Ignition system for fuel gas generator

A gas generator and ignition system technology, applied in the field of ignition systems, can solve problems such as potential safety hazards and loss of ignition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

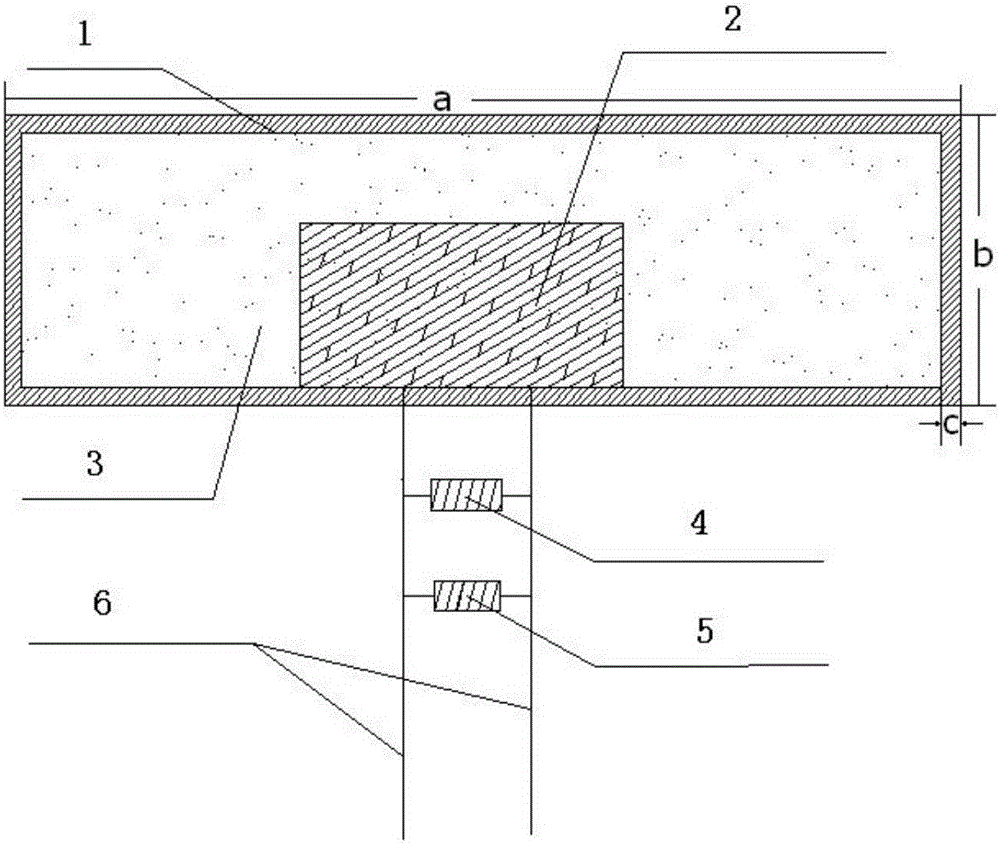

[0015] The ignition kit is made of nitrocellulose products, the thickness c of the kit is 0.5mm, the size of the kit is: the diameter a of the ignition kit is 30mm, the height b of the ignition kit is 5mm, the ignition powder is granular ignition powder, the dosage is 8g, and the ignition tube The connecting line is connected to the conductive rod on the combustion chamber, and a current protection chip and a radio frequency protection chip are installed in the middle. Give a certain range of ignition current to the ignition tube, and the number of test samples in this group is 30.

[0016] Test results: 30 ignition devices were successfully ignited, and the ignition current was within a certain range, meeting the requirements of GB16668-2010.

Embodiment 2

[0018] The ignition kit is made of nitrocellulose products. The thickness of the kit is 0.5mm. The size of the kit is φ30mm and the height is 5mm. Installed current protection chip and radio frequency protection chip. After testing for 90 days at a temperature of 90°C±2°C, apply an ignition current within a certain range to the ignition tube. The number of test samples in this group is 30.

[0019] Test results: 30 ignition devices were successfully ignited, and the ignition current was within a certain range, meeting the requirements of GB16668-2010.

Embodiment 3

[0021] The ignition kit is made of nitrocellulose products. The thickness of the kit is 0.5mm. The size of the kit is φ30mm and the height is 8mm. A current protection chip and a radio frequency protection chip are added. After testing for 90 days at a temperature of 40°C±2°C and a relative humidity of 95%, apply an ignition current within a certain range to the ignition tube. The number of test samples in this group is 30.

[0022] Test results: 30 ignition devices were successfully ignited, and the ignition current was within a certain range, meeting the requirements of GB16668-2010.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com