Steel-rubber concrete combined bridge beam slab

A rubber concrete and combined technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as fatigue damage of concrete beams and slabs, fatigue fracture of shear connectors, etc., to avoid concrete fatigue damage, prevent fatigue damage, Realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

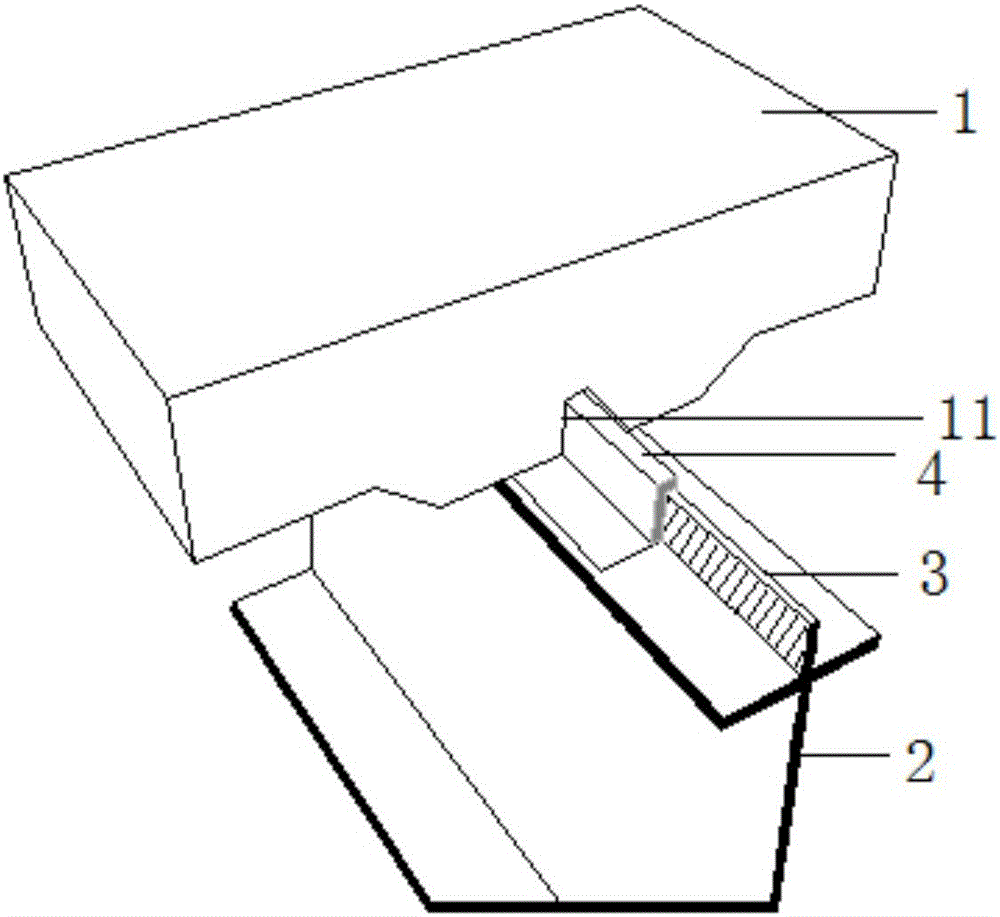

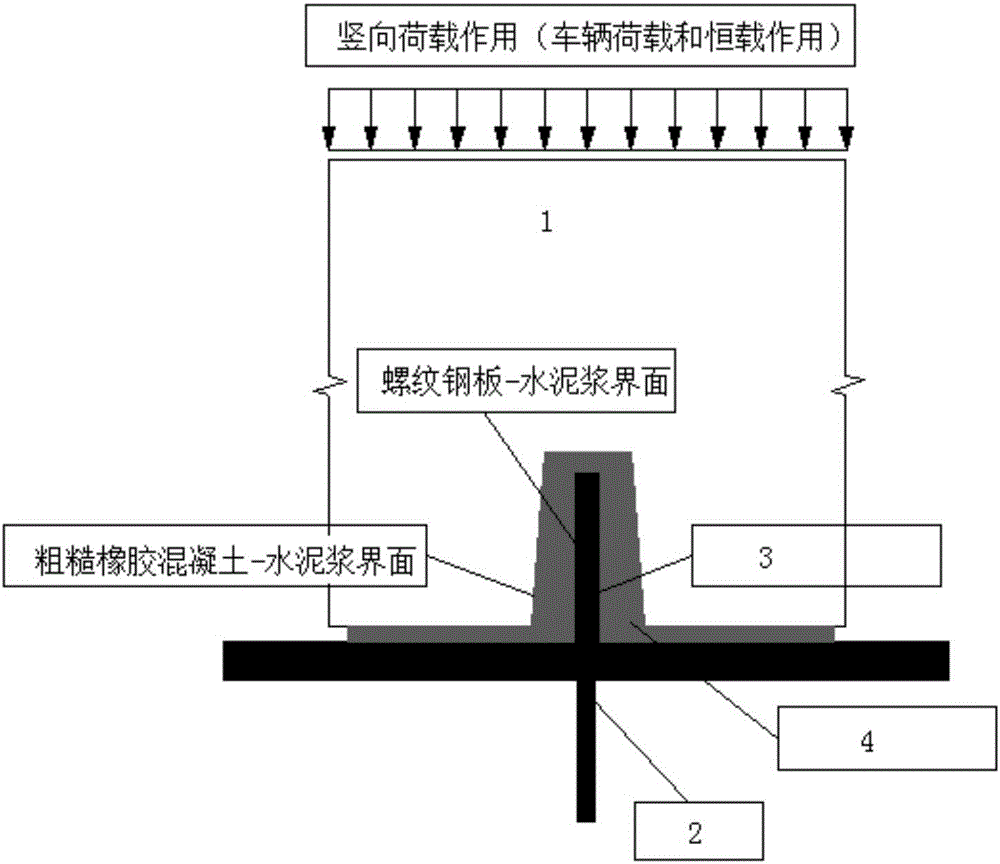

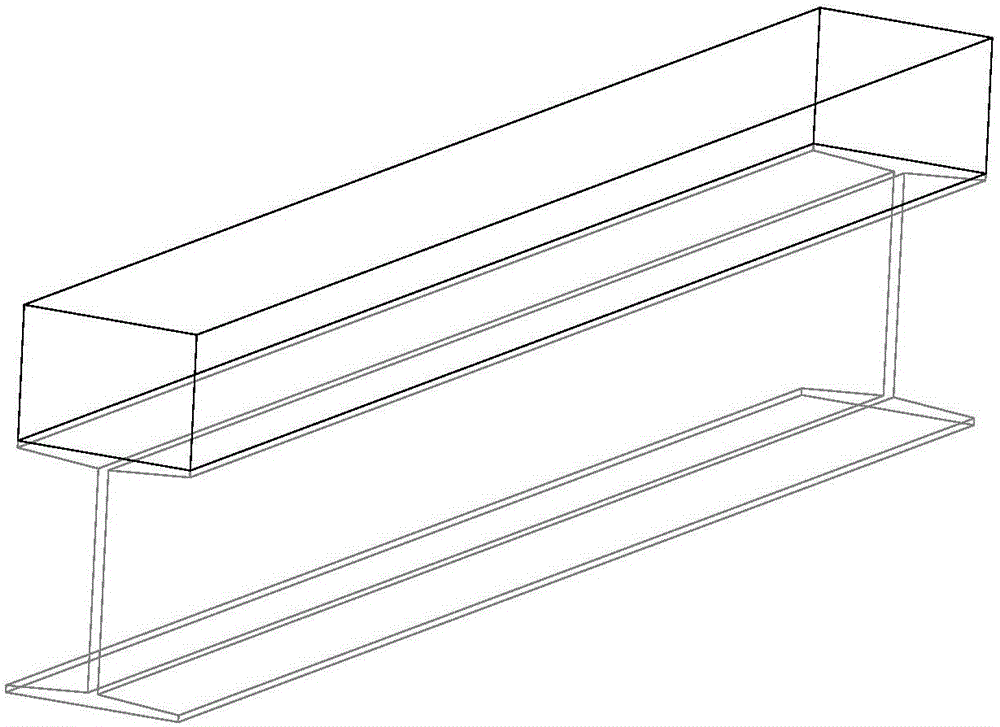

[0025] refer to Figure 1 to Figure 3 , a steel-rubber concrete combined bridge beam slab, comprising an upper prefabricated slab 1 and a lower I-shaped steel girder 2, the upper prefabricated slab 1 is prepared by mixing concrete and rubber powder, and the rubber powder accounts for 10% of the total volume of the two ~40%, and the bottom of the upper prefabricated slab 1 is provided with an inwardly depressed longitudinal rib-shaped groove 11; the top of the lower I-shaped steel beam 2 is welded with a threaded steel plate 3, the The longitudinal rib-shaped groove 11 fits with the threaded steel plate 3, and the gap between the longitudinal rib-shaped groove 11 and the threaded steel plate 3 is filled with rubber concrete grout 4.

[0026] The rubber concrete layer between the upper prefabricated slab 1 and the lower I-shaped steel beam 2 is sandblasted.

[0027] Such as figure 2 As shown, in the composite beam, there are mainly two contact surfaces: the bonded surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com