Preparation method for WO3-LDH composite film for photoelectrocatalytic water decomposition

A composite thin film, photoelectric catalysis technology, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problem that it cannot be used as a photocatalytic material, and achieve the effect of high separation efficiency, improved catalytic ability, and low oxygen evolution potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Weigh 0.5 g of ammonium tungstate and dissolve it in 30 ml of water, adjust the pH of the solution to 1 with 6 mol / L HCl solution, stir at 40°C until a colorless and transparent solution is formed, then transfer the solution to a 50 ml high pressure In the polytetrafluoroethylene lining of the reactor;

[0034] (2) Insert the pretreated FTO conductive glass sheet obliquely into the inner lining of the reactor so that the conductive side faces down;

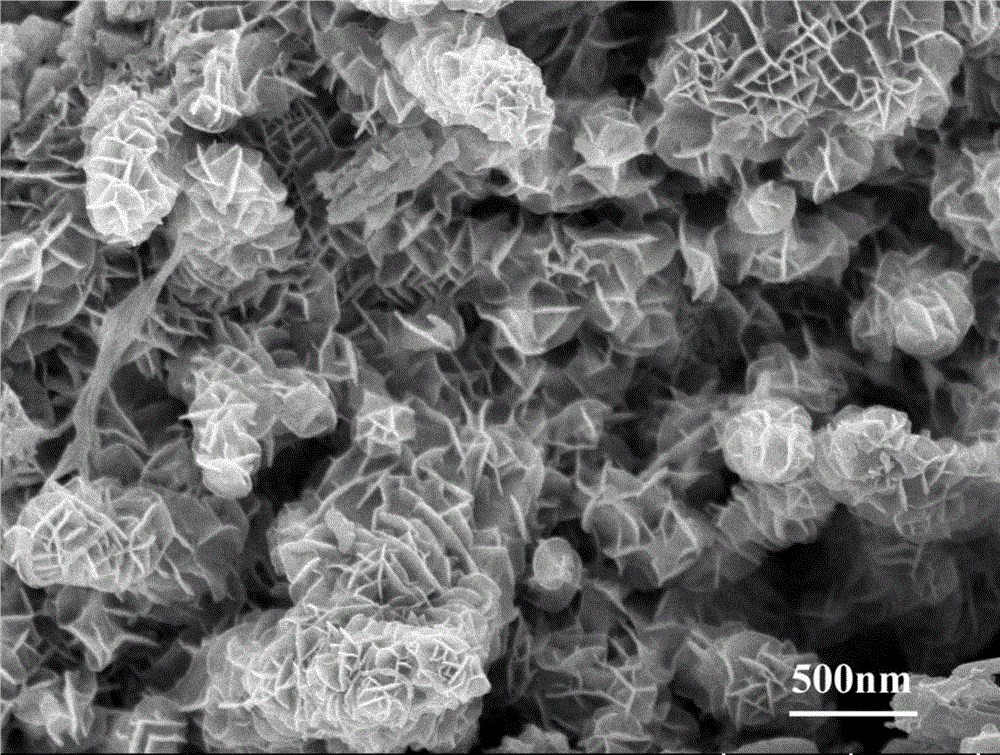

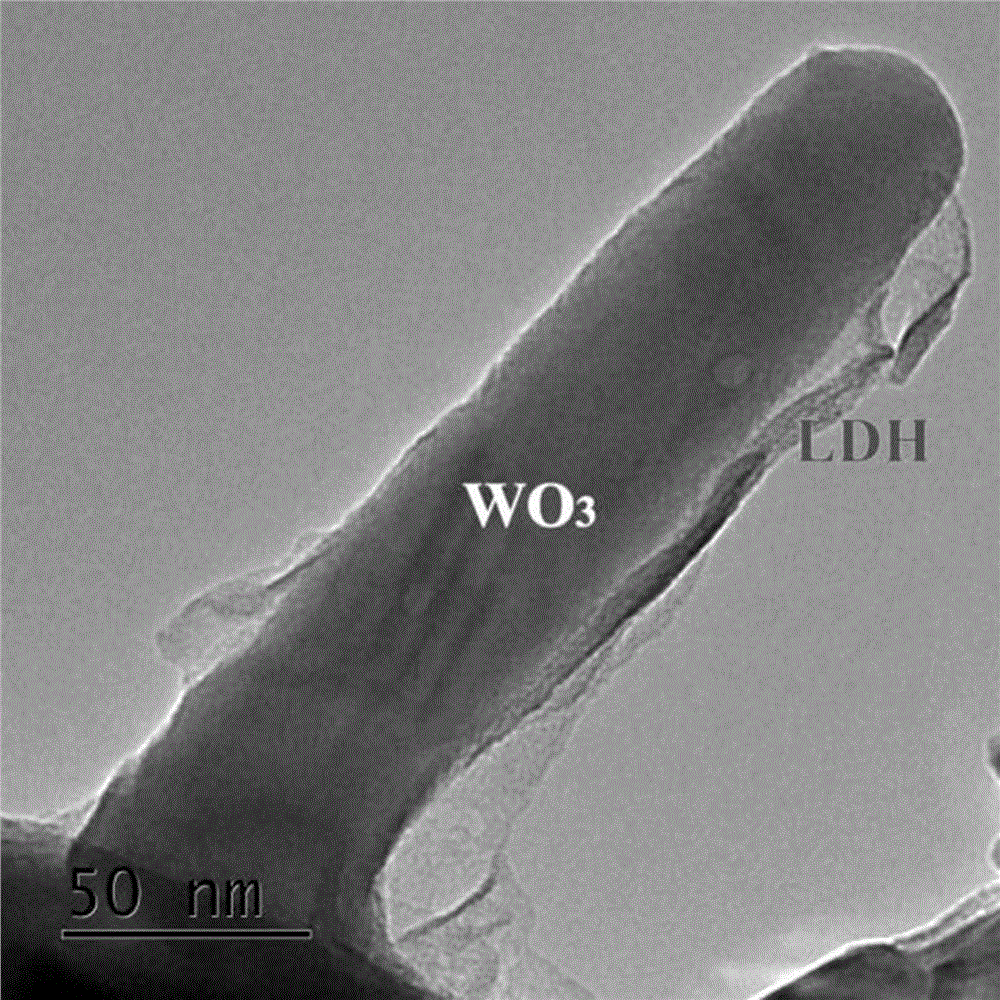

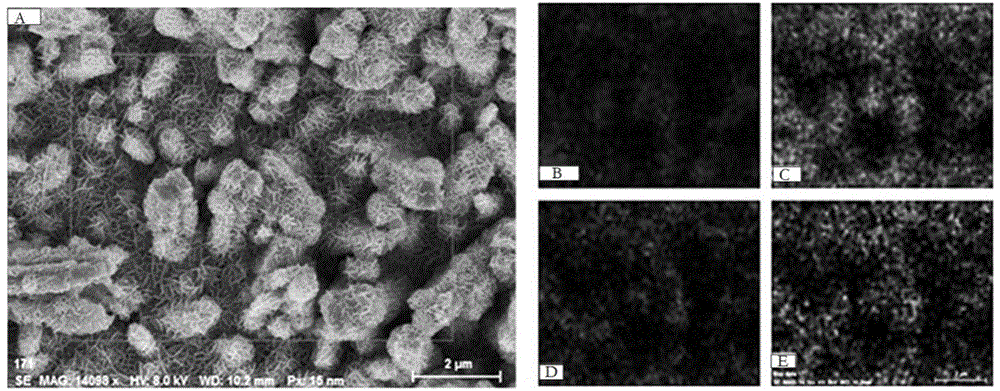

[0035] (3) Seal the reactor tightly and place it in an oven for solvothermal reaction, heat it at 180 °C for 5 h, cool it down to room temperature naturally, wash the conductive glass with deionized water and absolute ethanol, and dry it at 40 °C to obtain light cyan film;

[0036] (4) Under the protection of air atmosphere, the conductive glass with thin film was heat-treated at 500 °C for 2 h to obtain yellow WO 3 film.

[0037] (5) A three-electrode system is adopted, as follows: long with WO 3 The FTO conductive...

Embodiment 2

[0042] (1) Weigh 0.5 g of ammonium tungstate and dissolve it in 30 ml of water, adjust the pH of the solution to 1 with 6 mol / L HCl, stir at 40°C until a colorless and transparent solution is formed, then transfer to a 50 ml autoclave In the PTFE lining;

[0043] (2) Insert the pretreated FTO conductive glass sheet obliquely into the inner lining of the reactor so that the conductive side faces down;

[0044] (3) Seal the reactor tightly and put it in an oven for solvothermal reaction, react at 160°C for 1 hour, cool to room temperature naturally, wash the conductive glass with deionized water and absolute ethanol in turn, and dry it at 60°C to obtain a light blue color film;

[0045] (4) The obtained conductive glass with thin film was heat-treated at 450 ℃ under the protection of air atmosphere, and kept for 1 h to obtain yellow WO 3 film.

[0046] (5) Three-electrode system is adopted, with WO 3 The FTO conductive glass is used as the working electrode, the Pt sheet is ...

Embodiment 3

[0048] (1) Weigh 0.5 g of ammonium tungstate and dissolve it in 30 ml of water, adjust the pH of the solution to 1 with 6 mol / L HCl solution, stir at 40°C until a colorless and transparent solution is formed, then transfer to 50 ml of high pressure reaction In the polytetrafluoroethylene lining of the kettle;

[0049] (2) Insert the pretreated FTO conductive glass sheet obliquely into the inner lining of the reactor so that the conductive side faces down;

[0050] (3) Seal the reactor tightly and place it in an oven for solvothermal reaction, react at 200 °C for 7 h, cool to room temperature naturally, wash the conductive glass with deionized water and absolute ethanol and dry it at 100 °C to obtain a light cyan film ;

[0051] (4) The obtained conductive glass with thin film was heat-treated at 550 °C under the protection of air atmosphere, and kept for 2 h to obtain yellow WO 3 film.

[0052] (5) Three-electrode system is adopted, with WO 3 The FTO conductive glass is us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com