Environment-friendly composite material for solar photovoltaic cell backplane

A photovoltaic cell and composite material technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as poor mechanical properties and weather resistance, and achieve the effects of low production cost, low toxicity, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the environmentally friendly composite material for the solar photovoltaic battery backplane comprises the following steps:

[0031] S1: Mix polyurethane, monoglyceride stearate, pentaerythritol rosin ester, carbon nanotubes, PBT, PVDF, and polysulfide rubber, and stir for 15-25min at a temperature of 650-720°C and a speed of 100-300r / min. Preparation of mixture I;

[0032] S2: Under nitrogen protection, add polyhexene, ABS, glyceryl tristearate, glass micropowder, citric acid ester, tris[2,4-di-tert-butylphenyl ] Phosphite, silicon carbide fiber, AR glass fiber, γ-methacryloxypropyltrimethoxysilane, KH570 silane coupling agent, acrylic compatibilizer, acrylic bridging agent, acrylate rubber, Dioctyl adipate and a chain extender were stirred for 3.5-6.5 hours at a microwave power of 120-250W, a temperature of 600-620°C, and a rotation speed of 200-400r / min to obtain mixture II;

[0033] S3: Add ultraviolet absorber, light stabilizer, anti-agi...

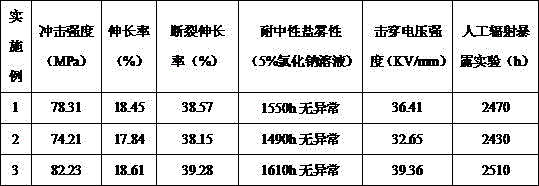

Embodiment 1

[0036] An environmentally friendly composite material for solar photovoltaic battery backplanes, made of the following raw materials in units of weight: 75 parts of polyurethane, 42 parts of monoglyceride stearate, 25 parts of pentaerythritol rosin ester, 15 parts of carbon nanotubes, and 18 parts of PBT , 10 parts of PVDF, 2.5 parts of polysulfide rubber, 6 parts of polyhexene chloride, 2 parts of ABS, 2 parts of glyceryl tristearate, 1.5 parts of glass micropowder, 8 parts of citrate, tris[2,4-ditertiary 7 parts of butylphenyl] phosphite, 4 parts of silicon carbide fiber, 3 parts of AR glass fiber, 1.5 parts of γ-methacryloxypropyl trimethoxysilane, 1.3 parts of KH570 silane coupling agent, acrylic type 1 part of compatibilizer, 1 part of acrylic bridging agent, 1.2 parts of acrylate rubber, 0.8 part of dioctyl adipate, 0.9 part of chain extender, 1 part of ultraviolet absorber, 0.8 part of light stabilizer, anti-aging agent 1.2 parts, 0.6 parts of antioxidant, 1.2 parts of ...

Embodiment 2

[0049] An environmentally friendly composite material for solar photovoltaic battery backplanes, made of the following raw materials in units of weight: 65 parts of polyurethane, 40 parts of monoglyceride stearate, 24 parts of pentaerythritol rosin ester, 12 parts of carbon nanotubes, and 16 parts of PBT , 10 parts of PVDF, 2 parts of polysulfide rubber, 5 parts of polyhexene chloride, 1 part of ABS, 1 part of glyceryl tristearate, 1 part of glass micropowder, 7 parts of citric acid ester, tris[2,4-ditertiary 5 parts of butylphenyl] phosphite, 2 parts of silicon carbide fiber, 2 parts of AR glass fiber, 1 part of γ-methacryloxypropyl trimethoxysilane, 0.8 part of KH570 silane coupling agent, acrylic type 0.8 parts of compatibilizer, 0.7 parts of acrylic bridging agent, 0.9 parts of acrylate rubber, 0.6 parts of dioctyl adipate, 0.6 parts of chain extender, 0.5 parts of ultraviolet absorber, 0.5 parts of light stabilizer, anti-aging agent 0.9 parts, 0.4 parts of antioxidant, 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com