A tire with polyurethane elastomer material inside and its preparation method

A technology of polyurethane elastomer and polyurethane elasticity, which is applied in the direction of polyurea/polyurethane coating, polyurea/polyurethane adhesive, special tires, etc., can solve the problems of difficult processing and high processing cost, achieve low hardness and prevent tire leakage The effect of air deviation and high deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

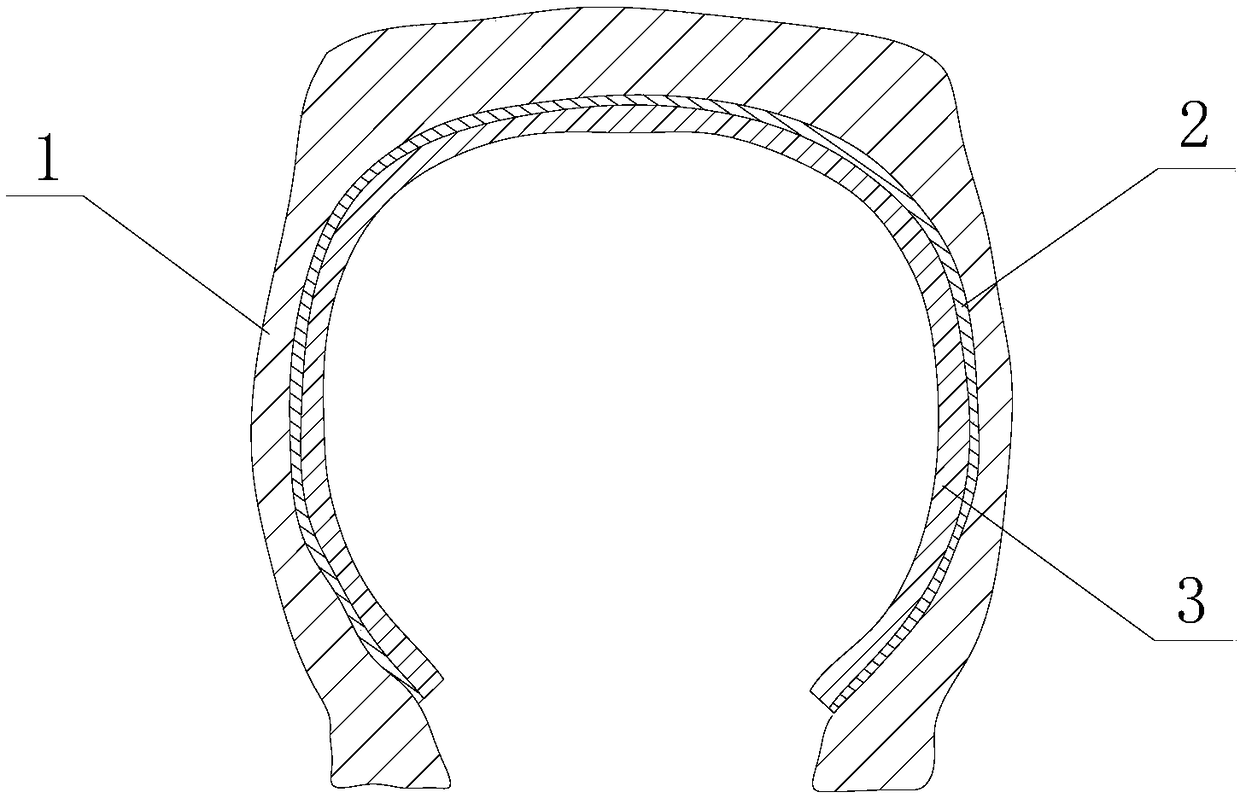

[0042] A tire with a polyurethane elastomer material inside in this embodiment includes a tire body 1, wherein: the tire with a polyurethane elastomer material inside also includes a polyurethane primer layer 2 and a polyurethane elastomer layer 3, so The polyurethane primer layer 2 and the polyurethane elastomer layer 3 are sequentially arranged on the inner surface of the tire body 1 from inside to outside, and the total thickness of the polyurethane primer layer and the polyurethane elastomer layer is 3-4 mm.

[0043] The material used for the polyurethane primer 2 is composed of A component and B component with a mass ratio of 1:1,

[0044] The A component consists of the following raw materials in weight ratio:

[0045] 20 parts of castor oil, 12 parts of butyl acetate, 38 parts of polymethylene polyphenylisocyanate and 30 parts of trichlorethylene;

[0046] Described B component is made up of the raw material of following weight ratio:

[0047] 40 parts of polytetrahyd...

Embodiment 2

[0063] A tire with a polyurethane elastomer material in this embodiment is the same as that in Embodiment 1.

[0064] The material used for the polyurethane primer 2 is composed of A component and B component with a mass ratio of 1:1,

[0065] The A component consists of the following raw materials in weight ratio:

[0066] 25 parts of castor oil, 7 parts of butyl acetate, 33 parts of polymethylene polyphenylisocyanate and 35 parts of trichlorethylene;

[0067] Described B component is made up of the raw material of following weight ratio:

[0068] 60 parts of polytetrahydrofuran diol with a relative molecular mass of 1000 and 40 parts of xylene.

[0069] The material for the polyurethane base coat 2 is made by the following steps:

[0070] (1) Synthesis of component A: put 25 parts of castor oil in a reactor with a condenser, dehydrate for 2 hours at 120°C and a vacuum of -0.09Mpa, cool down to 40°C after dehydration, and take acetic acid Add 7 parts of butyl ester into t...

Embodiment 3

[0084] A tire with a polyurethane elastomer material in this embodiment is the same as that in Embodiment 1.

[0085] The material used for the polyurethane primer 2 is composed of A component and B component with a mass ratio of 1:1,

[0086] The A component consists of the following raw materials in weight ratio:

[0087] 21 parts of castor oil, 11 parts of butyl acetate, 37 parts of polymethylene polyphenylisocyanate and 31 parts of trichlorethylene;

[0088] Described B component is made up of the raw material of following weight ratio:

[0089] 45 parts of polytetrahydrofuran diol with a relative molecular mass of 1000 and 55 parts of xylene.

[0090] The material for the polyurethane base coat 2 is made by the following steps:

[0091] (1) Synthesis of component A: put 21 parts of castor oil in a reactor with a condenser, dehydrate for 2 hours at 120°C and a vacuum of -0.09Mpa, cool down to 40°C after dehydration, and take acetic acid Add 11 parts of butyl ester into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com