Tread rubber cooling water high-pressure blowing device

A high-pressure blowing and cooling water technology, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of unfavorable tread rubber production efficiency, unreasonable structural design, and unsatisfactory cooling effect, etc., to achieve good cooling effect, Flexible and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

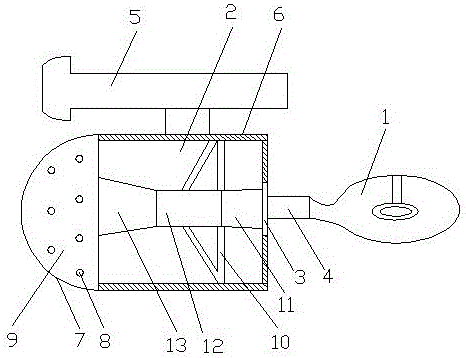

[0026] see figure 1 , a tread rubber cooling water high-pressure purging device, including a high-pressure blower 1 and a purge chamber 2, the purge chamber 2 is provided with an air inlet 3, and the high-pressure blower 1 passes through the intake pipe 4 and the air intake of the purge chamber 2 port 3, and also includes a shower 5 arranged on the purge chamber 2. The purge chamber 2 includes a box body 6 and a purge panel 7 connected to the box body 6. The purge panel 7 is in the shape of a hemisphere A plurality of blowing holes 8 are evenly distributed on the purge panel 7, and the purge panel 7 and the outer wall of the box body 6 form a purge cavity 9, and the box body 6 is provided with a venturi tube and a connecting frame 10, and the venturi The tube is formed by connecting a constriction section 11, a cylindrical section 12 and an expansion section 13. The Venturi tube is connected to the inner wall of the box body 6 through a connecting frame 10. The air inlet pipe ...

Embodiment 2

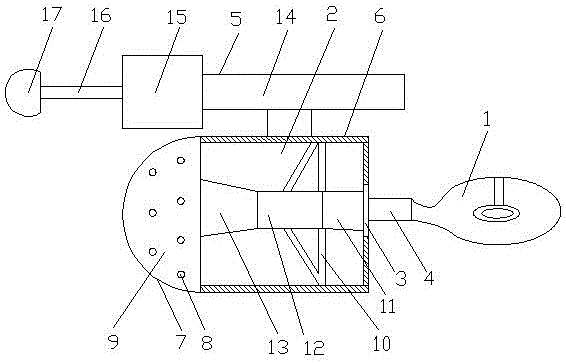

[0029] see figure 2 , a tread rubber cooling water high-pressure purging device, including a high-pressure blower 1 and a purge chamber 2, the purge chamber 2 is provided with an air inlet 3, and the high-pressure blower 1 passes through the intake pipe 4 and the air intake of the purge chamber 2 port 3, and also includes a shower 5 arranged on the purge chamber 2. The purge chamber 2 includes a box body 6 and a purge panel 7 connected to the box body 6. The purge panel 7 is in the shape of a hemisphere A plurality of blowing holes 8 are evenly distributed on the purge panel 7, and the purge panel 7 and the outer wall of the box body 6 form a purge cavity 9, and the box body 6 is provided with a venturi tube and a connecting frame 10, and the venturi The tube is formed by connecting a constriction section 11, a cylindrical section 12 and an expansion section 13. The Venturi tube is connected to the inner wall of the box body 6 through a connecting frame 10. The air inlet pipe...

Embodiment 3

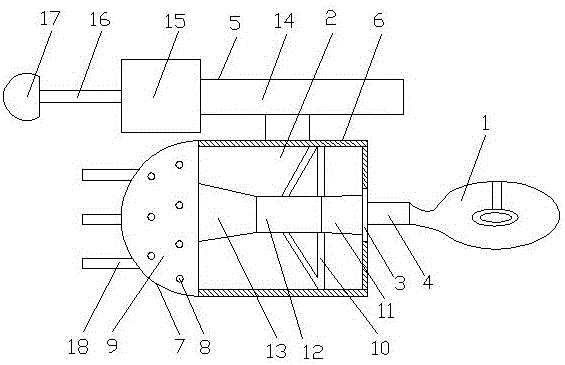

[0033] see image 3 , a high-pressure purging device for tread rubber cooling water, comprising a high-pressure blower 1 and a purge chamber 2, the purge chamber 2 is provided with an air inlet 3, and the high-pressure blower 1 passes through the intake pipe 4 and the air intake of the purge chamber 2 port 3, and also includes a shower 5 arranged on the purge chamber 2. The purge chamber 2 includes a box body 6 and a purge panel 7 connected to the box body 6. The purge panel 7 is in the shape of a hemisphere A plurality of blowing holes 8 are evenly distributed on the purge panel 7, and the purge panel 7 and the outer wall of the box body 6 form a purge cavity 9, and the box body 6 is provided with a venturi tube and a connecting frame 10, and the venturi The pipe is formed by connecting a shrinkage section 11, a cylindrical section 12 and an expansion section 13. The Venturi tube is connected to the inner wall of the box body 6 through a connecting frame 10. The air inlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com