Hybrid dendritic polymer supported metal catalyst and preparation method and application thereof

A dendrimer, metal-loaded technology, used in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, catalytic reactions, etc., can solve the problem of increased production costs and large metal residues in hydrogenated polymers , damage the physical and chemical properties of the polymer and other problems, to achieve excellent catalytic hydrogenation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 The second generation of hybrid dendrimers loaded with rhodium and ruthenium metal and its catalytic hydrogenation of unsaturated diene polymers

[0036] 1. Surface-modified second-generation polypropyleneimine dendrimers (G 2 -M) Synthesis with reference to Chinese invention patent application 2014104623745: take 2.155g (2.79×10 -3 mol)G 2 PPI (Netherlands SyMO-Chem B.V company) was dissolved in 10ml acetonitrile for later use. 0.48g (4.8×10 -4 mol)1,11-bis[2,4,6-triisopropylbenzenesulfonyl]-6-[4-(3-bromopropyl)benzenesulfonyl]-1,6,11-triazacyclodeca Pentadecane-3,8,13-triene (MAC), 0.33g (2.4×10 -3 mol) of anhydrous potassium carbonate is placed in a reaction flask with a reflux and ventilation device. Connect the external ventilation device and replace the N 2 three times. Under normal temperature stirring, inject 0.24mlG into the flask successively 2 PPI / acetonitrile solution and 30ml acetonitrile. The temperature was raised to 107°C for 12 hours....

Embodiment 2

[0049] Example 2 The second generation of hybrid dendrimers supported rhodium and ruthenium metal and its catalytic hydrogenation of unsaturated diene polymers

[0050] 1. G 2 -M loaded ruthenium rhodium metal (G 2 -M(Rh 3+ 50 Ru 3+ 50 )) Catalyst preparation

[0051] Take 0.12g G 2 -M The second generation polypropylene imine polymer (G 2 -M) placed in a reaction bottle equipped with a ventilator, connected to an external ventilator, and replaced with N 2 three times. Under stirring at room temperature, 50 ml of tetrahydrofuran was added into the bottle, and then 0.5 ml of rhodium trichloride with a concentration of 0.1 mol / L and 0.5 ml of a ruthenium trichloride solution with a concentration of 0.1 mol / L were added. After stirring at room temperature for 24h, the hybrid dendrimer supported rhodium-ruthenium bimetallic catalyst G can be obtained 2 -M(Ru 3+ 50 Rh 3 + 50 ).

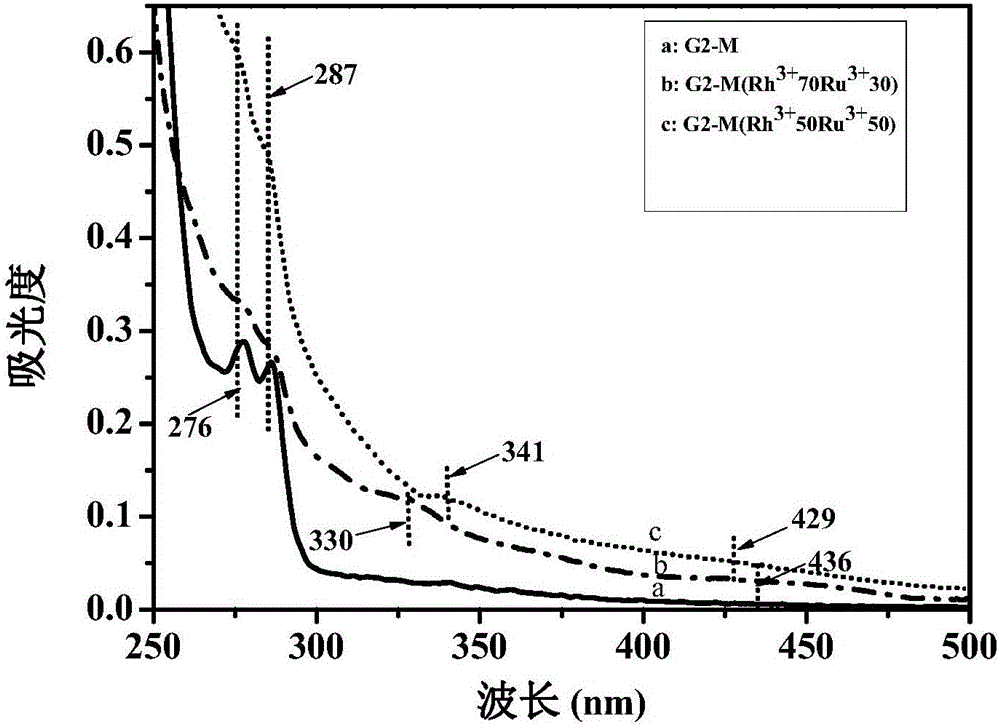

[0052] G 2 -M(Ru 3+ 50 Rh 3+ 50 ) UV absorption spectrum such as Figure 1-2 show...

Embodiment 3

[0061] Example 3 The second generation of hybrid dendrimers supported rhodium palladium metal and its catalytic hydrogenation of unsaturated diene polymers

[0062] 1. G 2 -M(Rh 3+ 70 PD 2+ 30 ) preparation

[0063] Take 0.12g G2-M and place it in a reaction bottle equipped with a ventilation device, connect the external ventilation device, and replace N 2 three times. Under normal temperature stirring, 50ml of tetrahydrofuran was added into the bottle, and then 0.7ml of 0.1mol / L rhodium trichloride and 0.3ml of 0.1mol / L palladium acetate solution were added. After stirring at room temperature for 26h, G 2 -M(Rh 3+ 70 PD 2+ 30 ).

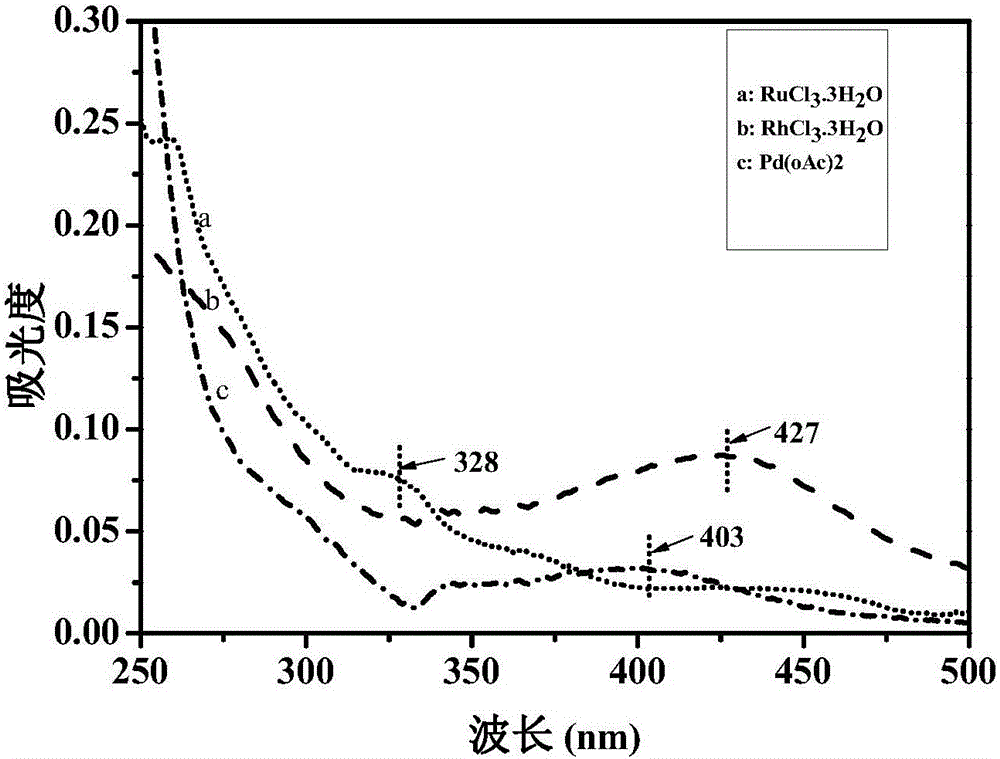

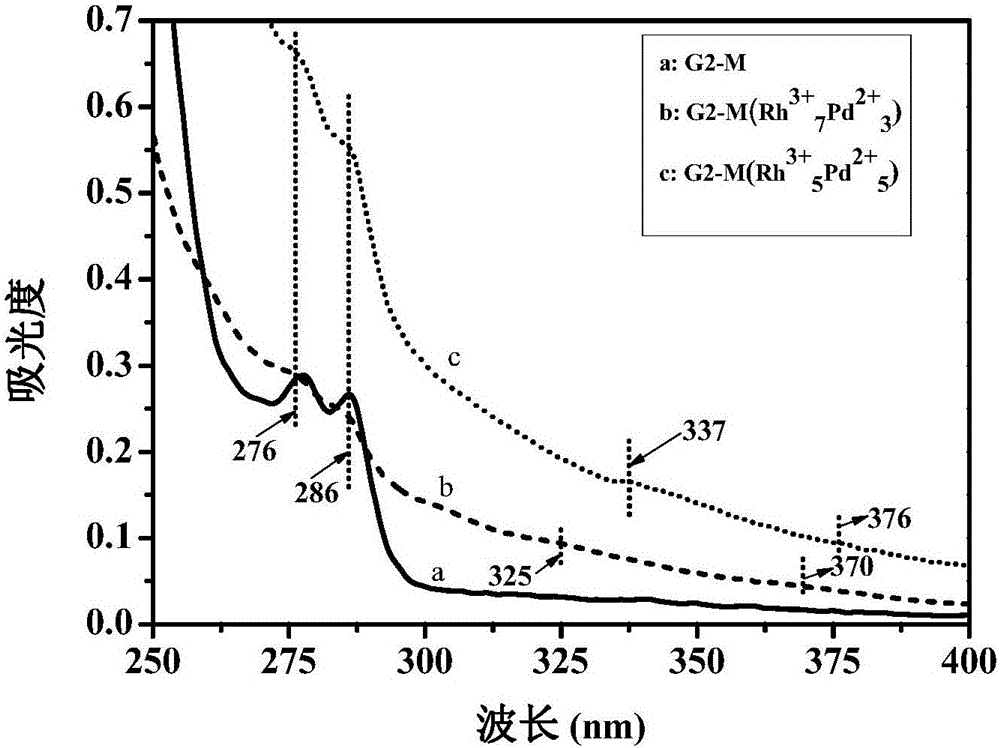

[0064] Such as Picture 1-1 It can be seen that the characteristic peaks of rhodium trichloride and palladium acetate are 403nm and 328nm respectively. G 2 -M(Rh 3+ 70 PD 2 + 30 ) UV absorption spectrum such as Figure 1-3 shown. It can be seen from the figure that G 2 The characteristic absorption peaks of -M are located at 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com