Degradable starch microsphere with rough surface structure, and preparation method thereof

A technology for degrading starch and rough surface is applied in the field of preparation of degradable microbeads with rough surface structure, which can solve the problems of easily broken microsphere structure of microsphere structure, poor shape stability of starch microspheres, insufficient roundness, etc. The effect of uniform distribution, low price and rounded sphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of degradable starch microbeads with a rough surface structure, comprising the steps of:

[0029] Step 1. Modification of raw starch: using raw starch as raw material, using cationic etherification agent to carry out cationic etherification treatment on the raw starch, and then using esterification agent to carry out esterification treatment on the raw starch after etherification treatment;

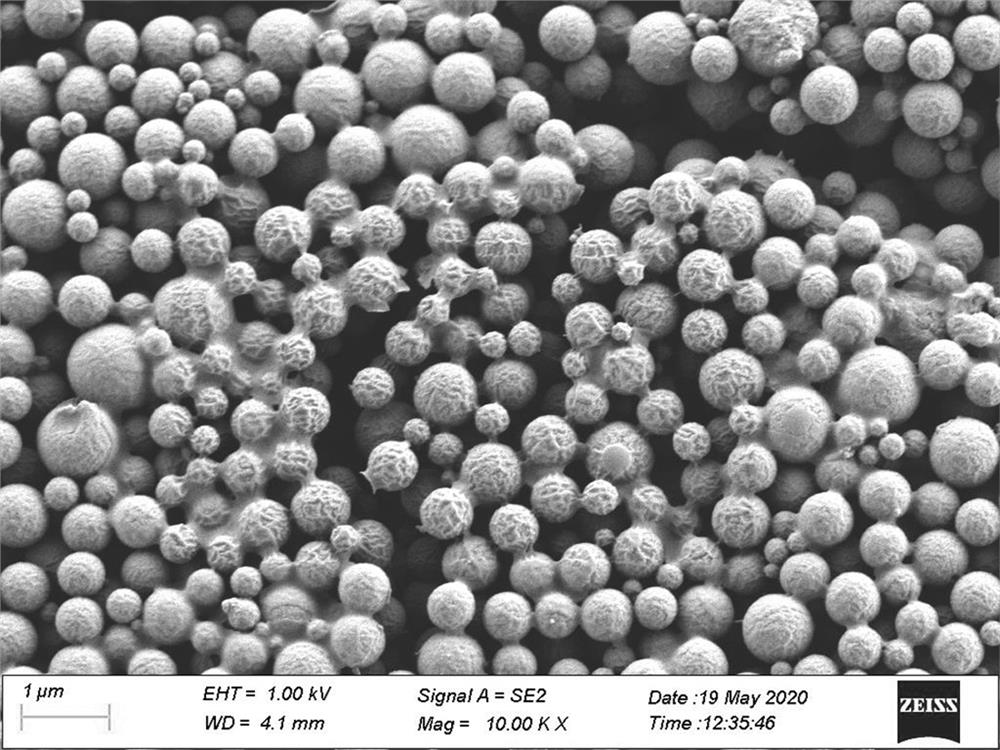

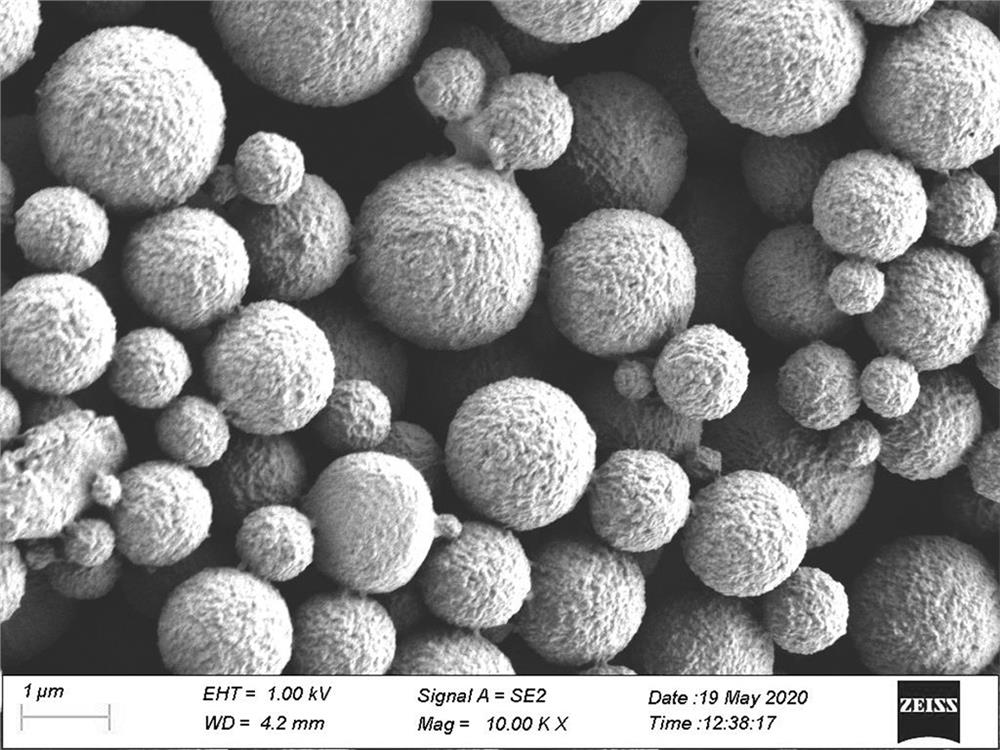

[0030] Step ② Preparation of starch microbeads: use co-precipitation method to prepare degradable starch microbeads, dissolve the modified raw starch in step ① in an organic solvent, and then mix it with water. After the organic solvent is completely volatilized, water is obtained. After the dispersed starch microbead solution is dried, degradable starch microbeads with a rough surface structure are finally obtained.

[0031] In the step ①, the mass ratio of the native starch to the cationic etherifying agent is 10:1~10, and in the step ② the mass ratio of the ...

Embodiment 1

[0044] Step ① Modification of starch

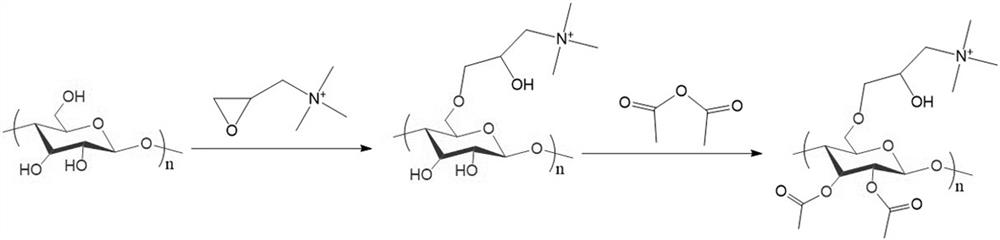

[0045] In the embodiment of the present invention, the original starch is corn starch, the cationic etherification agent is 2, 3-epoxypropyltrimethylammonium chloride (GTA), the esterification agent is acetic anhydride, and the cationic etherification method It is a wet method; the mass ratio of raw starch: cationic etherifying agent: esterifying agent is 10:2:10; 2, 3-epoxypropyltrimethylammonium chloride etherifying agent is used, and acetic anhydride is esterified The reaction process for the preparation of modified starch is as follows:figure 1 shown.

[0046] In a 250 mL three-neck flask equipped with a reflux condenser, a stirring device and a thermometer, add the dried raw starch to a 50 mL concentration of sodium hydroxide (1%wt) solution, mix and stir at 30 ° C for 1 hour; then reverse reaction Add GTA solution (70%wt) dropwise to the system for etherification reaction; cool after the reaction, soak the product in ethanol soluti...

Embodiment 2

[0051] Step ① Modification of starch

[0052] In the embodiment of the present invention, the original starch is tapioca starch, the cationic etherification agent is 3-chloro-2-hydroxypropyltrimethylammonium chloride (CTA), the esterification agent is propionic anhydride, and the cationic etherification agent is The method is a semi-dry method; the mass ratio of raw starch: cationic etherifying agent: esterifying agent is 10:1:20.

[0053] Before the reaction, the raw starch was dried at 60 °C for 24 h to remove water. First, dissolve a certain amount of NaOH in a certain amount of water and cool to room temperature. Then add the etherifying agent (CTA) and let it stand for 5 minutes. Finally, spray the alkali solution of the etherifying agent on 10 g of tapioca starch in a stainless steel plate and stir evenly. Put it into an oven for pre-drying at 60°C for 1 h, control the water content below 14%, and then react at a specified temperature for a certain period of time. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com