Solvent for dissolving agarose at low temperature and method for preparing agarose gel

An agarose and solvent technology, which is applied in the fields of natural polymers, environmental engineering, agriculture, and chemistry, can solve the problems of limited application, limited derivatization reaction and processing, instability, etc., and achieves obvious innovation and outstanding room temperature stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 3 grams of agarose powder, add 100 grams of 5 wt% lithium hydroxide monohydrate / 10wt% urea mixed aqueous solution, stir well and put it in the refrigerator to freeze, then stir while thawing, fully melt and centrifuge at 6000rpm for 5 minutes , to obtain a transparent agarose solution.

Embodiment 2

[0018] Weigh 3 grams of agarose powder, add 100 grams of 8 wt% lithium hydroxide monohydrate / 20 wt% urea mixed aqueous solution, stir thoroughly and place in the refrigerator to freeze, then stir while thawing, fully melt and centrifuge at 6000rpm for 5 minutes to obtain a transparent agarose solution.

Embodiment 3

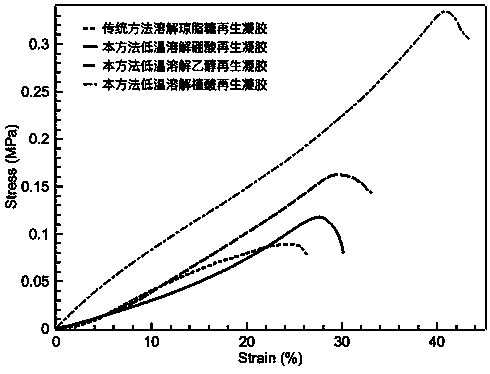

[0020] Weigh 6 grams of agarose powder, add 100 grams of 7 wt% lithium hydroxide monohydrate / 13 wt% urea mixed aqueous solution, vortex and disperse, freeze in the refrigerator, then thaw at room temperature while stirring, and centrifuge at 10,000 rpm After degassing for 5 min, a clear and transparent agarose solution was obtained. Pour the centrifuged solution into the prepared mold, put it into 90% ethanol aqueous solution to solidify and form, and then wash repeatedly to remove excess alkali and urea to obtain a regenerated agarose gel. It can be seen from the scanning electron microscope image of the gel that the surface of the gel is smooth and flat, and has very good uniformity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com