Method for polycrystalline silicon ingot casting

A polysilicon ingot furnace and polysilicon technology, applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of high oxygen content in ingot products, difficulty in getting rid of crucible gas, and low melting efficiency. The effect of low input cost, heat reduction, and easy fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

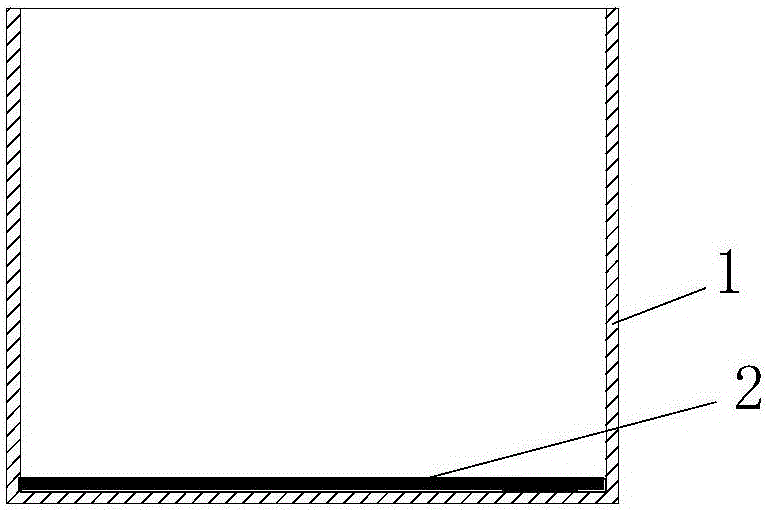

[0080] Such as figure 1 A kind of polysilicon ingot casting method of the present invention shown, this method comprises the following steps:

[0081] Step 1, auxiliary heater installation: install the auxiliary heater in the polysilicon ingot furnace 9;

[0082] Such as Figure 5 and Figure 6 As shown, the auxiliary heater is a bottom heater 3 arranged below the crucible 1, the crucible 1 is a cubic crucible and it is arranged horizontally, the bottom heater 3, and the top heater 2 arranged above the crucible 1 and four side heaters 4 respectively arranged on the outside of the four side walls of the crucible 1 form a six-sided heating device; the top heater 2 and the bottom heater 3 are all arranged horizontally, and the four side heaters 4 are arranged vertically; the top heater 2, the bottom heater 3 and the four side heaters 4 are all arranged in the polysilicon ingot furnace 9;

[0083] Step 2, charging: loading silicon material into the crucible 1, and loading the ...

Embodiment 2

[0200] In this example, the difference from Example 1 is that in step 101, the organic binder, deionized water and boron nitride are uniformly mixed at a mass ratio of 1:2:0.8 to obtain a coating spray solution; the organic binder The agent is a silicone adhesive; when spraying in step 102, the inner bottom surface of the crucible 1 is 1m 2 The mass of boron nitride contained in the coating spray liquid sprayed in the area is 100g; when drying in step 103, the drying equipment is used to spray on the inner bottom surface of the crucible 1 at a temperature of 80°C The coating spray liquid is dried, and the crucible 1 is heated to 80° C. by the drying equipment, and then kept warm until the coating spray liquid sprayed on the inner bottom surface of the crucible 1 is dried; the steps The preheating time in the third step is 4h and T1=1285°C, P1=100kW; T2=1400°C in step 401, T3=1560°C in step 402, t=20min in step 403, P2=45kW; Q2=650mbar in step 4 ; In the first step, the holdin...

Embodiment 3

[0210] In this example, the difference from Example 1 is that in step 101, the organic binder, deionized water and boron nitride are uniformly mixed in a mass ratio of 1:2.5:0.8 to obtain a coating spray solution; the organic binder The agent is an epoxy adhesive; when spraying in step 102, the inner bottom surface of the crucible 1 is 1m 2 The mass of boron nitride contained in the coating spray liquid sprayed in the area is 130g; when drying in step 103, the drying equipment is used to spray on the inner bottom surface of the crucible 1 at a temperature of 100°C Dry the coating spray liquid, and first use the drying equipment to heat the crucible 1 to 100°C, and then keep it warm until the coating spray liquid sprayed on the inner bottom surface of the crucible 1 is dried; step The preheating time in the third step is 6h and T1=1125°C, P1=50kW; T2=1350°C in step 401, T3=1540°C in step 402, t=40min in step 403, P2=25kW; Q2=550mbar in step 4 ; In the first step, the holding t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Life expectancy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com