Flue gas treatment device and rotary hearth furnace high-temperature and high-dust glue gas treatment system

A flue gas treatment system and flue gas treatment technology, applied in waste heat treatment, steam generation device, combustion product treatment, etc., can solve problems affecting system operation stability, large temperature range of ash melting point, and reduced service life of water cooling walls , to achieve the effect of improving waste heat utilization rate and waste heat utilization effect, improving corrosion situation and reducing heating surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

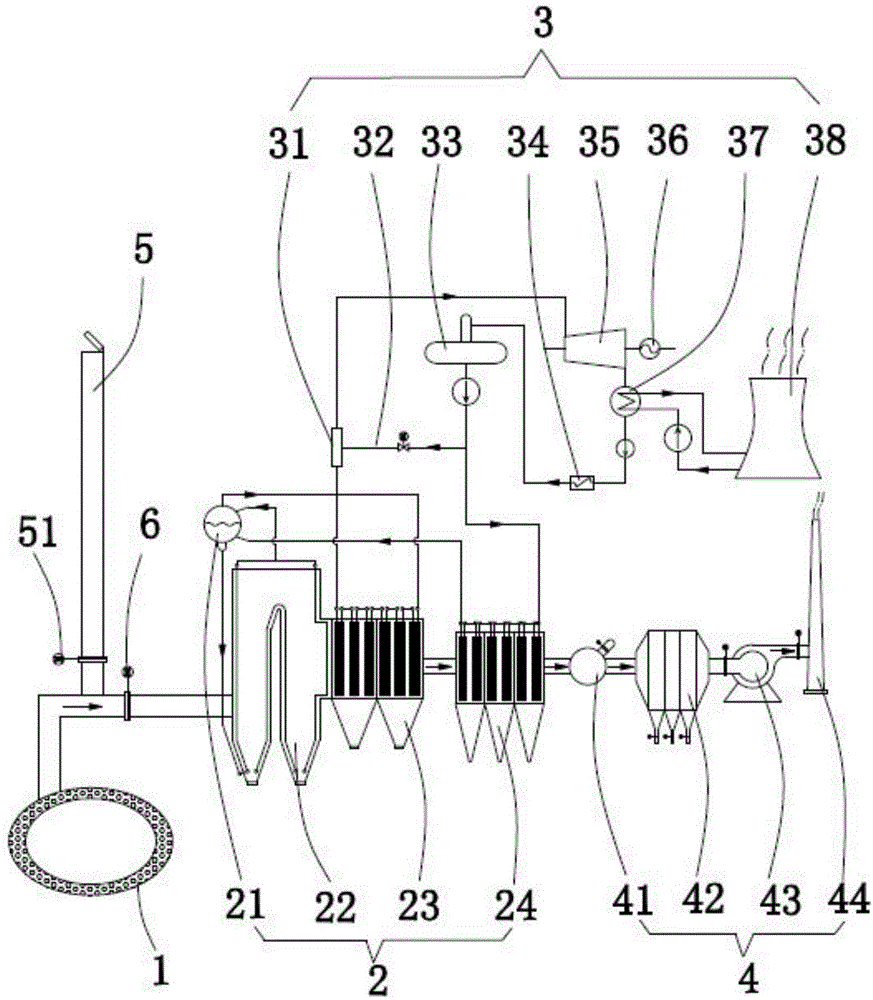

[0023] like figure 1 , the embodiment of the present invention provides a flue gas treatment device 2, which can be used to treat various flue gases produced in iron and steel plants, and is especially suitable for treating the high-temperature and high-dust flue gas produced by the rotary hearth furnace 1. The device includes a settling furnace 22, a high-temperature waste heat boiler 23, a low-temperature waste heat boiler 24, and a steam drum 21. The settling furnace 22, the high-temperature waste heat boiler 23 and the low-temperature waste heat boiler 24 are sequentially connected along the flow direction of flue gas. The flue gas inlet of 22 serves as the flue gas inlet of the flue gas treatment device 2 , and the flue gas outlet of the low-temperature waste heat boiler 24 serves as the flue gas outlet of the flue gas treatment device 2 . The settling furnace 22 is preferably in the shape of pants, and its flue gas inlet is located at the bottom of one of its trouser leg...

Embodiment 2

[0030] like figure 1 , this embodiment relates to a high-temperature and high-dust flue gas treatment system of a rotary hearth furnace, which is equipped with the flue gas treatment device 2 provided in the first embodiment above. The flue gas outlet of furnace 1 is connected. The system also includes a waste heat utilization subsystem 3, and the waste heat utilization subsystem 3 communicates with the heat exchange medium outlet of the high-temperature waste heat boiler 23 through a steam pipe.

[0031] Generally, the waste heat utilization subsystem 3 is mainly used for power generation, that is, the waste heat utilization subsystem 3 is a power generation system, and the waste heat utilization subsystem 3 includes a steam turbine 35 connected to a generator 36, and the steam turbine 35 The inlet communicates with the heat exchange medium outlet of the high-temperature waste heat boiler 23 through a steam pipe.

[0032] Further, as figure 1 , the steam outlet of the stea...

Embodiment 3

[0036] like figure 1 , this embodiment relates to a high-temperature and high-dust flue gas treatment system of a rotary hearth furnace, which is equipped with the flue gas treatment device 2 provided in the first embodiment above. The flue gas outlet of furnace 1 is connected. The system also includes a dust removal subsystem 4, and the dust removal subsystem 4 communicates with the flue gas outlet of the low-temperature waste heat boiler 24 through a low-temperature flue gas pipeline.

[0037] As one of the embodiments, the dedusting subsystem 4 includes a swirl mixer 41 and a bag filter 42 sequentially connected along the flue gas flow direction, and the swirl mixer 41 is provided with a cooling gas inlet controlled by a valve . The function of the swirling air mixer 41 is: when the working conditions that the filter bag of the bag filter 42 cannot withstand, the cooling gas (such as outdoor air) is introduced to mix with the flue gas through the opening of the valve cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com