Silicone resin type two-component elastic silicone sealant for insulating glass and preparation method thereof

A silicone sealant and silicone resin technology, applied in the field of sealants, can solve the problems of small compression set and unsatisfactory performance, and achieve the effects of small compression set, improved mechanical strength and good insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

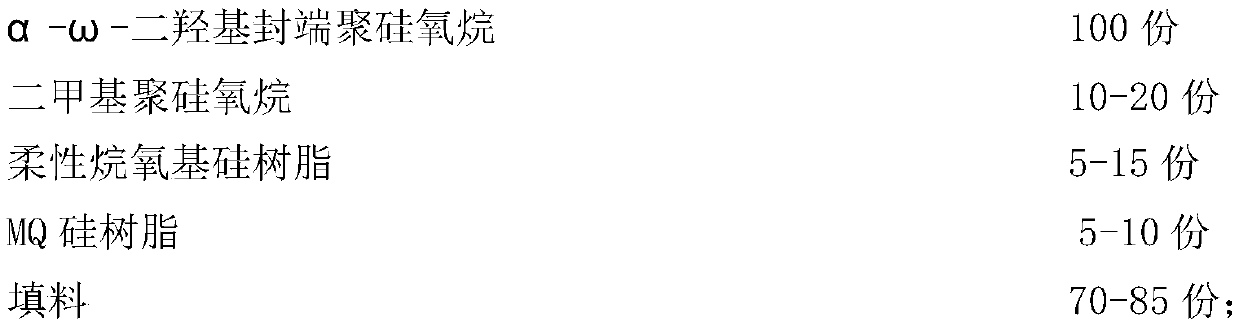

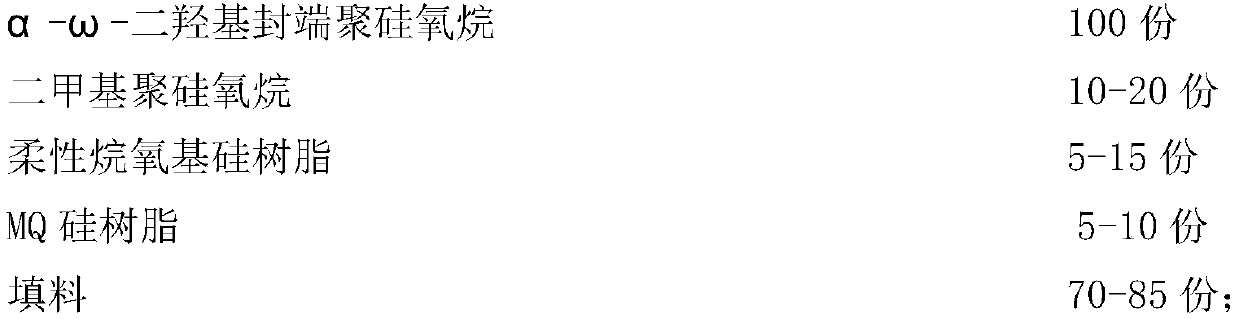

[0052] A silicone type two-component elastic silicone sealant for insulating glass, comprising A component and B component, composed as follows by weight:

[0053] Component A: 100 parts of α-ω-dihydroxyl-terminated polysiloxane with a viscosity of 7000 cp, 15 parts of dimethylpolysiloxane with a viscosity of 500 cp, D chain (flexible chain) and T chain ( Rigid chain link) 10 parts of methyl ethoxy silicone resin with a molar ratio of 4:1, 7 parts of methyl MQ silicone resin (the ratio of M / Q is 0.8), 5 parts of fumed white carbon black, 50 parts of nano-active calcium carbonate part, 20 parts of heavy calcium carbonate;

[0054] Component B: 50 parts of dimethyl polysiloxane with a viscosity of 700cp, 7 parts of carbon black, 7 parts of tetraethoxysilane, 12 parts of polymethyltriethoxysilane, γ-aminopropyl triethoxy 10 parts of silane, 0.5 part of ethyl diacetoacetate diisopropyl titanate, 1 part of dibutyltin dilaurate, and 0.05 part of cyanoacrylate.

[0055] The prepara...

Embodiment 2

[0061] A silicone type two-component elastic silicone sealant for insulating glass, comprising A component and B component, composed as follows by weight:

[0062] Component A: 100 parts of α-ω-dihydroxyl-terminated polysiloxane with a viscosity of 6000 cp, 12 parts of dimethyl polysiloxane with a viscosity of 600 cp, and the molar ratio of D chain unit to T chain unit is 3:1 8 parts of methyl methoxy silicone resin, 7 parts of phenyl MQ silicone resin (the ratio of M / Q is 0.8), 10 parts of fumed silica, 40 parts of nano-active calcium carbonate, 20 parts of heavy calcium carbonate;

[0063] Component B: 50 parts of dimethylpolysiloxane with a viscosity of 900cp, 7 parts of carbon black, 9 parts of propyl orthosilicate, 12 parts of polymethyltriethoxysilane, and 10 parts of tetraisopropyl titanate , 0.5 part of ethyl diacetoacetate diisopropyl titanate, 1 part of dibutyltin dilaurate, and 0.05 part of benzotriazole compound.

[0064] The preparation steps are as follows:

[...

Embodiment 3

[0070] A silicone type two-component elastic silicone sealant for insulating glass, comprising A component and B component, composed as follows by weight:

[0071] Component A: 100 parts of α-ω-dihydroxyl-terminated polysiloxane with a viscosity of 8000 cp, 10 parts of dimethyl polysiloxane with a viscosity of 200 cp, and the molar ratio of D chain unit to T chain unit is 10:1 11 parts of phenylethoxy silicone resins, 6 parts of phenyl MQ silicone resins (the ratio of M / Q is 1), 4 parts of fumed silica, 50 parts of nano-active calcium carbonate, 20 parts of heavy calcium carbonate;

[0072] Component B: 50 parts of dimethylpolysiloxane with a viscosity of 200cp, 7 parts of carbon black, 7 parts of tetraethyl orthosilicate, 12 parts of methyltriethoxysilane, N-β-(aminoethyl) - 10 parts of γ-aminopropyltrimethoxysilane, 0.5 parts of ethyl diacetoacetate diisopropyl titanate, 1.2 parts of dibutyltin dilaurate, and 0.05 parts of benzophenone compound;

[0073] The preparation ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com