Wide-frequency-range wave absorbing material

A wave-absorbing material and wide-frequency domain technology, which is applied in the field of wide-frequency-domain wave-absorbing materials, can solve the problems of narrow frequency band, low efficiency, dielectric parameters and magnetic permeability are difficult to meet the requirements of no reflection, and achieve the effect of high-efficiency absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

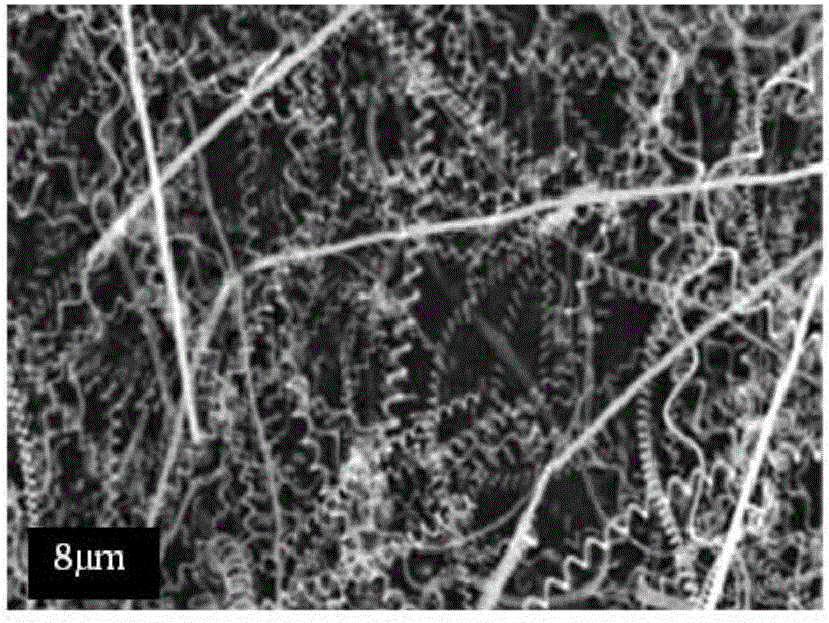

[0033] Refer to attached figure 1 , a wide frequency domain absorbing material, comprising a substrate 1, the substrate 1 has a plurality of micro-carbon coils 2, the micro-carbon coils 2 account for 0.5%-10% of the total weight of the microwave-absorbing material, and the micro-carbon coils 2 have a One or more sizes to achieve the absorption effect of electromagnetic waves in different frequency domains, specifically, the micro-carbon coil 2 has a variety of lengths between 10 microns and 5 mm, and the preferred implementation range is 0.5-3 mm; each micro-carbon The ratio of the helical diameter of the coil 2 to the pitch is between 1:1-5, and the diameter of the carbon filament to the helical diameter is between 1:5-10; particularly, the preferred solution adopted in this embodiment is: the micro-carbon The coil 2 accounts for 1%-3% of the total weight of the absorbing material.

[0034] See attached Figure 2-3 , the morphology of the microcarbon coil 2 under an electro...

Embodiment 2

[0044] Refer to attached Figure 5 , on the basis of the above-mentioned embodiment one, there are also some auxiliary agents in the matrix 1, these auxiliary agents include granular carbon 3 (the granular carbon 3 can be carbon black, graphite powder or obtained by pulverizing the micro-carbon coil of the present invention carbon powder), rod-shaped carbon 4 (the rod-shaped carbon 4 can be nano-carbon rods, vapor-phase grown straight carbon fibers), aluminum fragments 5 and ferrite 6, and the respective additions of these auxiliary agents account for 0.1%- 8%, wherein ferrite 6 is generally added in an amount of 5% of the weight of the wave-absorbing material, and the addition of other auxiliary agents (granular carbon 3, rod-shaped carbon 4, aluminum fragments 5) is preferably 1%.

[0045] With the addition of the above components, the ferrite increases the inductance L and increases the magnetic loss; the carbon powder and carbon rod affect the resistance R due to overlappi...

Embodiment 3

[0048] Refer to attached Figure 6 , on the basis of the first embodiment above, the substrate 1 is in the shape of a thin sheet, and its bottom surface is provided with a metal layer 7, the metal layer 7 will reflect electromagnetic waves, so that the electromagnetic waves that will pass through the substrate 1 will be reflected back to the micro carbon coil 2 and other auxiliary materials. agent for secondary, three or even multiple times of absorption; when the absorbing material of this embodiment is attached to the surface of an electronic instrument, it will firstly effectively reduce the residual electromagnetic wave back to the atmosphere, and secondly prevent the residual electromagnetic wave from passing through the absorbing material Access to electronic equipment. Similarly, a metal layer can also be provided on the basis of the second embodiment, which will not be described in detail here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com