Drilling production line for brackets on suspensions

A production line and suspension technology, used in boring/drilling, drilling/drilling equipment, support, etc., can solve the problems of production efficiency bottleneck, high scrap rate, low manual drilling efficiency, etc., to ensure drilling Quality, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

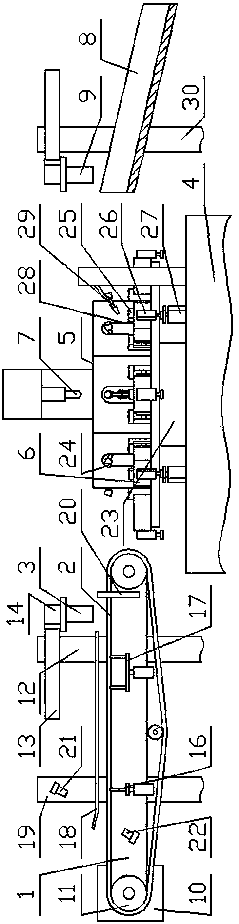

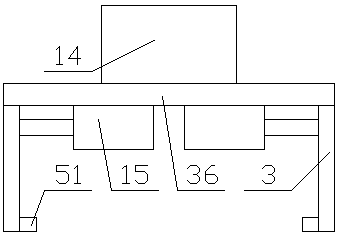

[0055] combine Figure 1~Figure 7 As shown, the present invention comprises feeding conveying device, drilling device and discharging device successively, and described feeding conveying device comprises two parallel conveying frames 1, and the outside of described conveying frame 1 is wound with conveyer belt 2, and described conveyer belt 2. Transmission connection through the transmission roller 11, the transmission roller 11 is connected with the conveying frame 1 through the rotating shaft A, the driving force of the rotating shaft A is provided by the motor A10, and the motor A10 is fixedly connected with the conveying frame 1; Between, be positioned at the end that conveyer frame 1 faces drilling device and be provided with positioning baffle 20, be positioned at the top of positioning baffle 20 and be provided with loading clip 3; Described discharge device comprises discharge slide rail 8, and described discharge slide The rail 8 is inclined downward along the end awa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com