Laser drilling machining method

A laser perforation and processing method technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of step-by-step perforation affecting perforation efficiency, prone to explosion, and disproportionate increase in perforation time, etc. The generation of laser-induced plasma, the improvement of perforation efficiency and stability, and the effect of reducing laser power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

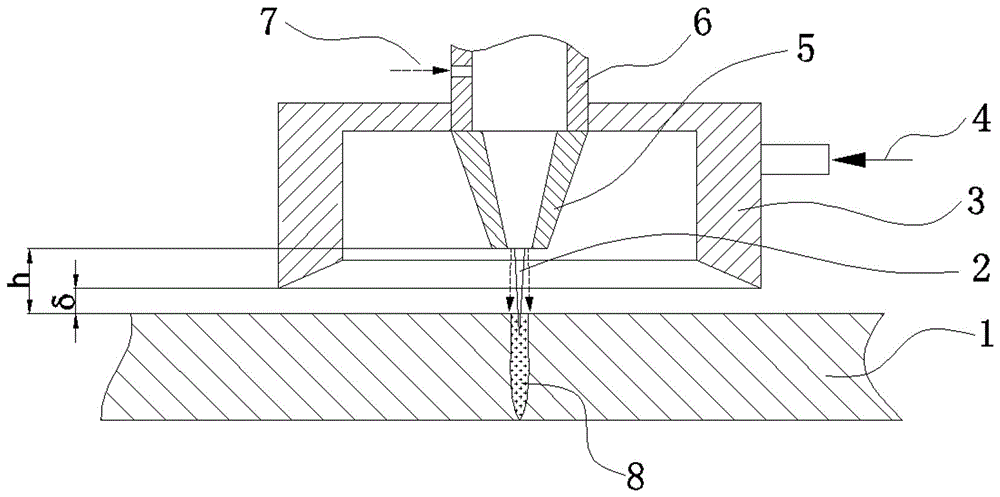

[0033] Such as figure 1 As shown, the workpiece to be cut is a carbon steel plate with a thickness of 20 mm to 35 mm. The vacuum cover installed on the cutting head forms a partial vacuum environment in the laser cutting perforation area. During the laser perforation process, the material has a strong melting ability, and the vapor pressure of the metal vapor in the perforation small hole is low, which avoids the formation of a large amount of molten metal sprayed upwards. Hole blasting realizes high-quality perforation processing.

[0034] In this embodiment, the laser drilling method includes the following steps.

[0035] Step 1: remove impurities on the upper surface of the workpiece 1 to be cut, and these impurities include water stains, oil stains, rust and other impurities that affect the welding quality.

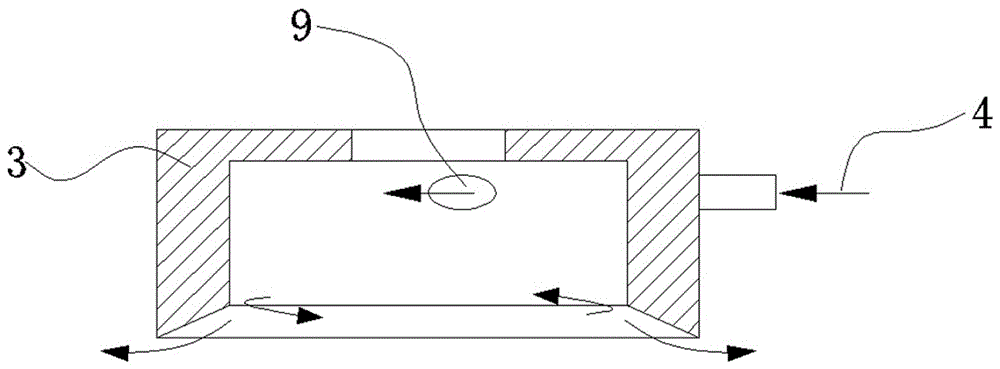

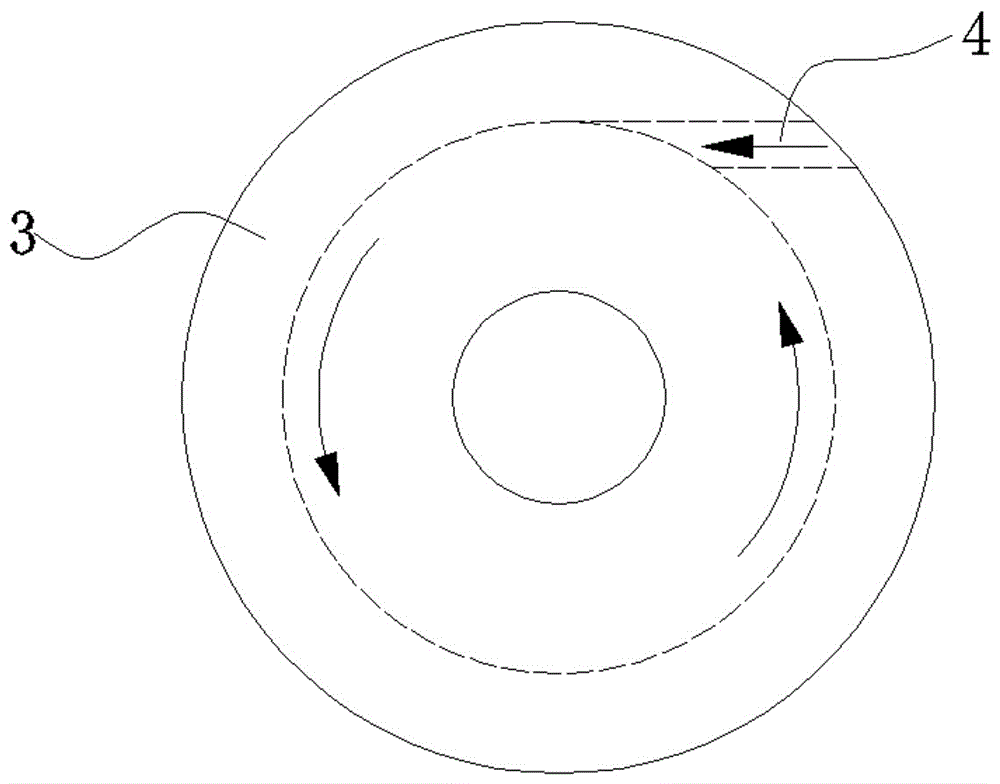

[0036] Step 2: Connect the cyclone vacuum cover 3 to the laser cutting head 6, the vacuum cover 3 can rotate on the laser cutting head 6, and the distance between t...

specific Embodiment approach 2

[0044] Such as figure 1 As shown, the workpiece to be cut is a stainless steel plate with a thickness of 15 mm to 25 mm. The vacuum cover installed on the cutting head forms a partial vacuum environment in the laser cutting perforation area. During the laser perforation process, the material has a strong melting ability, and the vapor pressure of the metal vapor in the perforation small hole is low, which avoids the formation of a large amount of molten metal sprayed upwards. Hole blasting realizes high-quality perforation processing.

[0045] In this embodiment, the laser drilling method includes the following steps.

[0046] Step 1: remove impurities on the upper surface of the workpiece 1 to be cut, and these impurities include water stains, oil stains, rust and other impurities that affect the welding quality.

[0047] Step 2: Connect the cyclone vacuum cover 3 to the laser cutting head 6, the vacuum cover 3 can rotate on the laser cutting head 6, and the distance between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com