Preparation method of hollow carbon nanospheres

A nano-carbon sphere and hollow technology, applied in the direction of nanotechnology, can solve the problems of cumbersome process and poor controllability, and achieve the effect of less process steps, short reaction time and rounded spheres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of hollow nano carbon spheres of the present invention comprises the following steps:

[0028] s1. Provide nano-carbon sphere precursors with a particle size of 100-1000nm;

[0029] s2. Fully grind and disperse the carbon nanosphere precursor described in step s1 into a powder, then spread the powder in a crucible, and place the crucible in a muffle furnace for calcination to obtain the target product. The particle size of the target product is determined by the particle size of the precursor, which is 100-1000nm.

[0030] The calcination treatment conditions include: the calcination temperature is 300-800°C, the heating rate is above 2°C / min, the holding time is 0.2-12h, and the calcination atmosphere is air.

[0031] In the step s1, the preparation process of the nano-carbon sphere template includes: using glucose as a carbon source to perform a hydrothermal reaction to obtain nano-carbon spheres.

[0032] As one of the preferred specific appl...

Embodiment 1

[0037] s1. Take the nano-carbon sphere precursor with a particle size of 100-150nm and fully grind it with a mortar for more than 2 minutes, and disperse it into a powder;

[0038] s2. Spread the above-mentioned nano-carbon sphere powder on a crucible, place the crucible in a muffle furnace, and raise the temperature to 450° C. at a heating rate of 10° C. / min in an air atmosphere and keep it warm for 60 minutes to obtain hollow nano-carbons. ball.

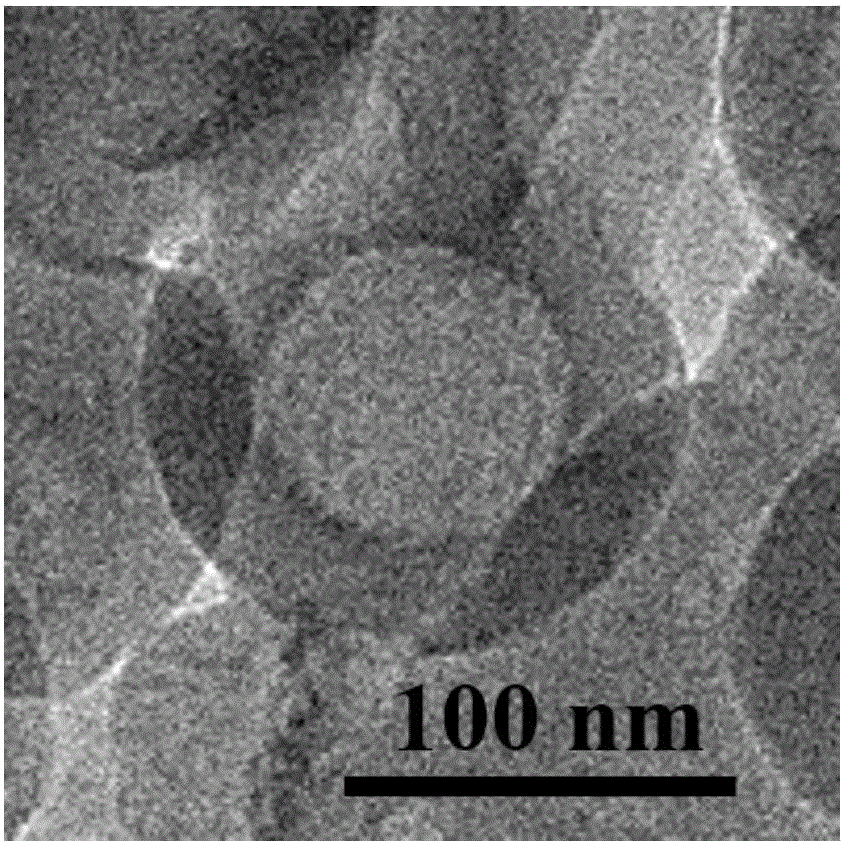

[0039] figure 1 Shown is the transmission electron microscope photo of the hollow carbon nanospheres obtained in Example 1. It can be seen from the figure that the diameter of the hollow carbon nanospheres is 140 nm and the wall thickness is about 44 nm.

Embodiment 2

[0041] s1. Take the nano-carbon sphere precursor with a particle size of 100-150nm and fully grind it with a mortar for more than 2 minutes, and disperse it into a powder;

[0042] S2. Spread the above-mentioned nano-carbon sphere powder in a crucible, place the crucible in a muffle furnace, and in an air atmosphere, raise the temperature to 450 °C at a heating rate of 10 °C / min and keep it warm for 90 min to obtain hollow nano-carbon ball.

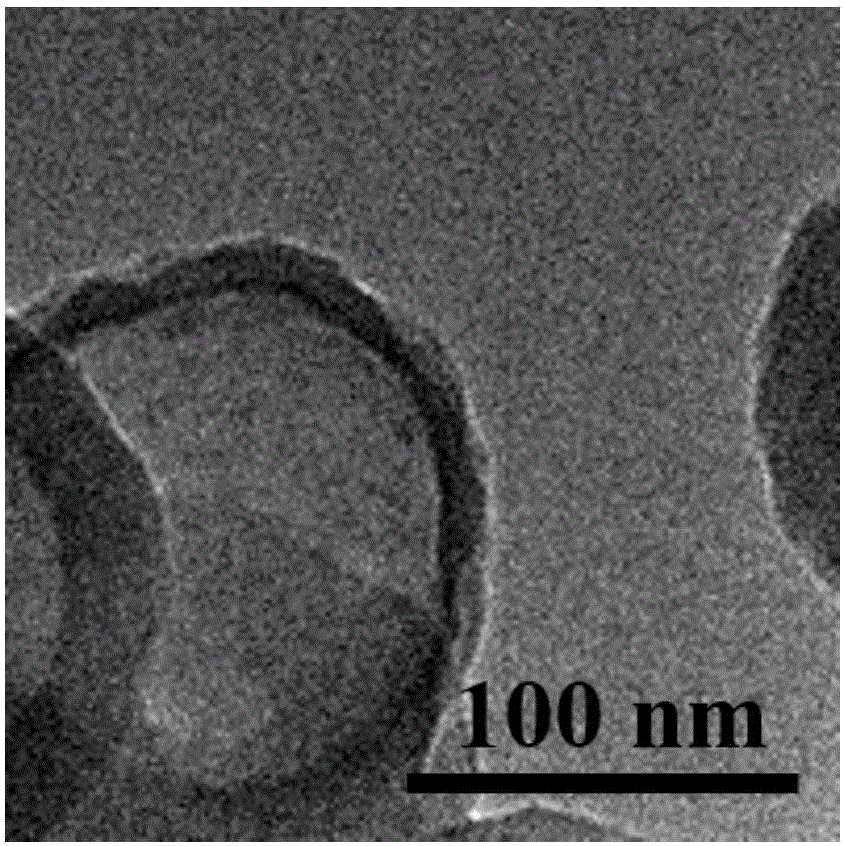

[0043] figure 2 Shown is the transmission electron microscope photo of the hollow carbon nanospheres obtained in Example 2. It can be seen from the figure that the diameter of the hollow carbon nanospheres is 132nm and the wall thickness is about 29nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com