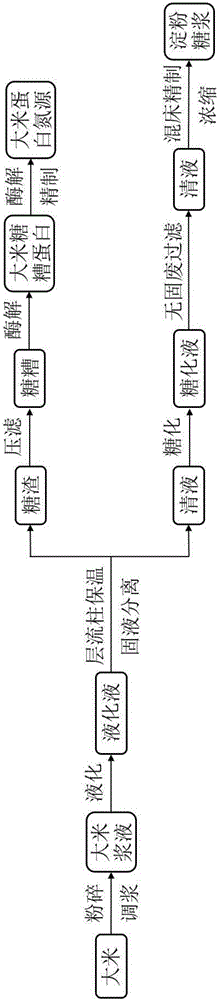

Production process for preparing starch syrup from rice

A production process and starch syrup technology, which is applied in the field of rice starch syrup preparation, can solve the problems of uneven particle size of rice crushing, affecting product quality, and long soaking time, so as to reduce insoluble starch particles, complete liquefaction effect, and increase solid content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1) Crushing and pulping: Weigh 100 parts by mass of rice, remove visible impurities and transport it to a rice washing tank, add water to soak, and feed compressed air to make the rice grains roll and rub, rinse the impurities on the surface of the rice grains, and release rice swill after rinsing , repeat once more, wash the rice grains, and then grind them into a slurry through a roller crushing homogenizer, add water at 54-55°C, adjust the pH value, and obtain the rice with a concentration of 25-26°Bé and a pH value of 5.6-5.7 rice slurry;

[0058] 2) Liquefaction: Add Liquozyme Supra 2.2X α-amylase accounting for 0.03% of the rice mass to the rice slurry, stir evenly, perform primary jet liquefaction at 100-102°C, keep warm for 30 minutes after flash evaporation, and then heat at 125-126°C Perform secondary jet liquefaction at ℃ to obtain liquefied liquid;

[0059] 3) Laminar flow column for heat preservation and solid-liquid separation: After the liquefied liquid ...

Embodiment 2

[0066] 1) Crushing and pulping: Weigh 100 parts by mass of rice, remove visible impurities and transport it to a rice washing tank, add water to soak, and feed compressed air to make the rice grains roll and rub, rinse the impurities on the surface of the rice grains, and release rice swill after rinsing , repeat once more, wash the rice grains, and then grind them into a slurry with a roller crushing homogenizer, add 56-57°C water, adjust the pH value, and obtain the rice with a concentration of 27-28°Bé and a pH value of 5.8-5.9 rice slurry;

[0067] 2) Liquefaction: Add Liquozyme Supra α-amylase accounting for 0.04% of rice mass to the rice slurry, stir evenly, perform primary jet liquefaction at 104-105°C, keep warm for 40 minutes after flash evaporation, and then heat at 128-129°C Perform secondary jet liquefaction to obtain liquefied liquid;

[0068] 3) Laminar flow column for heat preservation and solid-liquid separation: After the liquefied liquid is flashed to reduce...

Embodiment 3

[0075] 1) Crushing and pulping: Weigh 100 parts by mass of rice, remove visible impurities and transport it to a rice washing tank, add water to soak, and feed compressed air to make the rice grains roll and rub, rinse the impurities on the surface of the rice grains, and release rice swill after rinsing , repeat once more, wash the rice grains, and then grind them into a slurry with a roller crushing homogenizer, add water at 55-56°C, adjust the pH value, and obtain the rice with a concentration of 26-27°Bé and a pH value of 5.7-5.8 rice slurry;

[0076] 2) Liquefaction: Add Liquozyme Supra 2.2X α-amylase accounting for 0.02% of the rice mass to the rice slurry, stir evenly, perform primary jet liquefaction at 99-100°C, keep warm for 50 minutes after flash evaporation, and then heat at 126-127°C Perform secondary jet liquefaction at ℃ to obtain liquefied liquid;

[0077] 3) Laminar flow column for heat preservation and solid-liquid separation: After the liquefied liquid is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com