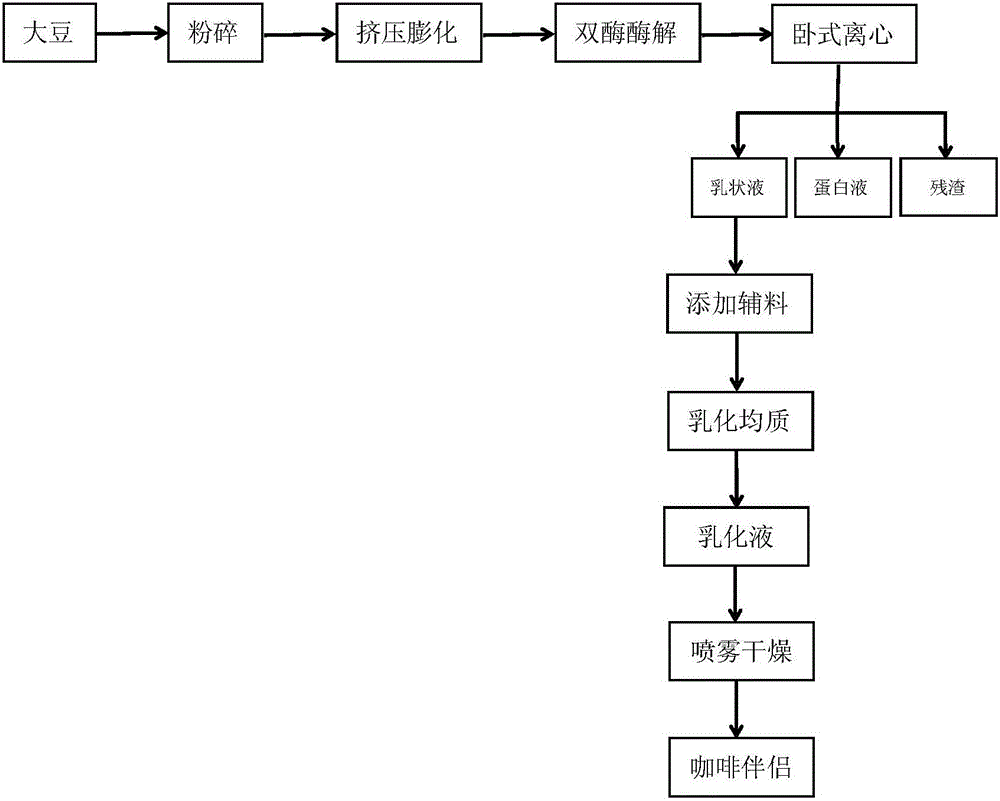

Method for preparing coffee-mate by using aqueous enzymatic emulsion

A technology of coffee mate and emulsion, which is applied in the field of extracting soybean oil emulsion to prepare coffee mate by enzymatic method, which can solve the problems of high cost and cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Clean and compress the fresh soybeans and extrude them with an extruder, then weigh 200g of the crushed puffed material and mix it with 1400ml of water to form a mixed solution in a four-neck bottle reactor, adjust the water bath temperature of the mixed solution to 55°C, and After mixing evenly, adjust the pH value to 8.5 with 1mol / L NaOH, add Protex 6L alkaline protease in an amount of 5‰ of the mixed solution, flavor protease in an amount of 2‰ of the mixed solution, enzymatic hydrolysis for 90 minutes, and During this period, the temperature remains at the initial value. After enzymolysis, use a 90°C water bath to inactivate the enzyme, and centrifuge the enzymolysis solution to obtain protein solution, emulsion and residue. Add 15% β-cyclodextrin and 8% soybean protein isolate to the emulsion, 2% compound emulsifier (sucrose ester and monoglyceride 1:1), 0.2‰ compound antioxidant (TBHQ and BHT compound 1:1), 1‰ sodium caseinate, 70°C constant temperature and high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com