Construction method of shield excavation-type air-pushed tunnel through ground fissures

A technology for tunnel construction and ground fissures, applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of difficult construction, high safety risks, and increased costs, and achieve low construction costs, simple method steps, and easy construction easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] Such as figure 1 A shield excavation type air-push tunnel construction method through ground fissures is shown, comprising the following steps:

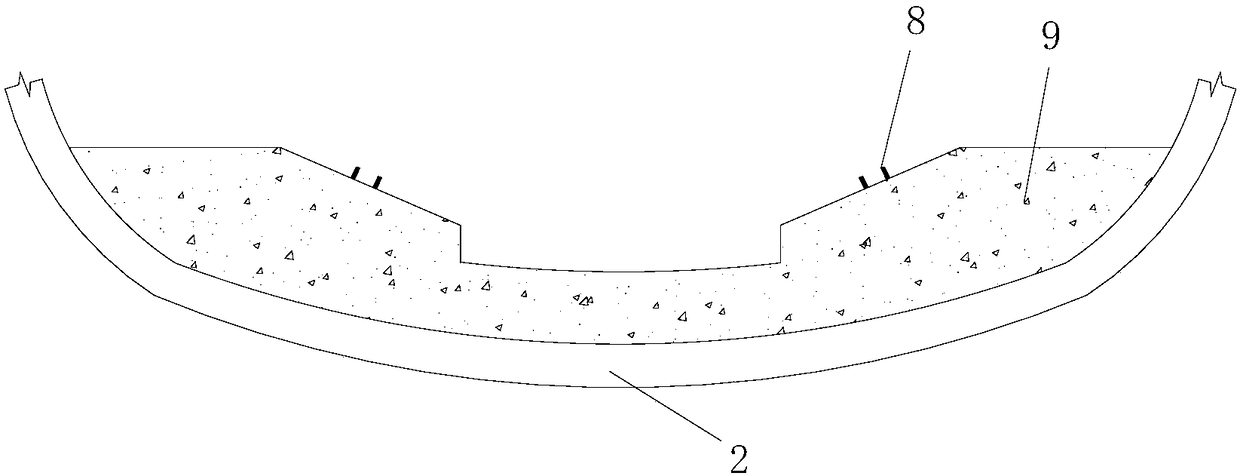

[0073] Step 1. Concrete guide platform construction in the ground fissure underground excavation tunnel: After the construction of the inverted arch 2 of the ground fissure underground excavation tunnel 1 is completed, the inverted arch 2 is backfilled to obtain the inverted arch backfill structure;

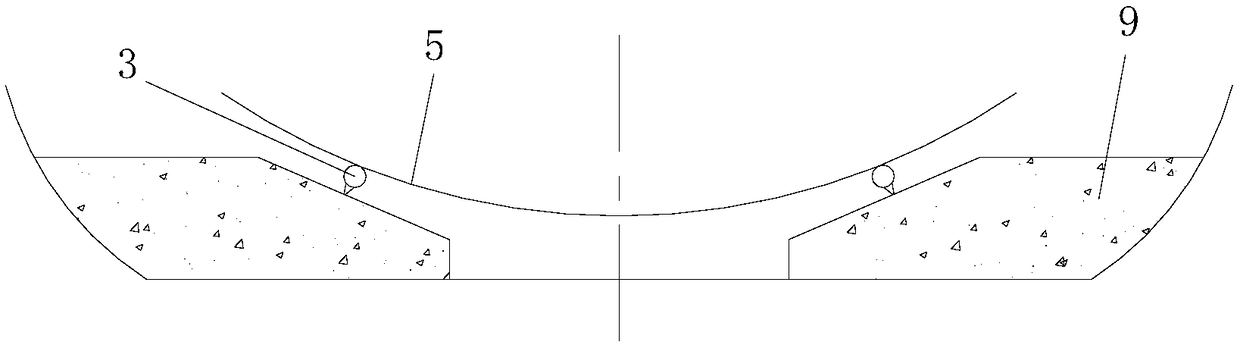

[0074] The backfill structure of the inverted arch is a concrete guide platform 9, and a push channel for the shield machine to push forward is provided in the middle of it. The concrete guide platform 9 is arranged along the longitudinal length of the ground fissure underground tunnel 1, see figure 2 ;

[0075] Step 2. Construction of guide rails and counterforce frames: Install a guide rail 3 on the left and right sides of the concrete guide platform 9 described in step 1 for the shield machine to push forward, and the two gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com