A kind of aluminum-plastic composite film with oxidation resistance and high ductility and preparation method thereof

An aluminum-plastic composite film, anti-oxidation technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., to achieve the effect of improving performance, improving corrosion resistance and oxidation resistance, and easy adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

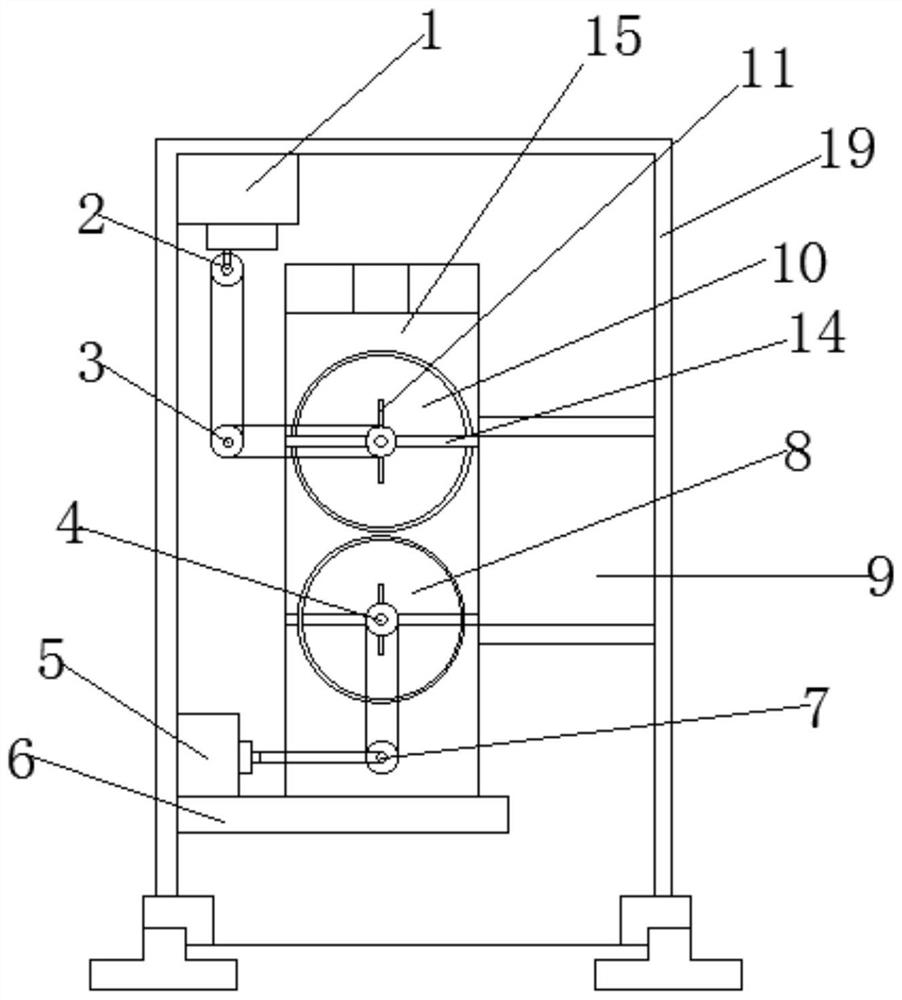

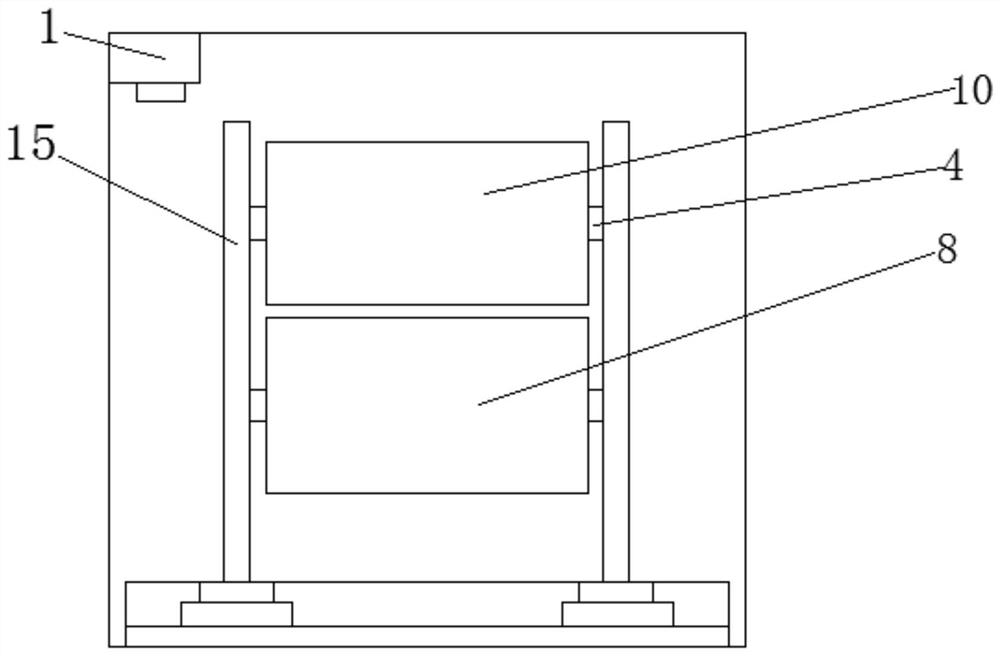

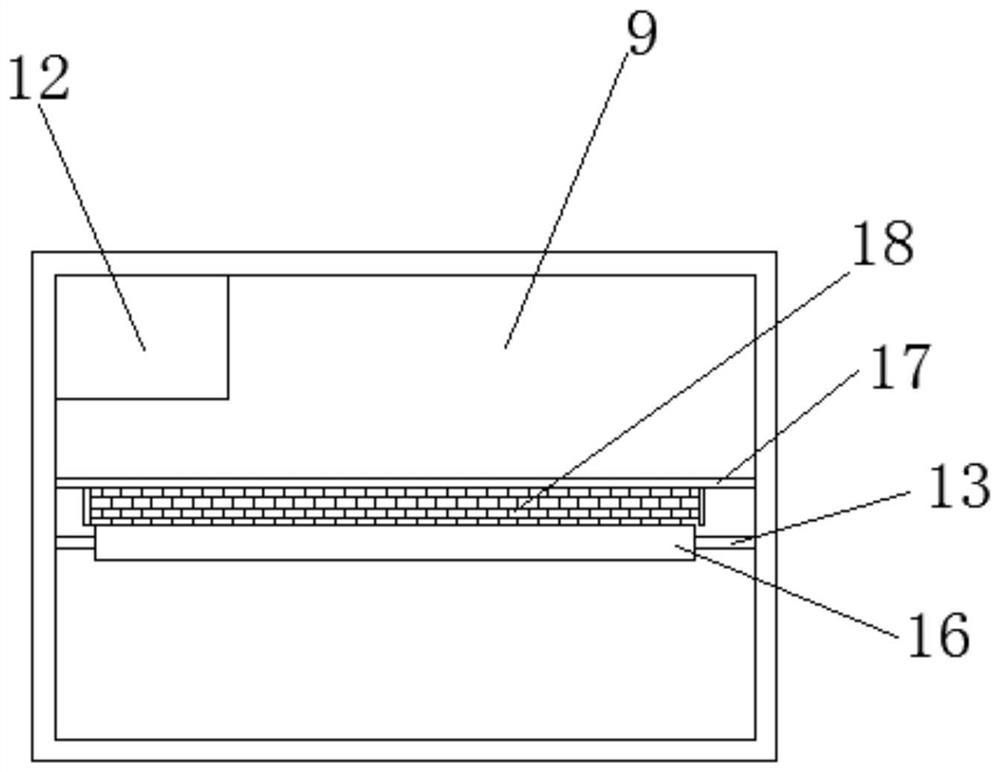

[0043] see Figure 1-3As shown, an aluminum-plastic composite film with anti-oxidation and high ductility is composed of a nylon composite layer, an aluminum foil composite layer, and a polypropylene layer from the outside to the inside; the nylon composite layer is the upper and lower surfaces of the nylon layer. It is obtained by coating nano-scale silicon dioxide; the aluminum foil composite layer is obtained by coating nano-scale titanium dioxide on the upper and lower surfaces of the aluminum foil layer; the aluminum foil layer is obtained by rolling aluminum alloy;

[0044] The preparation of the aluminum foil layer comprises the following steps:

[0045] S1, prepare the aluminum alloy raw material, the aluminum alloy raw material is made up of base material, auxiliary material and additive, base material is 90.59% aluminum by mass percentage; auxiliary material is 6.2% zinc by mass percentage; additive is by mass percentage 0.32% silicon, 0.55% manganese, 1.15% iron, 0...

Embodiment 2

[0061] see Figure 1-3 As shown, an aluminum-plastic composite film with anti-oxidation and high ductility is characterized in that: the aluminum-plastic composite film is sequentially composed of a nylon composite layer, an aluminum foil composite layer, and a polypropylene layer from the outside to the inside; the nylon composite layer is The upper and lower surfaces of the nylon layer are coated with nano-scale silicon dioxide; the aluminum foil composite layer is obtained by coating the upper and lower surfaces of the aluminum foil layer with nano-scale titanium dioxide; the aluminum foil layer is obtained by rolling aluminum alloy;

[0062] The preparation of the aluminum foil layer comprises the following steps:

[0063] S1, prepare the aluminum alloy raw material, the aluminum alloy raw material is made up of base material, auxiliary material and additive, base material is 90.24% aluminum by mass percentage; auxiliary material is 6.3% zinc by mass percentage; additive i...

Embodiment 3

[0078] see Figure 1-3 As shown, an aluminum-plastic composite film with anti-oxidation and high ductility is characterized in that: the aluminum-plastic composite film is sequentially composed of a nylon composite layer, an aluminum foil composite layer, and a polypropylene layer from the outside to the inside; the nylon composite layer is The upper and lower surfaces of the nylon layer are coated with nano-scale silicon dioxide; the aluminum foil composite layer is obtained by coating the upper and lower surfaces of the aluminum foil layer with nano-scale titanium dioxide; the aluminum foil layer is obtained by rolling aluminum alloy;

[0079] The preparation of the aluminum foil layer comprises the following steps:

[0080] S1, prepare aluminum alloy raw material, aluminum alloy raw material is made up of base material, auxiliary material and additive, base material is 88.81% aluminum by mass percentage; auxiliary material is 7.4% zinc by mass percentage; additive is calcul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com