Graphene/polyolefin plastic composite food packaging film and preparation method thereof

A technology for compounding food and packaging films, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of human health threats, lack of understanding of the impact, etc., and achieve excellent mechanical properties, excellent mechanical properties, and the effect of inhibiting migration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Graphene and low-density polyethylene (LDPE) are mixed evenly, and the graphene mass percentage content is 0.05%, 0.2% and 1% respectively, and the mixed material is sent into a twin-screw extruder, and the material is in the shear of the screw. Fully blended under cutting, mixing and conveying, and finally extruded and granulated through the die. This granulation process was repeated twice.

[0033] Twin-screw extruder parameter setting: the temperature of barrel zone 1 to zone 9 is: 150°C, 155°C, 155°C, 160°C, 160°C, 165°C, 165°C, 165°C, 165°C; die head temperature The temperature is 165°C; the screw speed is 150r / min.

[0034] Send the prepared masterbatch into the film blowing machine, and use the method of hollow blow molding to obtain the corresponding film. The temperature of Zone 1-4 of the film blowing machine is 155°C, 160°C, 165°C, 165°C respectively.

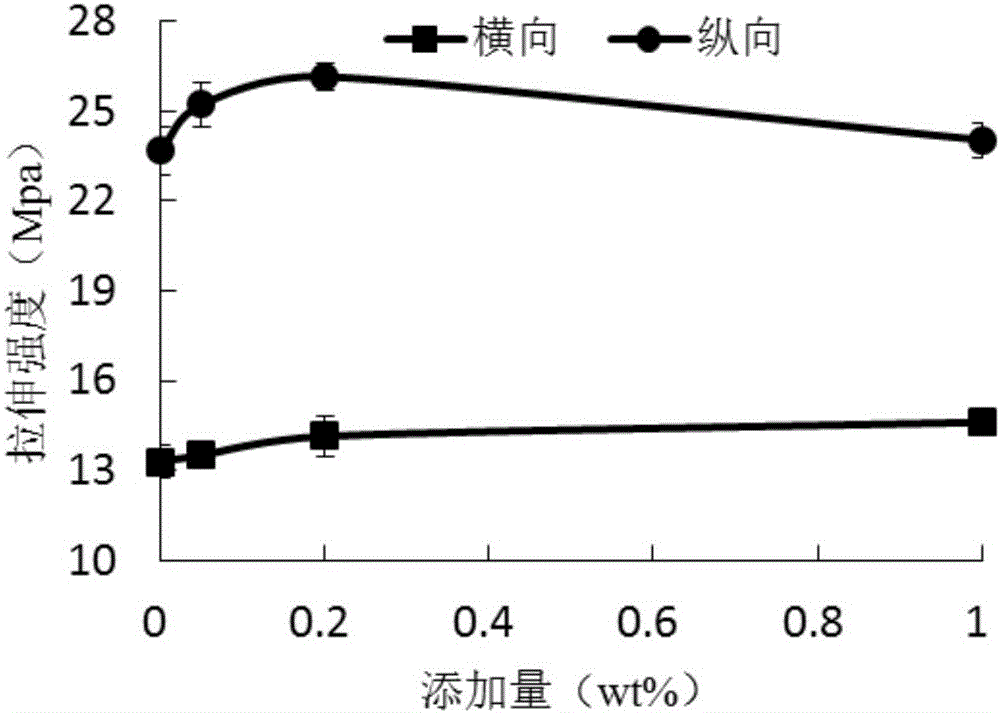

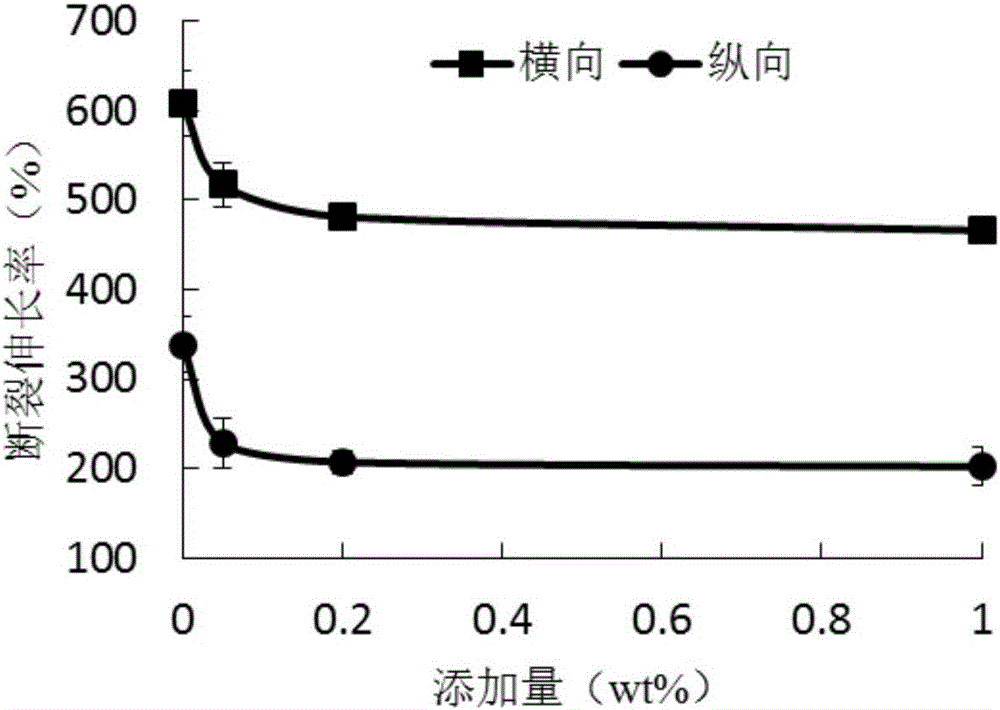

[0035] The graphene / low-density polyethylene composite film that obtains is carried out mechanical prope...

Embodiment 2

[0037] Configure 4 kinds of materials, UV-531+LDPE, UV-531+graphene+LDPE, UV-P+LDPE, UV-P+graphene+LDPE. Wherein the UV-531 and UV-P mass percentages are both 1%, and the graphene mass percentages are both 0.05%. The mixed material is sent into the twin-screw extruder, and the material is fully fused under the shearing, mixing and conveying of the screw, and finally extruded and granulated through the die. This granulation process was repeated twice.

[0038] Twin-screw extruder parameter setting: the temperature of barrel zone 1 to zone 9 is: 150°C, 155°C, 155°C, 160°C, 160°C, 165°C, 165°C, 165°C, 165°C; die head temperature The temperature is 165°C; the screw speed is 150r / min.

[0039] Send the prepared masterbatch into the film blowing machine, and use the method of hollow blow molding to obtain the corresponding film. The temperature of Zone 1-4 of the film blowing machine is 155°C, 160°C, 165°C, 165°C respectively.

[0040] The migration of UV-531 and UV-P to isoocta...

Embodiment 3

[0042]Configure 4 kinds of materials, Irgafos168+LDPE, Irgafos168+graphene+LDPE, Irganox1076+LDPE, Irganox1076+graphene+LDPE. Wherein the mass percent content of Irgafos168 and Irganox1076 is 1%, and the mass percent content of graphene is 0.05%. The mixed material is sent into the twin-screw extruder, and the material is fully fused under the shearing, mixing and conveying of the screw, and finally extruded and granulated through the die. This granulation process was repeated twice.

[0043] Twin-screw extruder parameter setting: the temperature of barrel zone 1 to zone 9 is: 150°C, 155°C, 155°C, 160°C, 160°C, 165°C, 165°C, 165°C, 165°C; die head temperature The temperature is 165°C; the screw speed is 150r / min.

[0044] Send the prepared masterbatch into the film blowing machine, and use the method of hollow blow molding to obtain the corresponding film. The temperature of Zone 1-4 of the film blowing machine is 155°C, 160°C, 165°C, 165°C respectively.

[0045] The migra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com