Direct preparation method of graphene/metal or alloy composite material

A composite material, graphene technology, applied in the direction of metal material coating process, polycrystalline material growth, chemical instruments and methods, etc., can solve the problems of reduced quality and functional characteristics, graphene edge damage, graphene quality degradation and other problems, Achieve the effect of eliminating the destruction of graphene quality, rapid preparation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

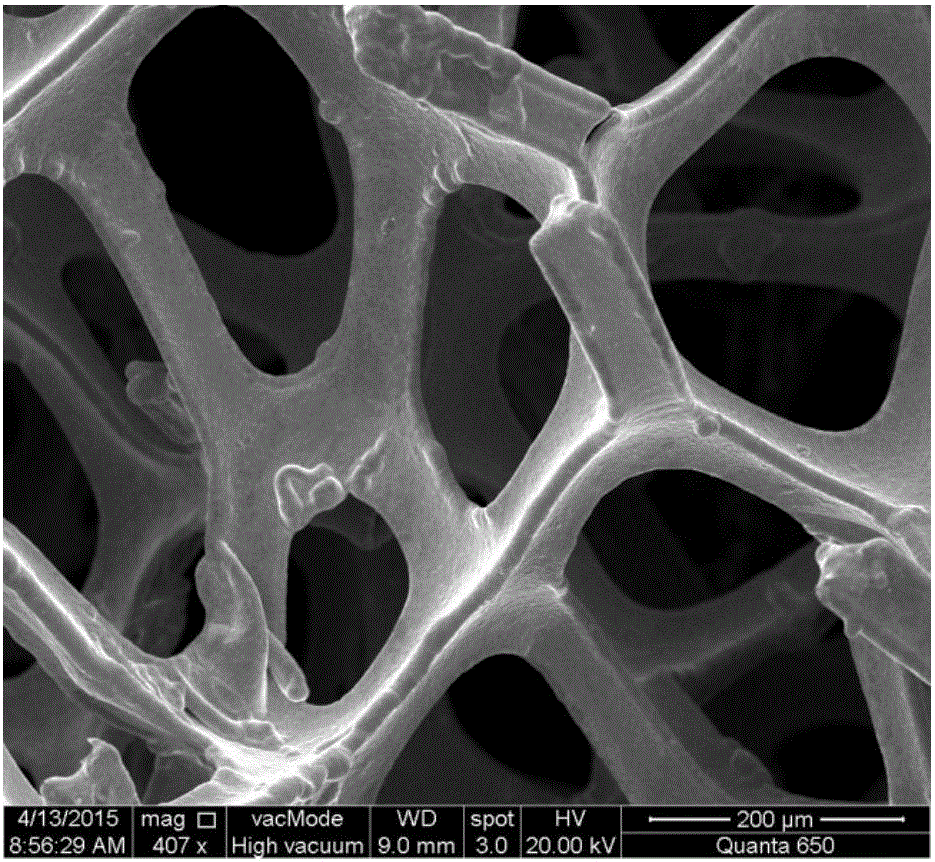

[0038] The direct preparation method of graphene / metal or alloy composite material of the present invention, comprises the steps:

[0039] (1), use dilute acid to clean the oxide layer and impurities on the surface of the metal (alloy) foil, then use deionized water and acetone to ultrasonically clean the metal (alloy) substrate, and dry; wherein the type of dilute acid is dilute Hydrochloric acid, acetic acid or hypochlorous acid, the concentration of dilute acid is 0.01mol / L~0.05mol / L.

[0040] (2) Remove the oxide layer on the surface of the metal or alloy. The specific method is: place the metal or alloy in the constant temperature heating zone of the quartz tube of the CVD reaction furnace, and evacuate it to below 1Pa, and then pour protective gas into the quartz tube to rinse repeatedly for 3 ~5 times to ensure that there is no air in the quartz tube, then open the CVD reaction furnace to raise the temperature to the set temperature, then pass protective gas and reducin...

Embodiment 1

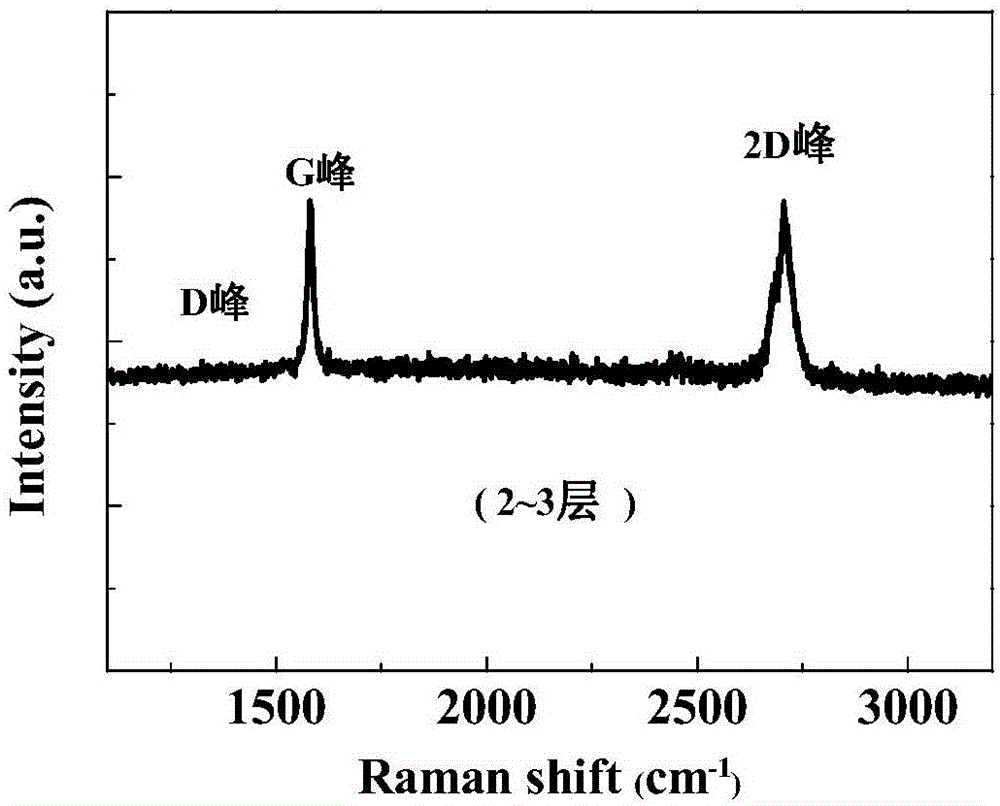

[0050] Step 1: Use hydrochloric acid with a concentration of 0.01mol / L to clean the oxide layer and impurities on the surface of the Ni foil, then use deionized water and acetone to ultrasonically clean the Ni foil substrate, and dry it.

[0051] Step 2: Place the treated Ni foil (4cm×4cm) substrate in the constant temperature heating zone of the quartz tube of the CVD reaction furnace, and evacuate to below 1Pa.

[0052] Step 3: Inject nitrogen gas into the quartz tube and rinse repeatedly 3 to 5 times to ensure that there is no air in the quartz tube, then turn on the CVD reactor and heat up to 850°C, and then inject nitrogen and hydrogen into the quartz tube for 20 minutes, with mass flow rates of 600 sccm and 100 sccm respectively , keep the pressure inside the quartz tube at 10Pa, and remove the fresh NiO layer on the surface of the Ni foil.

[0053] Step 4: According to the melting point of Ni metal, heat to 1050° C., keep the pressure in the quartz tube as 10 Pa, and fe...

Embodiment 2

[0060] Step 1: Clean the oxide layer and impurities on the surface of the Ti foil with 0.05 mol / L acetic acid, then ultrasonically clean the Ti substrate with deionized water and acetone, and dry it.

[0061] Step 2: Place the treated Ti foil (2cm×2cm) substrate in the constant temperature heating zone of the quartz tube of the CVD reaction furnace, and evacuate to below 1Pa.

[0062] Step 3: Inject helium into the quartz tube and rinse repeatedly 3 to 5 times to ensure that there is no air in the quartz tube, then turn on the CVD reaction furnace and raise the temperature to 900°C, then inject helium and carbon monoxide into the quartz tube for 10 minutes, with a mass flow rate of 500 sccm respectively and 150sccm, keep the pressure inside the quartz tube at 50Pa, remove the fresh TiO on the surface of the Ti foil 2 layer.

[0063] Step 4: According to the melting point of Ti metal, heat to 1100° C., keep the pressure in the quartz tube at 50 Pa, and feed helium and propane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com