A high-frequency high-speed PCB and its manufacturing method

A production method and high-speed technology, applied to printed circuit components, circuit substrate materials, etc., can solve problems such as easy peeling off of solder mask, achieve the effects of improving production efficiency and product quality, improving rigidity, and avoiding waste of manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

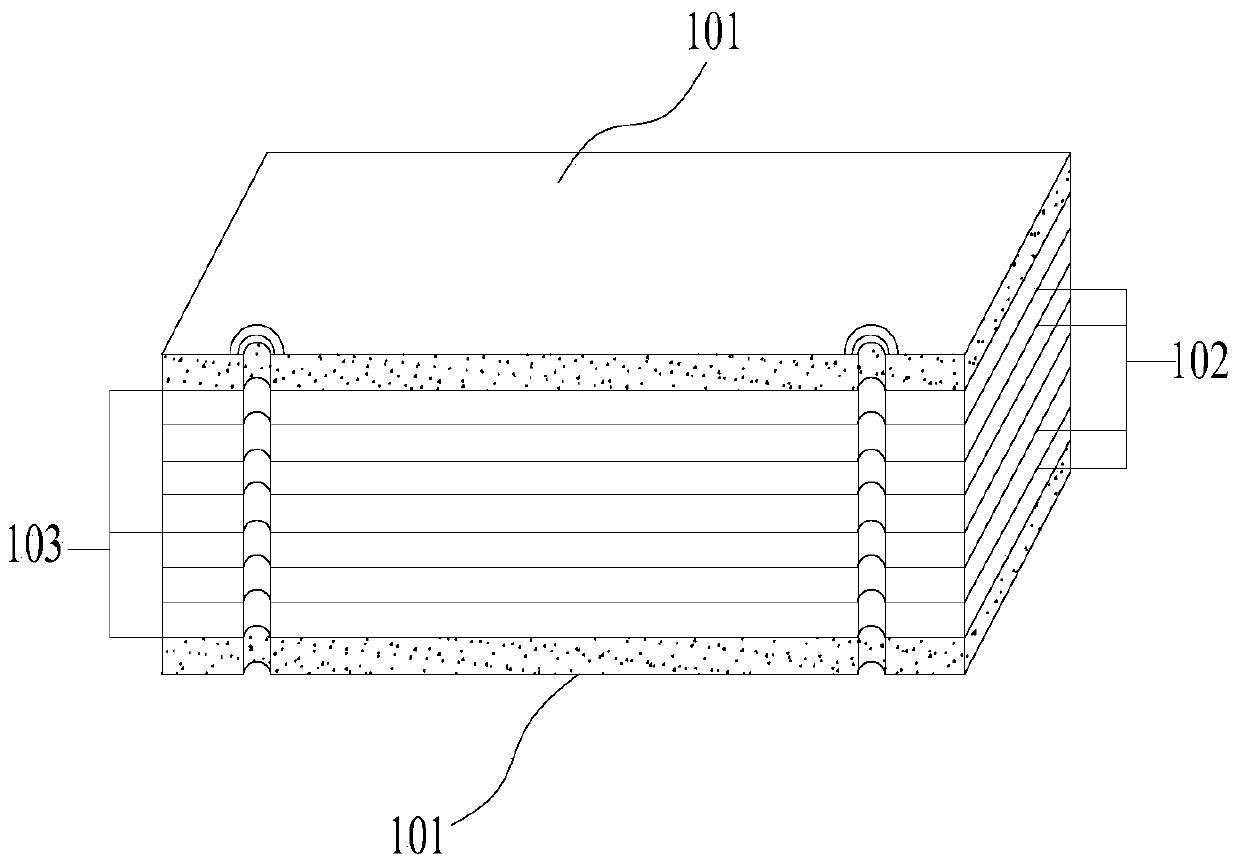

[0036] A high-frequency and high-speed PCB according to the present invention includes at least two layers of rigid base material core boards, at least one layer of PTFE base material core boards and at least one layer of FR4 base material core boards, according to the rigid base material core boards from bottom to top , PTFE base material core board, FR4 base material core board, PTFE base material core board, and rigid base material core board are stacked in sequence, and PTFE type prepregs are pressed between each core board; the main body of the PCB board There are through holes penetrating through the rigid substrate core board, PTFE base material core board and FR4 base material core board.

[0037] The rigid base material core plate adopted in the present invention is a rigid low-loss base material core plate; in a further solution, the low-loss rigid base material of the present invention is a rigid material with slightly worse electrical properties than PTFE, that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com