Hot melt adhesive for paper diaper and preparation method thereof

A technology for hot melt adhesive and diapers, which is applied in the directions of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of irritating taste, poor bonding strength, etc. The effect of hot melt adhesive force and good antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in conjunction with specific embodiments.

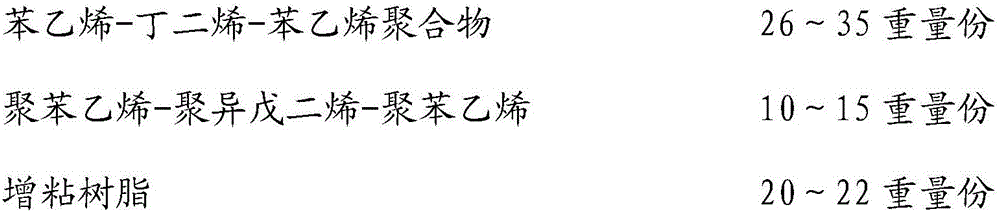

[0020] The first embodiment provides a hot melt adhesive for diapers, which consists of the following raw materials in parts by weight:

[0021]

[0022]

[0023] The content of styrene in the styrene-butadiene-styrene polymer is 25%.

[0024] The preparation method of the hot-melt adhesive for paper diapers of present embodiment 1 comprises the following steps:

[0025] The first step is to heat the microcrystalline wax, nano activated carbon powder, and tackifying resin to melt and stir evenly, and heat to a temperature of 220°C;

[0026] In the second step, continue to add styrene-butadiene-styrene polymer, polystyrene-polyisoprene-polystyrene, mix and stir evenly, and heat for 5 minutes;

[0027] The third step is to continue to put in liquid plasticizer and antioxidant, mix and stir evenly, and heat for 15 minutes;

[0028] The fourth step is to continue to add 1 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com