Lorentz force based novel polymer solar cell preparation method

A technology of solar cells and polymers, applied in nanotechnology, circuits, and photovoltaic power generation for materials and surface science, can solve problems such as low photoelectric conversion efficiency, easy electron recombination, and limited photosensitive layer thickness, so as to improve photoelectricity. Conversion efficiency, increased thickness, and reduced composite effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the examples, but the present invention is not limited.

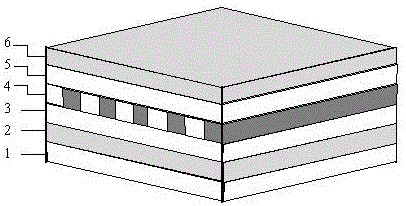

[0009] like figure 1 As shown, the glass substrate with indium tin oxide (ITO) was cleaned with N 2 The distilled water on the surface of the ITO was blown dry and dried in an oven at 60 °C. Spin-coat a layer of high molecular polymer PEDOT:PSS hole transport layer on the cleaned ITO glass surface. PEDOT:PSS was first filtered through a 0.45 µm aqueous membrane and then spin-coated. The rotation speed of the spin coating is 3000 rpm, and the time is 20s to form a hole transport layer.

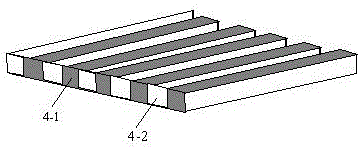

[0010] A layer of 50 nm NdFeB magnetic material is grown in a strong magnetic field, coated with a layer of photoresist, exposed with a mask plate with a strip pattern, and then developed, and the magnetic material layer is etched by wet etching Etching, and finally removing glue to form a strip pattern of magnetic material, the strip direction is perpen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com