Magnesium sulfate and red mud sound insulation and noise reduction decorative plate and preparing method thereof

A magnesium sulfate and decorative board technology, applied in the field of building materials, can solve the problems of bulky and thick, occupied volume, single noise reduction form, etc., achieves good compartment effect, uniform thickness of the board, and improves the effect of sound absorption and noise reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

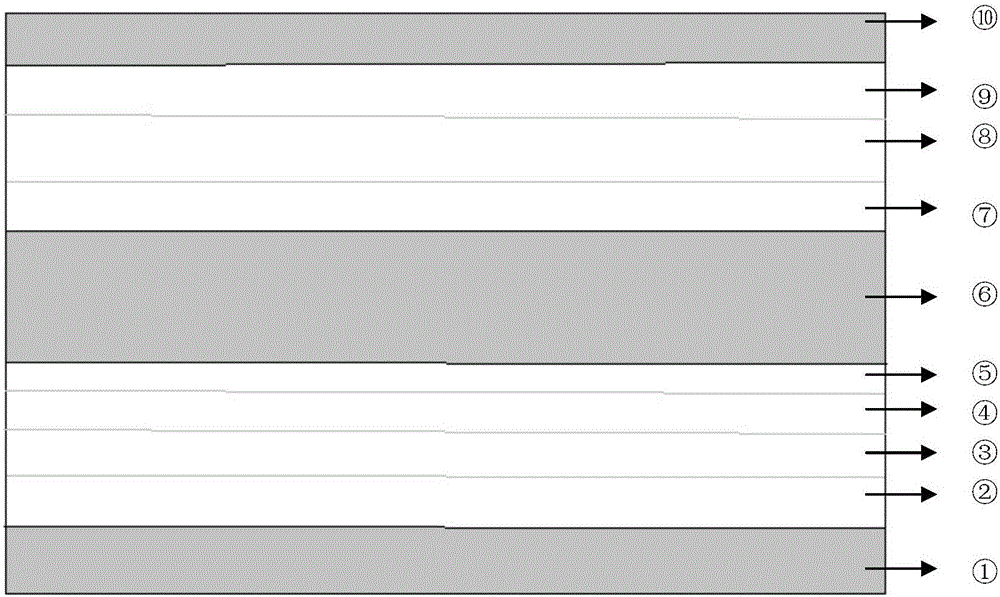

[0044] According to the manual attached figure 1 , to prepare a decorative board.

[0045] The composition of the base layer is: light-burned magnesia: 100 parts; magnesium sulfate heptahydrate: 60 parts; water: 70 parts; talcum powder: 60 parts; latex powder: 15 parts; red mud: 20 parts; modifier : 5 parts; 10 parts of iron oxide red.

[0046] The composition of the middle material layer is: light-burned magnesia: 100 parts; magnesium sulfate heptahydrate: 80 parts; water: 100 parts; red mud: 20 parts; wood chips: 60 parts; perlite: 40 parts; modifier: 5 parts parts; 10 parts of iron oxide red.

[0047] The composition of the sanding layer is: light-burned magnesia: 100 parts; magnesium sulfate heptahydrate: 80 parts; water: 100 parts; wood flour: 60 parts; defoamer: 2 parts; modifier: 5 parts; iron oxide Red 10 parts.

[0048] The preparation steps are as follows:

[0049] Bottom slurry layer: Add magnesium sulfate heptahydrate and water in proportion and stir until mag...

Embodiment 2

[0064] According to the manual attached figure 1 , to prepare a decorative board.

[0065] The composition of the base layer is: light-burned magnesia: 100 parts; magnesium sulfate heptahydrate: 40 parts; water: 50 parts; talcum powder: 20 parts; latex powder: 6 parts; red mud: 30 parts; modifier : 1 part; 3 parts of iron oxide green.

[0066] The composition of the middle material layer is: light-burned magnesia: 100 parts; magnesium sulfate heptahydrate: 40 parts; water: 60 parts; red mud: 30 parts; wood chips: 20 parts; perlite filler: 4 parts; : 1 part; 1 part of iron oxide green.

[0067] The composition of the sanding layer is: light-burned magnesia: 100 parts; magnesium sulfate heptahydrate: 40 parts; water: 60 parts; wood flour: 20 parts; defoamer: 0.5 parts; modifier: 1 part; iron oxide 1 serving of green.

[0068] The preparation steps are as follows:

[0069] Bottom slurry layer: Add magnesium sulfate heptahydrate and water in proportion and stir until magnesiu...

Embodiment 3

[0084] According to the manual attached figure 1 , to prepare a decorative board.

[0085] The composition of the base layer is: light-burned magnesia: 100 parts; magnesium sulfate heptahydrate: 50 parts; water: 60 parts; talcum powder: 40 parts; latex powder: 10 parts; red mud: 25 parts; modifier : 3 parts; 5 parts of iron oxide blue.

[0086] The composition of the middle material layer is: light-burned magnesia: 100 parts; magnesium sulfate heptahydrate: 60 parts; water: 80 parts; sawdust: 40 parts; red mud: 25 parts; other fillers: 30 parts; modifier: 3 parts; 5 parts of iron oxide blue.

[0087] The composition of the sanding layer is: light-burned magnesia: 100 parts; magnesium sulfate heptahydrate: 60 parts; water: 80 parts; wood flour: 40 parts; defoamer: 1 part; modifier: 3 parts; iron oxide Blue 5 copies.

[0088] The preparation steps are as follows:

[0089] Bottom slurry layer: Add magnesium sulfate heptahydrate and water in proportion and stir until magnesiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com