High-voltage electrostatic protection shell fabric and manufacturing technology thereof

A high-voltage electrostatic and manufacturing process technology, which is applied in textiles and papermaking, fabric surface trimming, textiles, etc., can solve the problem of incomplete functions of high-voltage electrostatic protective fabrics, and achieve the effect of excellent test results and multiple functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

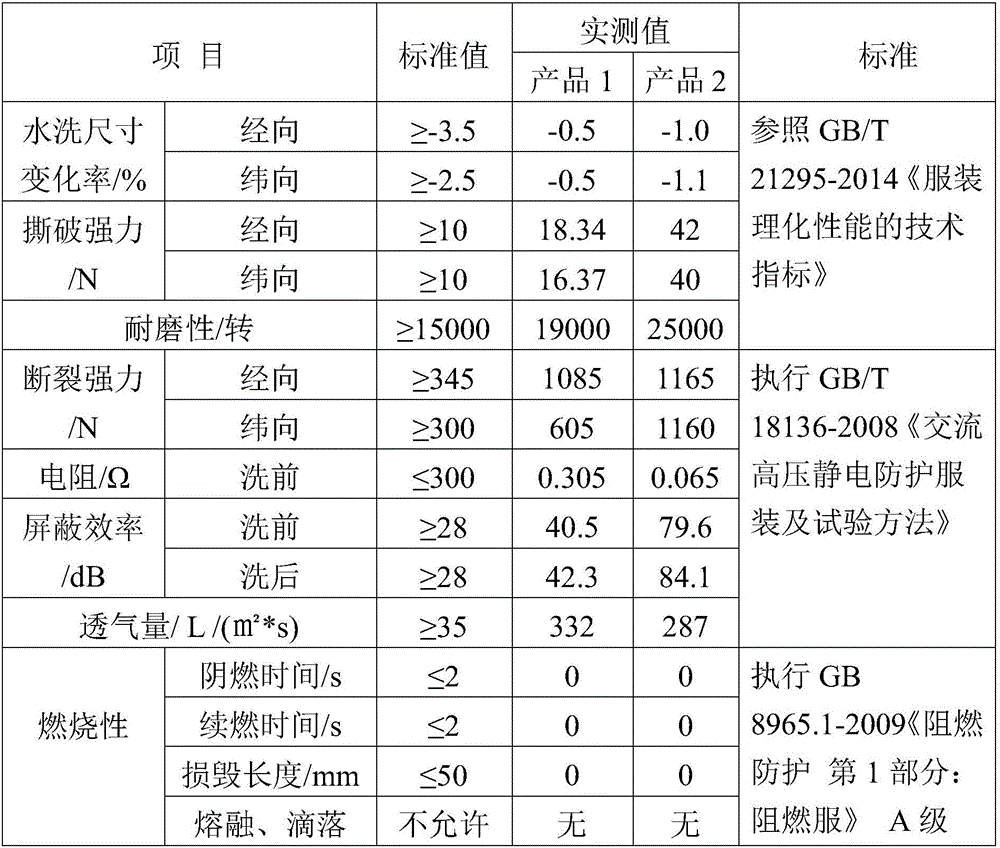

Examples

Embodiment 1

[0039] The high-voltage electrostatic protection fabric in this embodiment is formed by interweaving warp and weft yarns, and the warp and weft yarns are all blended yarns of metal fibers (stainless steel fibers), nylon fibers, aramid 1313 fibers and aramid 1414 fibers. The weight content of metal fiber in the blended yarn is 75%, the weight content of aramid fiber 1414 is 10%, the weight content of aramid fiber 1313 is 10%, and the weight content of nylon fiber is 5%. The linear density of the blended yarn was 28.1tex×2. The fabric structure is 1 / 1 plain weave, and the mass per unit area of gray cloth is 230g / m 2 .

[0040] The above-mentioned high-voltage electrostatic fabric adopts the following weaving process, and the steps are as follows:

[0041] (1) Spinning: Metal fiber, aramid 1313 fiber, aramid 1414 fiber and nylon fiber are used as raw materials, followed by cleaning→carding→drawing→roving→spinning→winding→doubling→twisting→steaming The yarn is made into a ble...

Embodiment 2

[0051] The high-voltage electrostatic protection fabric in this embodiment is formed by interweaving warp and weft yarns, and the warp and weft yarns are all blended yarns of metal fibers (stainless steel fibers), aramid 1313 fibers and aramid 1414 fibers. The metal fiber weight content in the blended yarn is 30%, the aramid fiber 1414 fiber weight content is 35%, and the aramid fiber 1313 fiber weight content is 35%. The linear density of the blended yarn was 14.7 tex x 2. The fabric structure is 2 / 1 twill weave, and the mass per unit area of gray fabric is 100g / m 2 .

[0052] The weaving process of this high voltage electrostatic fabric is the same as embodiment 1, the difference is:

[0053] In the weaving step, the fabric structure is 1 / 1 plain weave, and the machine parameters are: speed: 320r / min, height of the back beam: 1000mm, short front and rear positions, and flattening time: 330°.

[0054] The tentering and setting temperature is 180°C;

[0055] The above-me...

Embodiment 3

[0057] The high-voltage electrostatic protection fabric in this embodiment is formed by interweaving warp and weft yarns, and the warp and weft yarns are all blended yarns of metal fibers (stainless steel fibers), aramid 1414 fibers and nylon fibers, and the weight content of metal fibers in the blended yarns is 50 %, the weight content of aramid fiber 1414 is 35%, and the weight content of nylon fiber is 15%. The linear density of the blended yarn is 37tex×2. The fabric structure is 2 / 2 twill weave, and the mass per unit area of gray fabric is 400g / m 2 .

[0058] The weaving process of this high voltage electrostatic fabric is the same as embodiment 1, the difference is:

[0059] In the weaving step, the fabric structure is 1 / 1 plain weave, and the machine parameters are: speed: 260r / min, back beam height: 980mm, short front and rear positions, and flattening time: 330°.

[0060] The tentering and setting temperature is 160°C;

[0061] The above-mentioned fabrics also m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com