High-elasticity flame retardant polyester

A flame-retardant polyester and high-elasticity technology, applied in the field of high-elasticity and flame-retardant polyester, can solve the problems of poor air permeability and poor absorption, and achieve the effects of increased viscoelasticity, good compatibility and good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

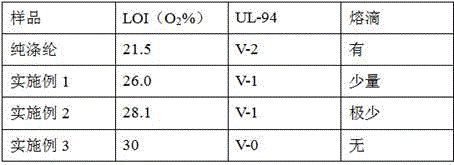

Examples

Embodiment 1

[0021] A high-elastic flame-retardant polyester, which is made of 5 parts by weight of polyethylene glycol, 10 parts of purified terephthalic acid, 10 parts of bamboo fiber, 5 parts of phosphate starch, 5 parts of diatom mud, 30 parts of polyester PET And 30 parts of polyester PTT made.

[0022] Its preparation process is as follows:

[0023] (1) Put polyethylene glycol, terephthalic acid and phosphate starch into the reaction kettle according to the ratio, raise the temperature to 160°C, keep the temperature for 2 hours, then continue to heat up to 190°C, keep the heat for 2 hours, and finally the vacuum degree is - React for 3 hours under the conditions of 0.95MPa and 230°C to obtain a mixed solution;

[0024] (2) Weave plant fibers into single-ply yarns with a diameter of 1.5mm, and cut them transversely into fiber segments with a length of 1mm;

[0025] (3) Soak the fiber segment obtained in step (2) in the mixed solution obtained in step (1) for 100 minutes to obtain th...

Embodiment 2

[0029] A high-elastic flame-retardant polyester, which is made of 8 parts by weight of polyethylene glycol, 20 parts of purified terephthalic acid, 12 parts of soybean fiber, 12 parts of phosphate starch, 12 parts of diatom mud, 38 parts of polyester PET and 20 parts of polyester PTT.

[0030] Its preparation process is as follows:

[0031] (1) Put polyethylene glycol, terephthalic acid and phosphate starch into the reaction kettle according to the ratio, raise the temperature to 165°C, keep the temperature for 2 hours, then continue to heat up to 195°C, keep the temperature for 2 hours, and finally the vacuum degree is - React for 3 hours under the conditions of 0.95MPa and 215°C to obtain a mixed solution;

[0032] (2) Weave plant fibers into single-ply yarns with a diameter of 2mm, and cut them transversely into fiber segments with a length of 2mm;

[0033] (3) Soak the fiber segment obtained in step (2) in the mixed solution obtained in step (1) for 100 minutes to obtain...

Embodiment 3

[0037] A high-elastic flame-retardant polyester, which is composed of 15 parts by weight of polyethylene glycol, 30 parts of purified terephthalic acid, 25 parts of wood fiber, 15 parts of phosphate starch, 15 parts of diatom mud, 50 parts of polyester PET And 25 parts of polyester PTT made.

[0038] Its preparation process is as follows:

[0039] (1) Put polyethylene glycol, terephthalic acid and phosphate starch into the reaction kettle according to the ratio, raise the temperature to 170°C, keep the temperature for 2 hours, then continue to heat up to 210°C, keep the heat for 2 hours, and finally the vacuum degree is - React for 3 hours under the conditions of 0.95MPa and 210°C to obtain a mixed solution;

[0040] (2) Weave the plant fiber into a single-ply yarn with a diameter of 3 mm, and cut it transversely into fiber segments with a length of 1 mm;

[0041] (3) Soak the fiber segment obtained in step (2) in the mixed solution obtained in step (1) for 100 minutes to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com