Preparation method of copper-free click crosslinking polysaccharide microspheres

A polysaccharide and microsphere technology, used in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of loss of sustained release ability of microspheres, poor stability of polysaccharide microspheres, protein denaturation, etc., to ensure cell compatibility. safety, low cost of raw materials, and low cross-linking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

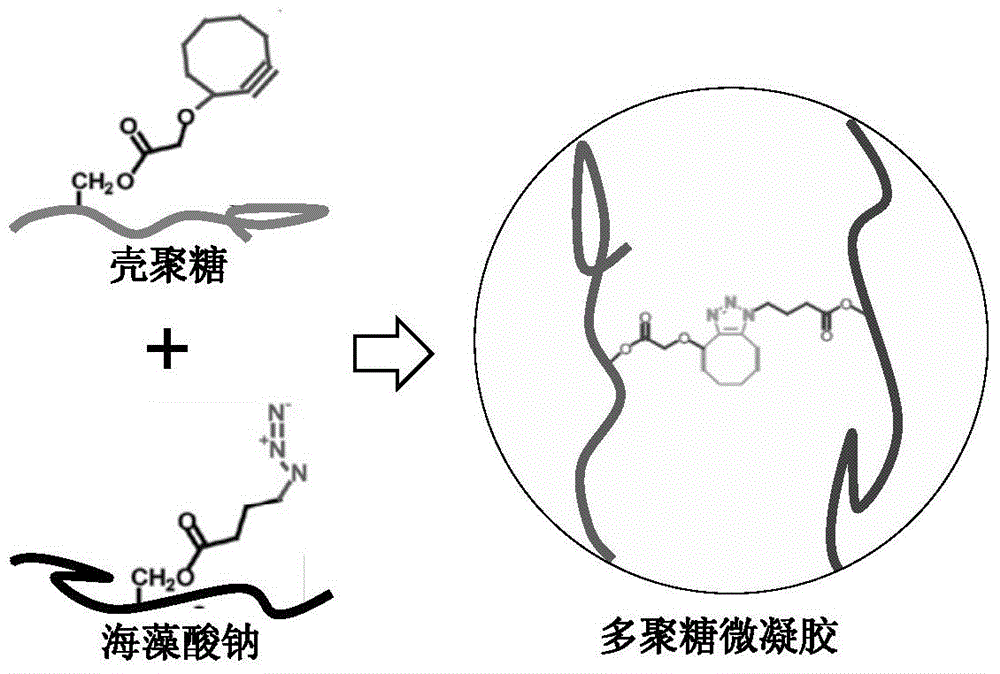

[0033] The preparation method of copper-free click-crosslinked polysaccharide microspheres of the present invention uses chitosan and sodium alginate as matrix materials, and is formed by biocompatible click-crosslinking, specifically comprising the following steps:

[0034] Step 1, dissolving chitosan and 1-hydroxybenzotriazole in water at room temperature, the chitosan and 1-hydroxybenzotriazole are in an equal mass ratio, and the mass concentrations of both are 0.05 to 0.15% ;

[0035] Step 2. Dissolve cyclooctyne-3-glycolic acid in a mixed solvent of tetrahydrofuran / water at room temperature, the volume ratio of tetrahydrofuran to water in the mixed solvent of tetrahydrofuran / water is 1:3, cyclooctyne-3 - the mass concentration of glycolic acid is 0.5-1%;

[0036] Step 3. At room temperature, mix the two solutions obtained in step 1 and step 2 according to the volume ratio of 1:1, then add diisopropylethylamine, the mass concentration of diisopropylethylamine is 0.05-0.2%...

Embodiment 1

[0049] The specific operation steps are:

[0050] (1) 0.05 gram of chitosan and 0.05 gram of 1-hydroxybenzotriazole are dissolved in 100 milliliters of water at room temperature;

[0051] (2) Dissolve 0.5 g of cyclooctyne-3-glycolic acid in a mixed solvent of 100 ml of tetrahydrofuran / water (volume ratio 1:3) at room temperature;

[0052] (3) Fully mix the two solutions obtained in (1) and (2) at room temperature, add 0.1 g of diisopropylethylamine, stir and react at 0°C for 10 hours, dialyze for 2 days and freeze-dry to obtain cyclooctyne Chitosan (structural schematic diagram see figure 1 );

[0053] (4) Dissolve 0.2 g of sodium alginate and 0.2 g of water-soluble carbodiimide in 100 ml of water at room temperature, then add 0.2 ml of 11-azido-3,6,9-triethylether-1-amine, and stir at room temperature Reacted for 22 hours, lyophilized after 2 days of dialysis to obtain sodium azide alginate (see figure 1 );

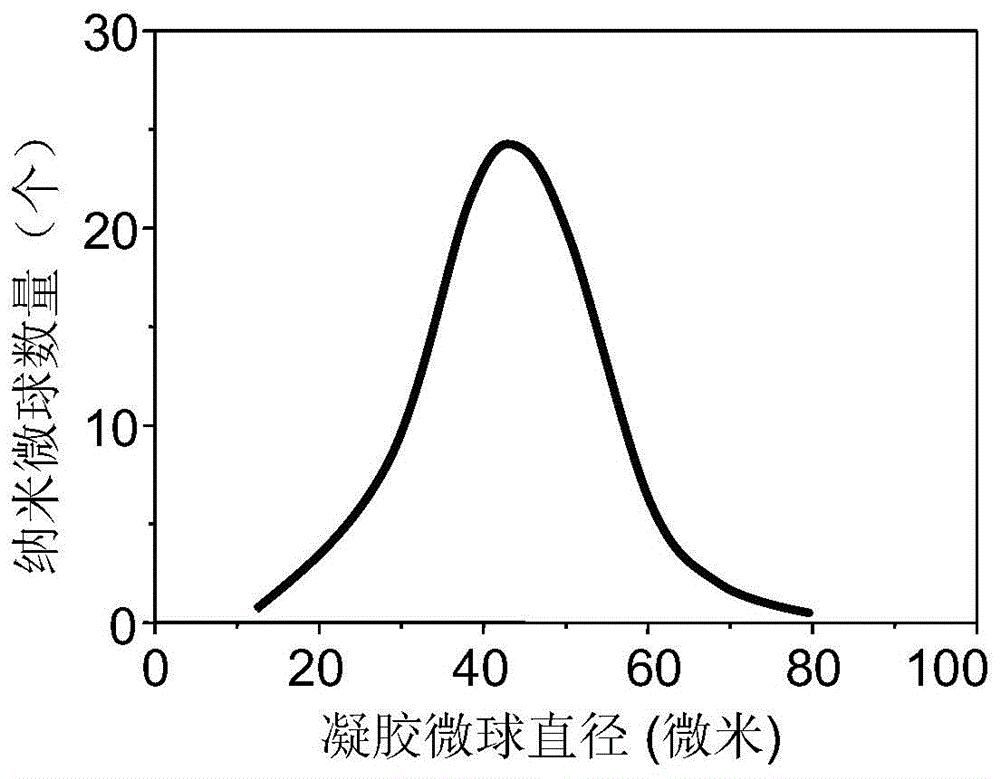

[0054] (5) Prepare respectively cyclooctynylated chitosan aque...

Embodiment 2

[0060] The specific operation steps are:

[0061] (1) 0.08 gram of chitosan and 0.08 gram of 1-hydroxybenzotriazole are dissolved in 100 milliliters of water at room temperature;

[0062] (2) Dissolve 0.6 g of cyclooctyne-3-glycolic acid in a mixed solvent of 100 ml of tetrahydrofuran / water (volume ratio 1:3) at room temperature;

[0063] (3) Fully mix the two solutions obtained in (1) and (2) at room temperature, add 0.15 g of diisopropylethylamine, stir and react at 0°C for 11 hours, dialyze for 2 days and freeze-dry to obtain cyclooctyne Chitosan;

[0064] (4) Dissolve 0.2 g of sodium alginate and 0.5 g of water-soluble carbodiimide in 100 ml of water at room temperature, then add 0.35 ml of 11-azido-3,6,9-triethylether-1-amine, and stir at room temperature React for 23 hours, lyophilize after 2 days of dialysis to obtain sodium alginate azide;

[0065] (5) Prepare respectively cyclooctynylated chitosan aqueous solution and azide sodium alginate aqueous solution with a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com