Bulk heterojunction perovskite solar cell and preparation method thereof

A solar cell, bulk heterojunction technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as unfavorable battery production and application, deterioration of battery performance, photogenerated electron leakage, etc., to simplify the structure and Preparation process, reduce production cost, high performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

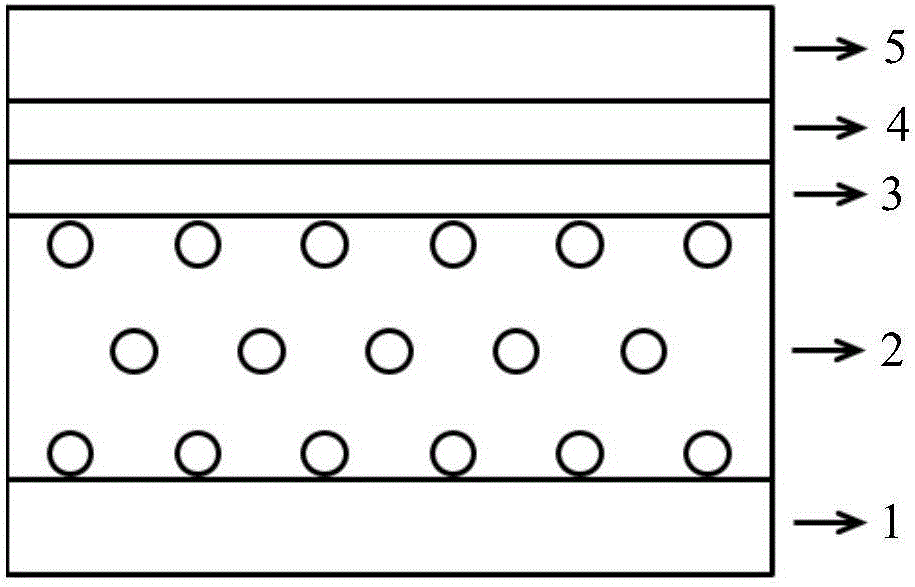

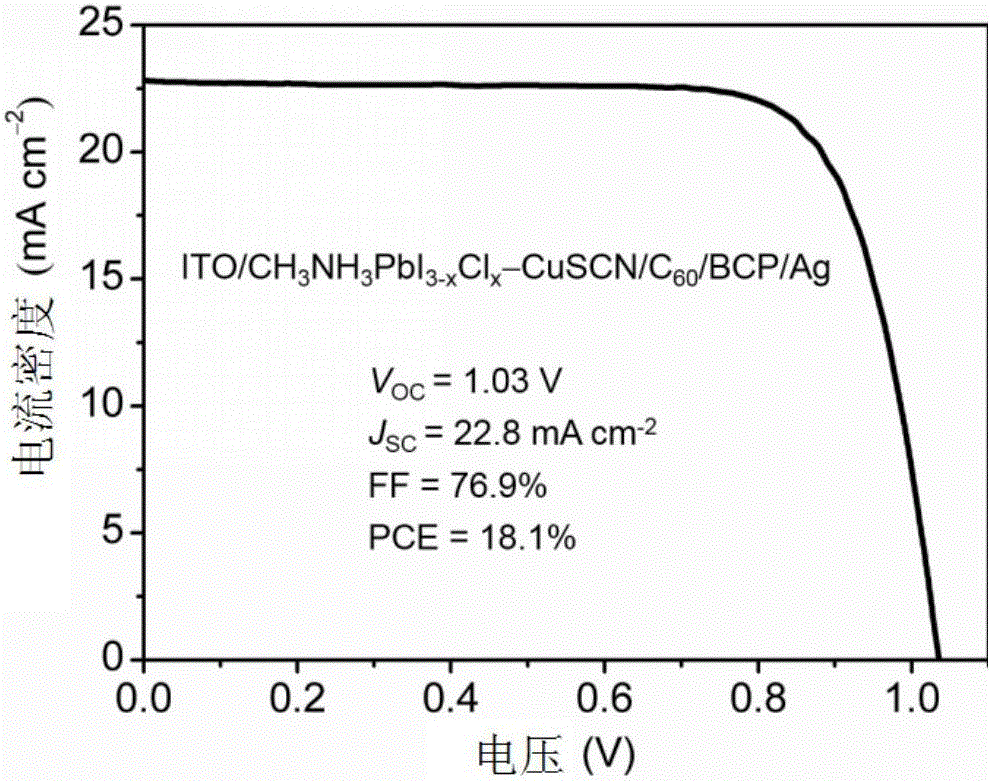

[0027] This embodiment is a perovskite-CuSCN bulk heterojunction solar cell with a reverse structure, and its structure is: ITO / CH 3 NH 3 PbI 3-x Cl x -CuSCN / C 60 / BCP / Ag.

[0028] Configure CH in the nitrogen glove box 3 NH 3 PbI 3-x Cl x (0≤x≤3) and CuSCN mixed precursor solution, 7.419g PbI 2 , 0.448g PbCl 2 , 2.815g CH 3 NH 3 I and 0.150 g CuSCN were dissolved in 15.0 mL N,N-dimethylformamide (DMF), and stirred overnight to completely dissolve.

[0029] The ITO conductive glass substrate was ultrasonically cleaned with an aqueous solution of decontamination powder, deionized water, acetone, and absolute ethanol for 20 minutes, and finally dried with nitrogen.

[0030] In a nitrogen glove box, spin-coated the above precursor solution on the ITO substrate at 5000rpm for 30s, and after spin coating for about 5s, quickly add about 200μL of chlorobenzene to the ITO substrate, and finally 70% in DMF atmosphere. Anneal at ℃ for 10 minutes.

[0031] The prepared ITO / CH 3 NH 3 PbI 3-x Cl x...

Embodiment 2

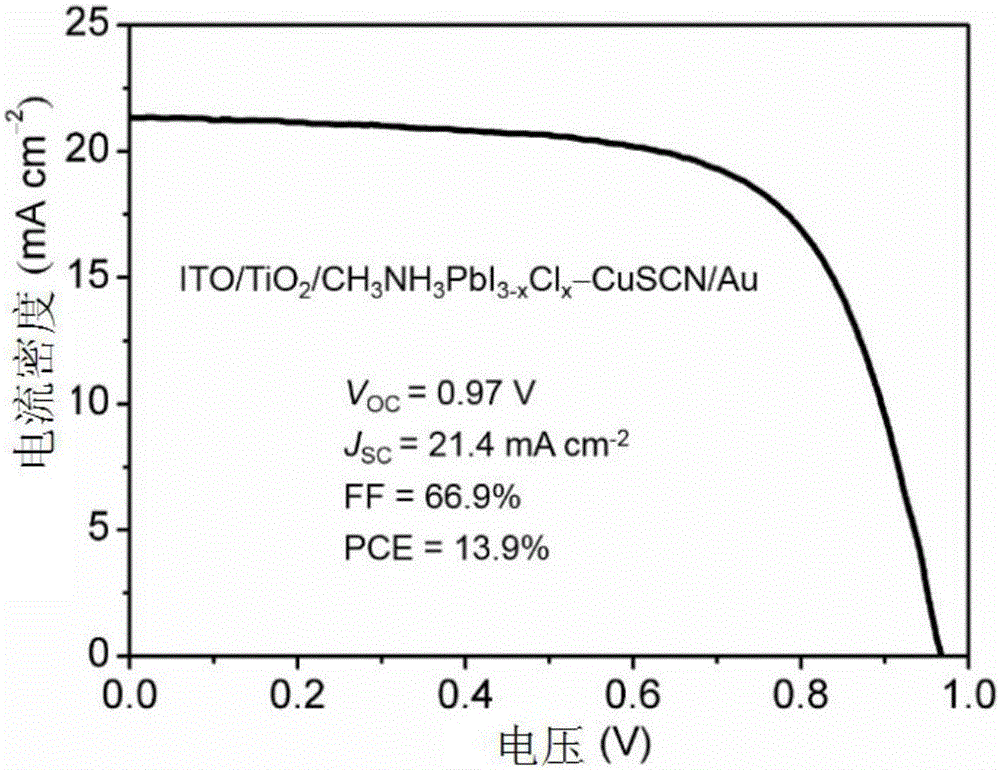

[0034] This embodiment is a perovskite-CuSCN bulk heterojunction solar cell with a forward structure, and its structure is: ITO / TiO 2 / CH 3 NH 3 PbI 3-x Cl x -CuSCN / Au.

[0035] Configure TiO in atmospheric environment 2 For precursor solution, dissolve 125μL of concentrated nitric acid in 2.5mL of absolute ethanol, then add 470μL of tetraisopropyl titanate dropwise, stir at room temperature for 2 hours, then add 115μL of deionized water and stir overnight, and finally add 9.63mL of n-propyl Alcohol is diluted.

[0036] CH 3 NH 3 PbI 3-x Cl x The configuration of the mixed precursor solution of (0≤x≤3) and CuSCN is exactly the same as in Example 1.

[0037] The pretreatment of the ITO conductive glass substrate is exactly the same as in Example 1.

[0038] In the atmosphere, spin-coated TiO on the ITO substrate 2 The precursor solution was annealed at 200°C for 1 hour at a rotation speed of 3000 rpm for 30 seconds.

[0039] In the nitrogen glove box, in the prepared ITO / TiO 2 Spin coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com