Core-shell polymer suitable for oilfield produced water and preparation method of core-shell polymer

A technology of polymer and produced water, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor shear resistance of HPAM, and achieve the effect of outstanding economic benefits and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

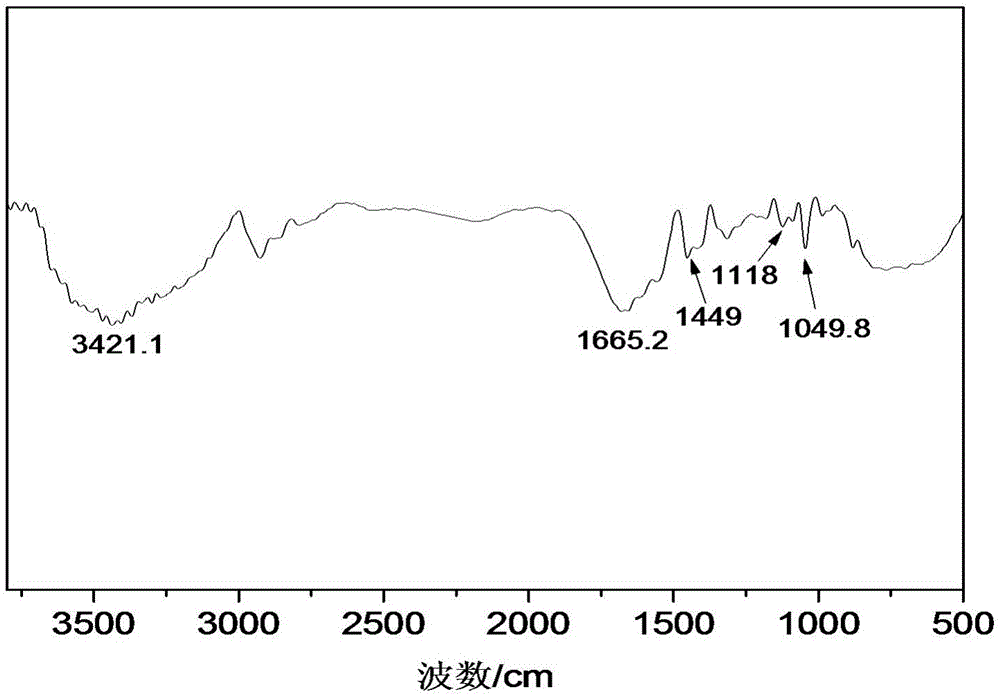

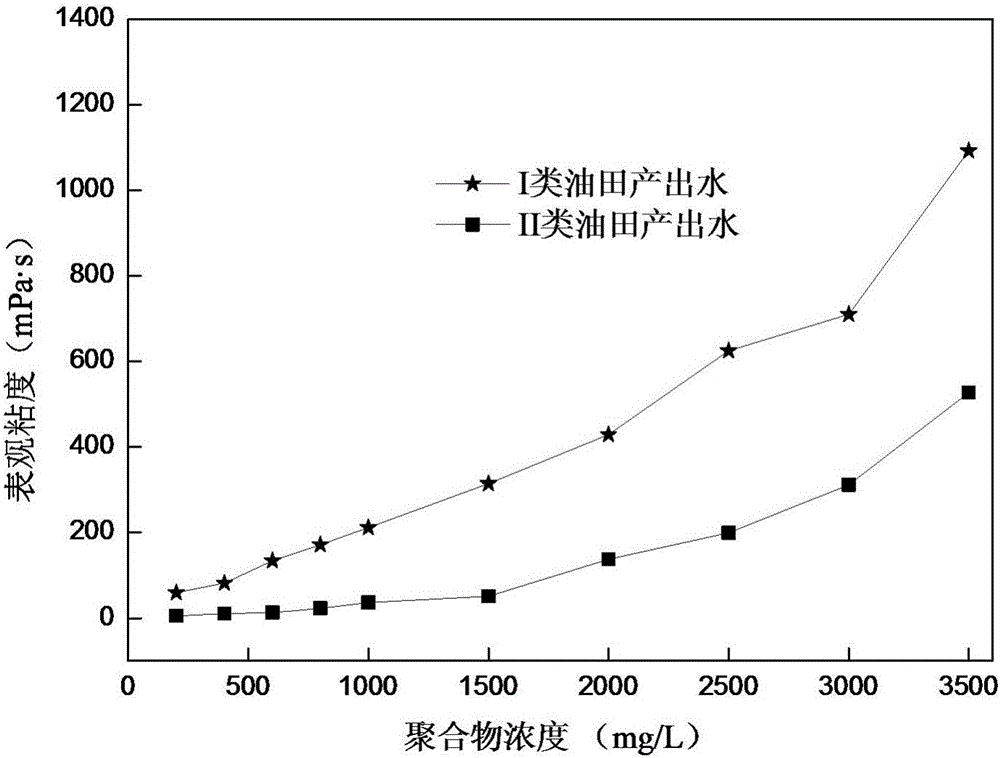

Image

Examples

Embodiment 1

[0035] Embodiment 1 methyl-N, the preparation of N-dihexyl twin tail core-shell polymer

[0036] (1) Surface modification of ultrafine silicon dioxide by coupling agent: add 12.5g nanometer silicon dioxide and 130g methanol into a three-necked bottle, disperse with ultrasonic vibration for 30min, add 13.5g vinyltrimethoxysilane and Stir, react at a temperature of 60°C for 8 hours, cool, wash with methanol, vacuum filter, and dry to obtain surface-modified ultrafine silica;

[0037] (2) Polyamide-amine hybrid ultrafine silica: add 6.0g of surface-modified ultrafine silica and 85g of methanol into a three-necked bottle, disperse by ultrasonic oscillation for 30min, add 1.0 generation polyamide- Stir 5.6g of amine, react at 25°C for 6h, wash with methanol, vacuum filter, and dry to obtain polyamide-amine hybrid ultrafine silica;

[0038] (3) Functional modification of polyamide-amine hybrid ultrafine silica: 3.8g polyamide-amine hybrid ultrafine silica and 38g dimethyl sulfoxide...

Embodiment 2

[0043] Embodiment 2 methyl-N, the preparation of N-dioctyl twin-tail core-shell polymer

[0044] (1) Surface modification of ultra-fine silica by coupling agent: add 15g nanometer silica and 150g methanol into a three-neck bottle, disperse by ultrasonic oscillation for 30min, add 15g of coupling agent vinyltrimethoxysilane and stirred, reacted at a temperature of 60°C for 8 hours, cooled, washed with methanol, vacuum filtered, and dried to obtain surface-modified ultrafine silica;

[0045] (2) Polyamide-amine hybrid ultra-fine silica: add 8.0g of surface-modified ultra-fine silica and 100g of methanol into a three-necked bottle, disperse by ultrasonic oscillation for 30min, add 1.0 generation polyamide- Stir 8.5g of amine, react at 25°C for 8h, wash with methanol, vacuum filter, and dry to obtain polyamide-amine hybrid ultrafine silica;

[0046] (3) Functional modification of polyamide-amine hybrid ultrafine silica: 4.2g polyamide-amine hybrid ultrafine silica and 45g dimethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com