Cold-resistant, twist-resistant, flame-retardant foam coating glue for textiles and its treatment method

A foam coating, anti-distortion technology, used in textiles, papermaking, fiber processing, etc., can solve the problems of flame retardant textile melting, etc., and achieve good low temperature resistance, good flame retardant melting resistance, and good thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

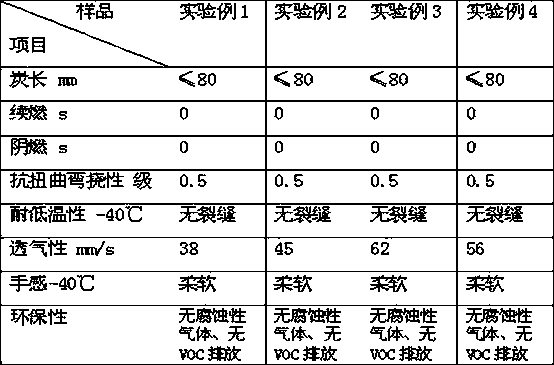

Examples

Embodiment 1

[0034]Cold-resistant, twist-resistant, flame-retardant foam coating glue, raw material weight ratio:

[0035] Mix soft elastic foam coating glue 80, blocked isocyanate crosslinking agent 2, and high-permeability softener 1, and then add crystalline type II ammonium polyphosphate 20, expanded graphite 10, and polytetrafluoroethylene micropowder 4. The high-speed stirring of the machine makes the material fully mixed into the air to reach the foaming state, and the volume of the mixed material is increased by 1-1.5 times, and the coating glue is obtained.

[0036] Cold-resistant, twist-resistant, flame-retardant foam coating treatment method:

[0037] (1) Fabric pre-calendering treatment, pressure 9 Mpa, temperature 60 ℃, speed 20m / min;

[0038] (2) Use the coating glue prepared by the above method to coat the fabric, and bake at 150°C-155°C-155°C-160°C for 2 minutes.

Embodiment 2

[0040] Cold-resistant, twist-resistant, flame-retardant foam coating glue, raw material weight ratio:

[0041] Mix flexible elastic foam coating glue 88, blocked isocyanate crosslinking agent 2.5, high penetration softener 2, mix and stir evenly, then add crystal type II ammonium polyphosphate 22, expanded graphite 12, polytetrafluoroethylene micropowder 5, use dispersion The high-speed stirring of the machine makes the material fully mixed into the air to reach the foaming state, and the volume of the mixed material is increased by 1.5-2 times to obtain a coating glue.

[0042] Cold-resistant, twist-resistant, flame-retardant foam coating treatment method:

[0043] (1) Fabric pre-calendering treatment, pressure 9 Mpa, temperature 70 ℃, speed 15m / min;

[0044] (2) Use the coating glue prepared by the above method to coat the fabric, and bake at 150°C-155°C-155°C-160°C for 2.5 minutes.

Embodiment 3

[0046] Cold-resistant, twist-resistant, flame-retardant foam coating glue, raw material weight ratio:

[0047] Mix flexible elastic foam coating glue 95, blocked isocyanate crosslinking agent 3, high penetration softener 2.5, mix and stir evenly, then add crystal type II ammonium polyphosphate 24, expanded graphite 13, polytetrafluoroethylene micropowder 5.5, use dispersion The high-speed stirring of the machine makes the material fully mixed into the air to reach the foaming state, and the volume of the mixed material is increased by 2-2.5 times to obtain a coating glue.

[0048] Cold-resistant, twist-resistant, flame-retardant foam coating treatment method:

[0049] (1) Fabric pre-calendering treatment, pressure 10 Mpa, temperature 65 ℃, speed 25m / min;

[0050] (2) Use the coating glue prepared by the above method to coat the fabric, and bake at 150°C-155°C-155°C-160°C for 3 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com