment 2 contains the fattening goose feed of cassava leaf, and its raw material is by mass percentage by the cassava leaf of 10%, the corn of 50.3%, the soybean meal of 20%, the bran of 7%, the vegetable oil of 4%, the fish meal of 3%, 1.5% % stone powder, 0.1% calcium hydrogen phosphate, 0.2% methionine, and 3.9% goose premix, specifically implemented according to the following steps:

[0036] Step 1, the cassava leaves are the leaves of Huanan No. 7 cassava grown to a plant height equal to 130cm, and the distance from the top of the plant is equivalent to 1 / 3 of the plant height, and the leaves are dried at a temperature of 36°C until the water content in the cassava leaves is equal to 23%, pulverized, and crossed a 40-mesh sieve to obtain cassava leaf powder;

[0037] Step 2, respectively pulverizing corn, soybean meal, bran, fish meal and stone powder, and then passing through a 40-mesh sieve to obtain corn meal, soybean meal powder, bran powder, fish meal and ...

Embodiment 3

[0040] Embodiment 3 contains the fattening goose feed of cassava leaf, and its raw material is made of 15% cassava leaf, 55.5% corn, 17.6% soybean meal, 5% bran, 0.5% vegetable oil, 1.5% fish meal, 1 % of stone powder, 0.5% of calcium hydrogen phosphate, 0.4% of methionine, and 3% of goose premix, specifically implemented according to the following steps:

[0041]Step 1, cassava leaves are the leaves of Huanan No. 7 cassava grown to a plant height equal to 120cm, and the distance from the top of the plant is equivalent to 1 / 3 of the plant height, and the leaves are dried at a temperature of 35°C until the water content in the cassava leaves is equal to 23%, pulverized, and crossed a 40-mesh sieve to obtain cassava leaf powder;

[0042] Step 2, respectively pulverizing corn, soybean meal, bran, fish meal and stone powder, and then passing through a 40-mesh sieve to obtain corn meal, soybean meal powder, bran powder, fish meal and stone powder;

[0043] Step 3, taking by weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com