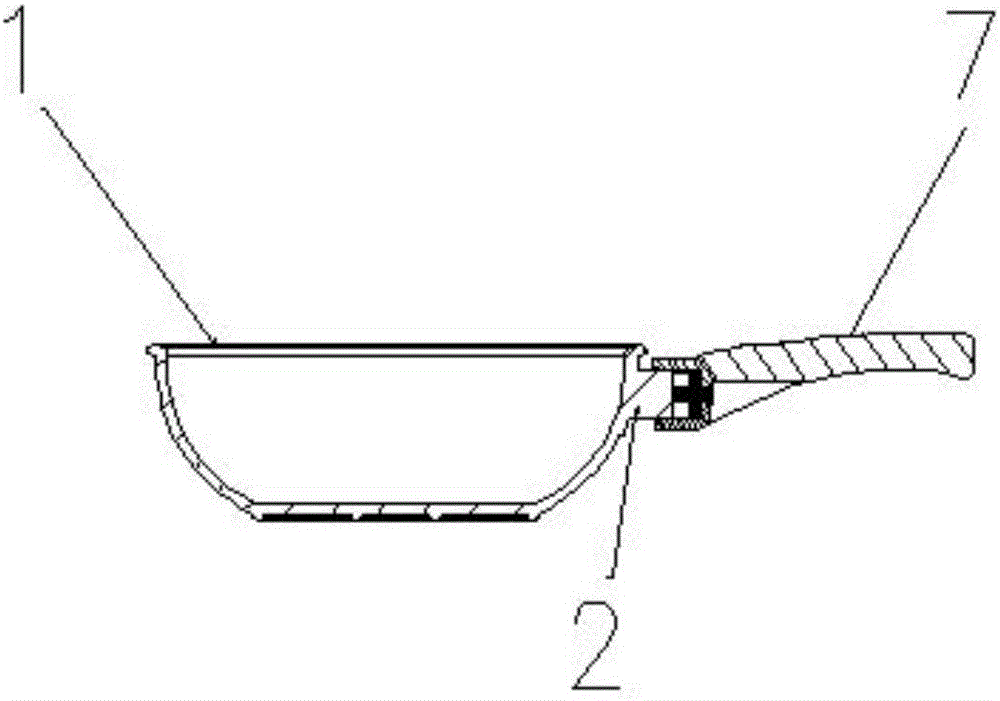

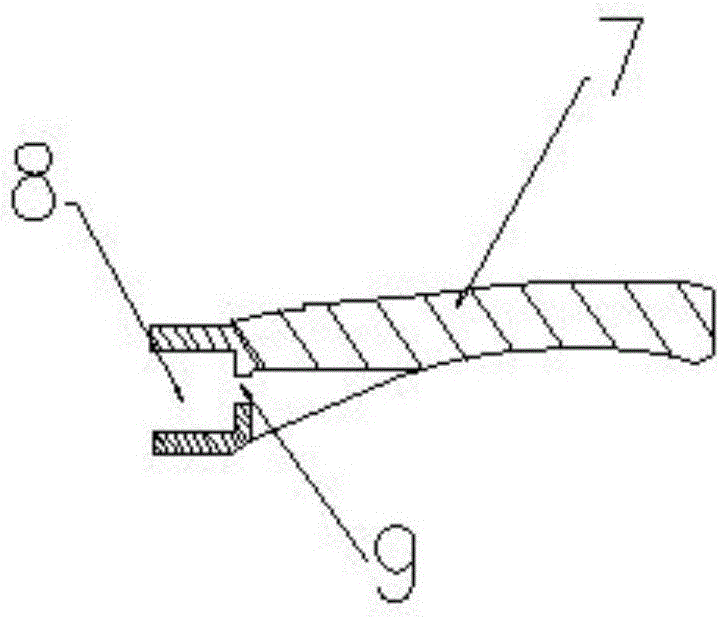

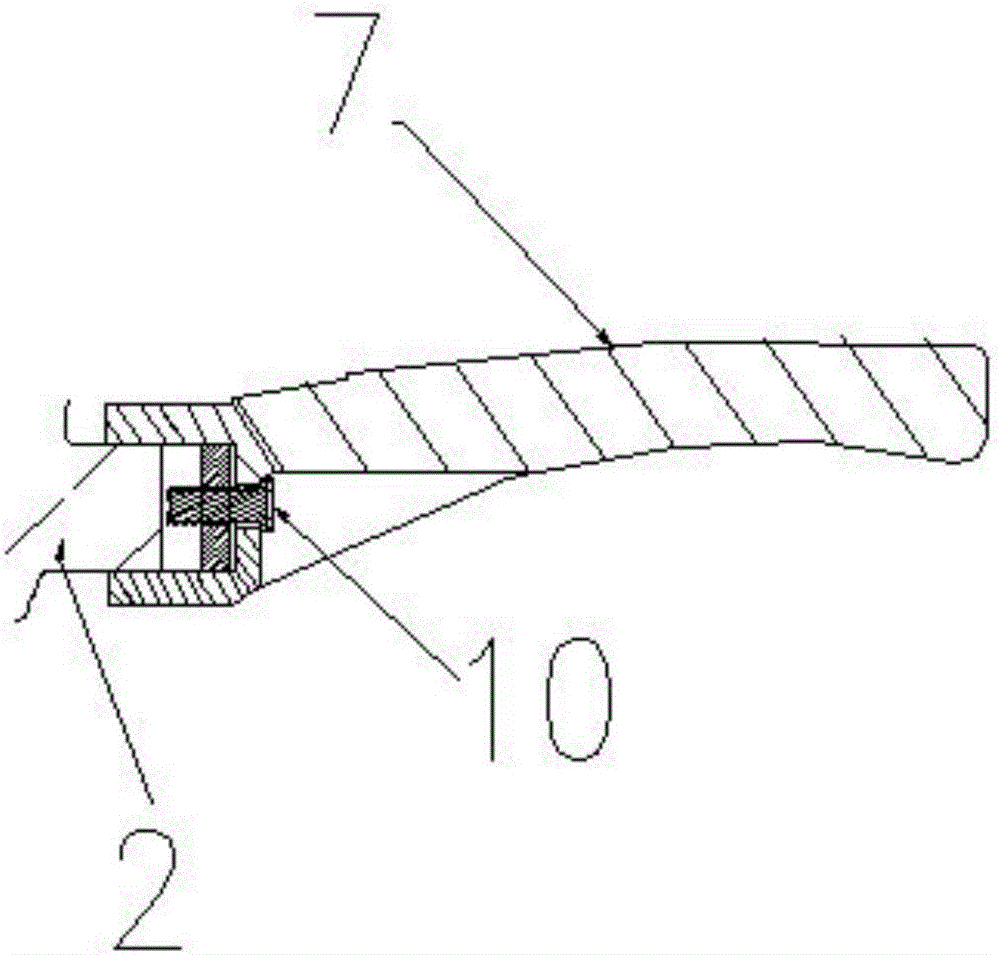

Ceramic pot

A technology for a ceramic pot and a pot body, applied in the field of ceramic pots, can solve the problems that the surface of daily-use ceramic products is not smooth, bright, and old, and achieves the effect of smooth surface, smooth glaze, and good finish.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: described glaze is made up of the raw material of following weight ratio:

[0026] 20 parts of quartz, 12 parts of limestone, 14 parts of kaolin, 36 parts of potassium feldspar, 8.5 parts of barium carbonate, 1 part of zinc oxide, 5.5 parts of talc, 1.4 parts of nano-alumina, 0.2 parts of itaconic acid, sodium tripolyphosphate 0.3 parts, 0.08 parts of sodium carboxymethylcellulose, 0.6 parts of lotus root, 0.5 parts of cinnamon, 1.7 parts of Huoxiang, 0.4 parts of pomegranate peel, 0.2 parts of grape seeds;

[0027] Its preparation method comprises the following steps:

[0028] (1) lotus root, cassia bark, Huoxiang, pomegranate peel, and grape seed are soaked in 1.1% sodium carbonate solution with a mass fraction of 40 parts by weight after soaking for 16 hours, then dried and pulverized to obtain a mixed powder, and then use the mixed powder with 7 times the weight Ultrasonic extraction is carried out on it with a mixed solvent, the ultrasonic extraction...

Embodiment 2

[0032] Embodiment 2: described glaze is made up of the raw material of following weight ratio:

[0033] 18 parts of quartz, 12 parts of limestone, 10 parts of kaolin, 35 parts of potassium feldspar, 8 parts of barium carbonate, 1 part of zinc oxide, 5 parts of talc, 1.2 parts of nano-alumina, 0.1 part of itaconic acid, sodium tripolyphosphate 0.2 parts, 0.05 parts of sodium carboxymethyl cellulose, 0.5 parts of lotus root, 0.3 parts of cinnamon, 1.6 parts of Huoxiang, 0.3 parts of pomegranate peel, 0.1 part of grape seeds;

[0034] Its preparation method comprises the following steps:

[0035] (1) lotus root, cassia bark, Huoxiang, pomegranate peel, and grape seed are soaked in 0.5% sodium carbonate solution with a mass fraction of 30 parts by weight after soaking for 15 hours, then dried and pulverized to obtain mixed powder, and then mixed with 6 times the weight of the mixed powder ultrasonic extraction with a mixed solvent of 100KHz, stirring and extracting for 50min at a...

Embodiment 3

[0039] Embodiment 3: described glaze is made up of the raw material of following weight ratio:

[0040] 21 parts of quartz, 14 parts of limestone, 15 parts of kaolin, 38 parts of potassium feldspar, 9 parts of barium carbonate, 2 parts of zinc oxide, 6 parts of talc, 1.5 parts of nano-aluminum oxide, 0.3 parts of itaconic acid, sodium tripolyphosphate 0.5 parts, 0.1 parts of sodium carboxymethylcellulose, 0.8 parts of lotus root, 0.6 parts of cinnamon, 2.0 parts of Huoxiang, 0.9 parts of pomegranate peel, 0.3 parts of grape seeds;

[0041] Its preparation method comprises the following steps:

[0042] (1) lotus root, cassia bark, Huoxiang, pomegranate peel, and grape seed are soaked in 1.5% sodium carbonate solution for 20h with a mass fraction of 50 parts by weight, dried, and mixed powder is obtained after pulverization, and then mixed powder is mixed with 8 times the weight ultrasonic extraction with a mixed solvent of 100KHz, stirring and extracting for 60min at a rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com