Heat conducting pouring sealant material and preparation method thereof

A heat-conducting potting and heat-conducting powder technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of insufficient thermal conductivity and insufficient density, and achieve low density and good thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

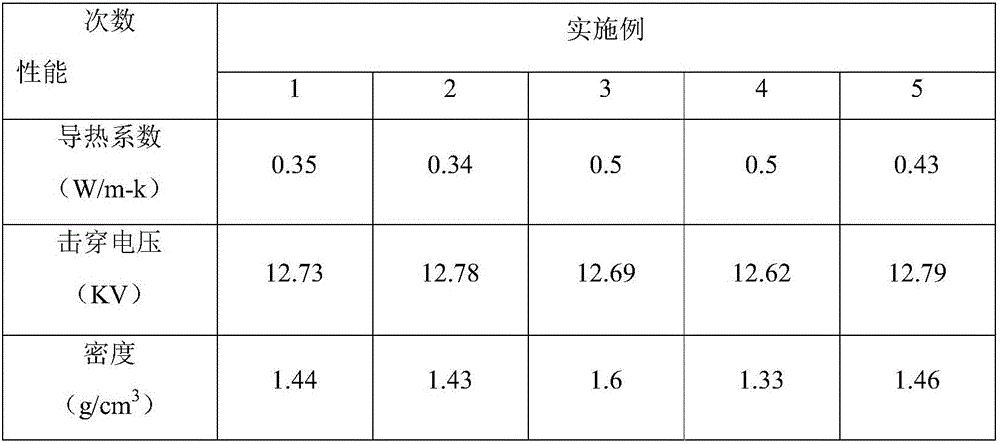

Examples

preparation example Construction

[0049] The preparation method of the heat-conducting potting adhesive material of the present invention is formed by mixing various raw materials.

[0050] In the above preparation method, the mixing method can be implemented by using a high-speed disperser or a planetary stirring device. Specifically, the rotational speed of mixing by a high-speed disperser can be controlled at 800-3000 rpm, and the mixing time is 30-100 minutes. The speed of mixing with planetary mixing equipment can be controlled at 30-80rpm, and the mixing time is 30-100min.

[0051] In the mixing step, the product can also be vacuum defoamed.

Embodiment 1

[0053] First, the ratio of raw materials. Specifically: 50g of a mixture composed of vinyl silicone oil and hydrogen-containing silicone oil, 50g of vinyl silicone oil, 100g of alumina powder (D 50 35μm), 3g airgel, 0.2g coupling agent, 30g flame retardant.

[0054] Both the alumina powder and the airgel are dried, and then the surface is treated with a coupling agent according to a conventional method. Then, the aluminum oxide powder and the airgel are respectively added into the silicone polymer, stirred in a double planetary mixer for 50-60 minutes, and vacuum degassed to form A component and B component. Finally, mix A / B component 1:1 evenly, pour into the mold, and solidify at room temperature or heat.

Embodiment 2

[0056] First, the ratio of raw materials. Specifically: 50g of a mixture composed of vinyl silicone oil and hydrogen-containing silicone oil, 50g of vinyl silicone oil, 100g of alumina powder (D 50 35μm), 3g glass beads (D 50 65μm), 0.2g coupling agent, 30g flame retardant.

[0057] Both the alumina powder and the airgel are dried, and then the surface is treated with a coupling agent according to a conventional method. Then, the aluminum oxide powder and the airgel are respectively added into the silicone polymer, stirred in a double planetary mixer for 50-60 minutes, and vacuum degassed to form A component and B component. Finally, mix A / B component 1:1 evenly, pour into the mold, and solidify at room temperature or heat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com