Self-cleaning antibacterial light-cured resin material used for 3D printing

A light-curing resin and 3D printing technology, applied in the direction of additive processing, etc., can solve problems such as adverse effects on human health, restrictions on the promotion of rapid prototyping technology, and poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

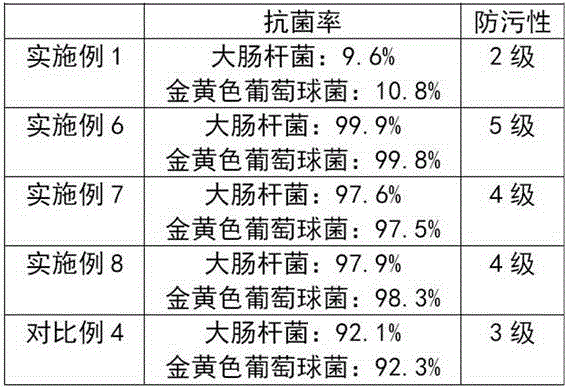

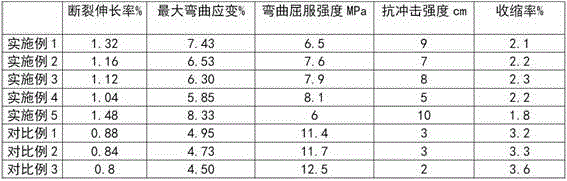

Examples

preparation example Construction

[0016] (1) Preparation of epoxy acrylic resin: Weigh a certain amount of epoxy resin, dissolve it in toluene solvent, stir to dilute the solution, pour it into a three-necked flask, heat and stir in an oil bath at 90°C, and make it Fully dissolve; in addition, accurately measure a certain amount of acrylic acid and place it in a beaker, and add N,N-xylidine and hydroquinone to make an acrylic acid system. In epoxy resin, react stably for 1 hour, then gradually raise the temperature to 95°C, and react for another 1 hour; after the reaction, the product is suction filtered and cooled to room temperature to obtain a light yellow transparent colloidal liquid, namely epoxy acrylic resin; The mass ratio of resin to acrylic acid is 2.5:1, the mass ratio of N,N-xylidine to inhibitor hydroquinone is 1:3, and the mass ratio of N,N-xylidine to epoxy resin is 1 :12.

[0017] (2) Graphene is prepared by the following method: take a certain amount of graphite, treat it in the air at 1000 °...

Embodiment 1

[0022] A photocurable resin material for 3D printing, which consists of the following raw materials in parts by weight: 80 parts of epoxy acrylic resin, 2 parts of reactive diluent, 1 part of photoinitiator, 2 parts of other auxiliary agents, and 3 parts of graphene and 2 parts of multi-walled carbon nanotubes.

[0023] The preparation method of the photocurable resin material used for this 3D printing is as follows:

[0024] (1) Surface treatment of graphene and multi-walled carbon nanotubes with silane coupling agent KH550 or YDH-42 respectively;

[0025] (2) Weigh epoxy acrylic resin, add trimethylolpropane triacrylate, fully stir the system until it is diluted, and adjust the viscosity of the system to about 12 centipoise. Mix evenly; add benzoin dimethyl ether and isopropyl thioxanthone to the solution obtained in step (1), put it in a water bath and heat up to dissolve, and stir thoroughly, until all the solid particles are dissolved, stop stirring, and cool to room tem...

Embodiment 2

[0027] Based on Example 1, the difference is that the weight ratio of the epoxy acrylic resin, graphene and multi-walled carbon nanotubes is 80:5:8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com